Lamination fabrication method of dielectric functionally graded insulator

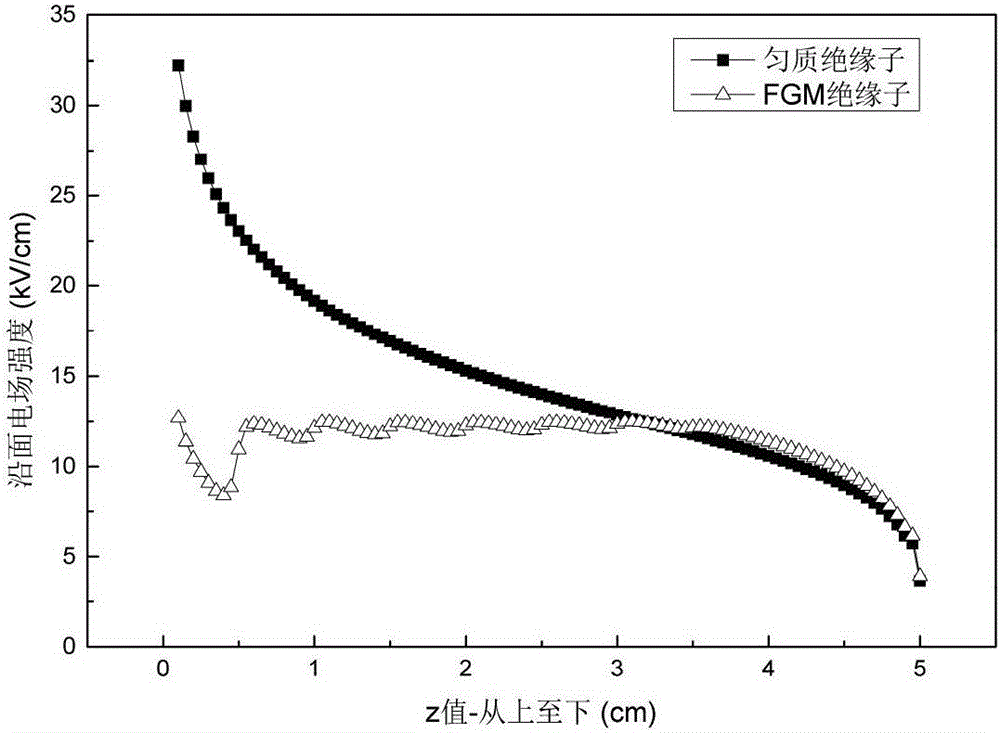

A technology of functional gradient and laminated manufacturing, applied in the direction of insulators, electronic equipment, chemical instruments and methods, etc., can solve the problems of inapplicable insulators, achieve the effect of improving electrical resistance and optimizing electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

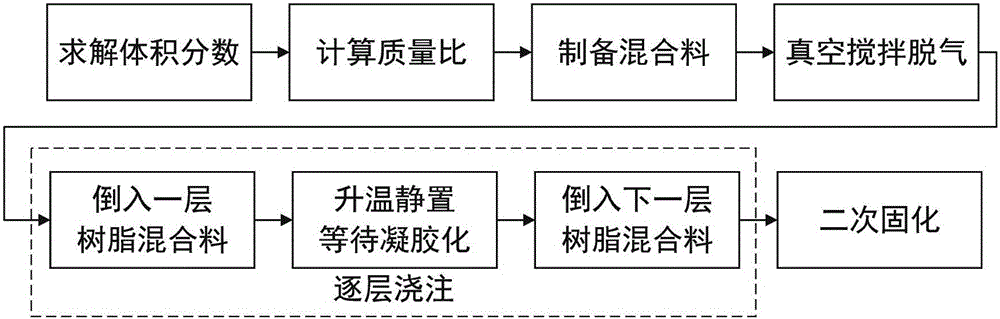

[0035] see figure 1 As shown, the laminated manufacturing method of the dielectric functionally graded insulator of the present invention comprises the following steps:

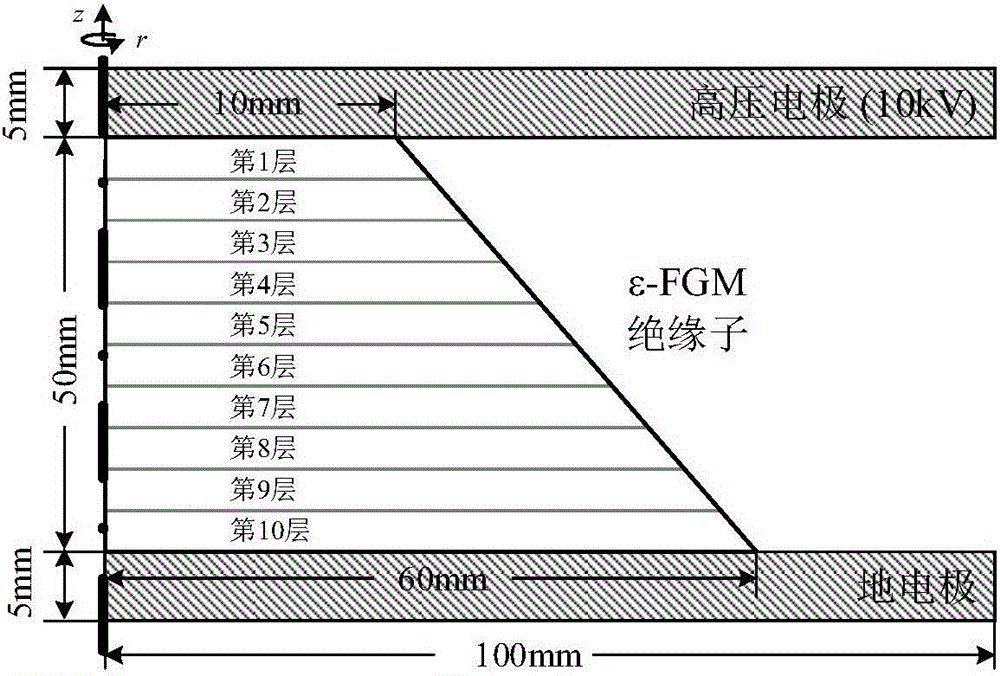

[0036] Step 1. Divide the insulator into several layers, each layer is composed of resin mixture mixed with resin matrix and filler; the dielectric parameter values of several layers are distributed in gradient, and the resin mixture of each layer is calculated according to the dielectric parameter value of each layer Filler volume fraction in the material;

[0037] Step 2, the resin matrix contains epoxy resin and curing agent, the mass ratio of the two is 100:30-100; according to the volume fraction of fillers in the resin mixture of each layer, combined with the density values of various raw materials in the resin mixture, calculate the Raw material mass ratio of layer resin mixture;

[0038] Step 3, according to the raw material mass ratio of each layer of resin mixture calculated in step 2, prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com