Garden waste incineration boiler

A garden waste and boiler technology, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as low resource utilization, achieve efficient treatment, avoid furnace shutdown, and avoid overheating and burnout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

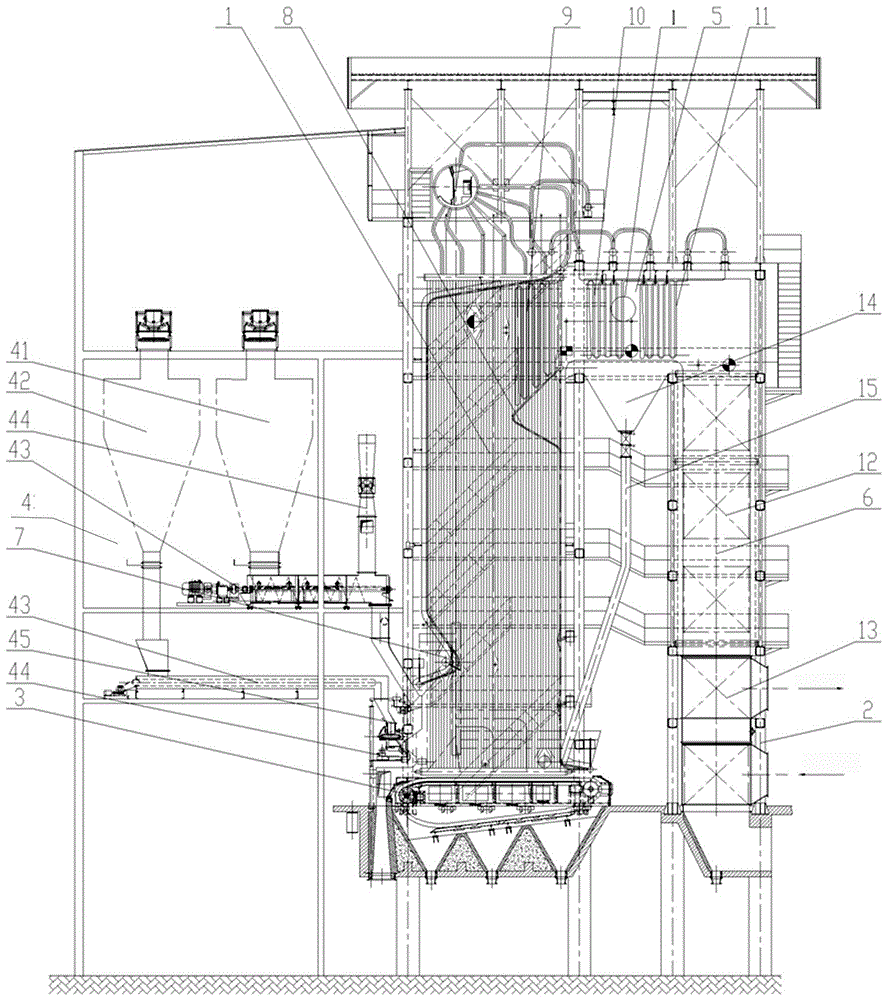

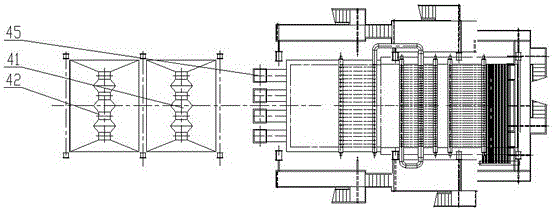

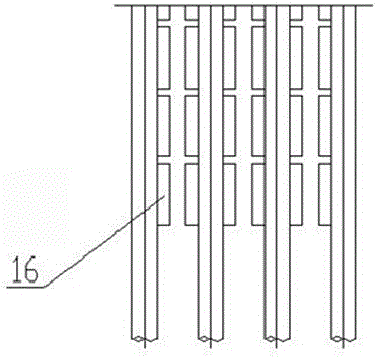

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] like figure 1 As shown, the garden waste incineration boiler of the present invention includes a furnace 1, a steel frame 2, a fire grate 3, a feeding system 4, a horizontal flue 5 and a tail flue 6. The furnace 1 is installed on a steel frame 2 , and the fire grate 3 is arranged below the furnace 1 . The grate 3 is an inverted chain grate, and the grate pieces are made of heat-resistant cast steel. Behind the furnace 1, a horizontal flue 5 and a tail flue 6 are arranged in sequence, and are arranged in a "Xiang" shape. A feeding system 4 is arranged at the front of the furnace 1 . A water-cooled front arch 7 is arranged under the front part of the furnace 1, and the lower edge of the outlet of the furnace 1 protrudes into the furnace to form a flame-folding angle 8. A high temperature superheater 9 is arranged above the folded flame angle 8 at the outlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com