Full-temperature-process pressure swing adsorption method for recycling hydrocarbons from low-temperature methyl alcohol washing tail gas

A low-temperature methanol washing, pressure swing adsorption technology, applied in separation methods, chemical instruments and methods, gas treatment and other directions, can solve the problems of difficult TSA adsorption and regeneration cycle, difficult PSA adsorption, etc., to overcome the high energy consumption of regeneration, The effect of prolonging life and solving technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

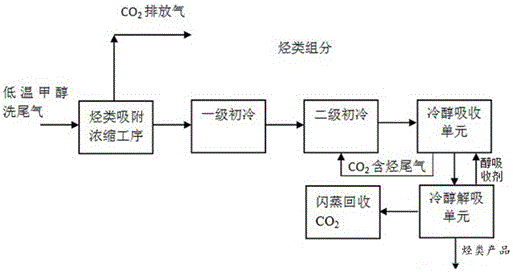

[0036] Such as figure 1 As shown, a full temperature range pressure swing adsorption (FTrPSA) method for recovering hydrocarbons from low-temperature methanol scrubbing tail gas, the steps of the method are as follows:

[0037] (1) Hydrocarbon adsorption and concentration process

[0038] a. Atmospheric low-temperature methanol scrubbing tail gas is composed of non-methane hydrocarbons content of 0.6% (volume ratio, the same below), N 2 10.1%, CO 2 It is 88.0%, and the rest is 1.3%; the feed temperature is 40-50°C, and the feed flow rate is 600,000 cubic meters per hour;

[0039] b. After the low-temperature methanol washing tail gas passes through the fan and adjusts the pressure, it enters from the bottom of the adsorption tower and then performs adsorption. The adsorption pressure is 40-50KPa, and the operating temperature is 40-50°C;

[0040] c. Unadsorbed CO 2 and part N 2 Discharged from the top of the adsorption tower, if the emission limit is less than 120mg / m3 st...

Embodiment 2

[0051] On the basis of the full temperature range pressure swing adsorption (FTrPSA) method for recovering hydrocarbons from the low-temperature methanol tail gas described in Example 1, the raw gas composition and treatment capacity at normal pressure remain unchanged, and the temperature is 80-100°C, the fan adjusts the pressure to 60-70KPa, and enters the hydrocarbon adsorption and concentration process, which is carried out in a PSA system composed of 12 adsorption towers with an operating temperature of 80-100°C, an adsorption pressure of 60-70KPa, and 12 adsorption towers. The adsorption towers are connected in parallel with each other, the operating temperature is maintained in the range of 80-100°C, the operating pressure during adsorption is 60-70KPa, and the 12 adsorption towers are operated alternately to ensure that the raw material gas enters continuously. There are always 1-11 adsorption towers at The other adsorption towers are in the regeneration state.

[0052...

Embodiment 3

[0054] On the basis of the full temperature range pressure swing adsorption (FTrPSA) method for recovering hydrocarbons from the low-temperature methanol tail gas described in Example 1, the raw gas composition and treatment capacity at normal pressure remain unchanged, and the temperature is 140-150°C, the fan adjusts the pressure to 90-100KPa, and enters the hydrocarbon adsorption and concentration process, which is carried out in a PSA system consisting of an operating temperature of 140-150°C, an adsorption pressure of 90-100KPa, and 12 adsorption towers. The adsorption towers are connected in parallel with each other, the operating temperature is maintained in the range of 140-150°C, the operating pressure during adsorption is 90-100KPa, and the 12 adsorption towers are operated alternately to ensure that the raw material gas enters continuously. There are always 1-11 adsorption towers in the The other adsorption towers are in the regeneration state.

[0055] In this exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com