Nano-photocatalyst and preparation method thereof

A nano-photocatalyst and nano-crystal technology, applied in the field of air purification, can solve the problems of small contact area, weak purification effect, and low purification efficiency of the substrate, and achieve the effect of increasing the direct contact area and improving the purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

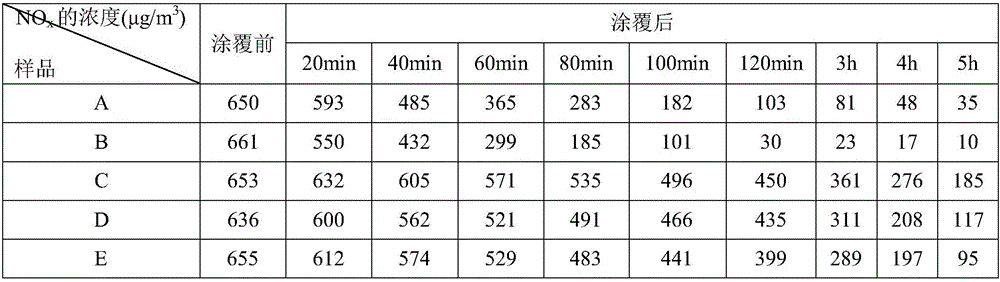

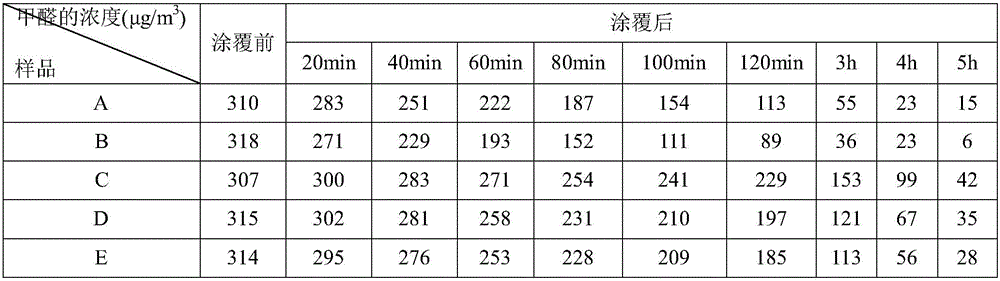

Examples

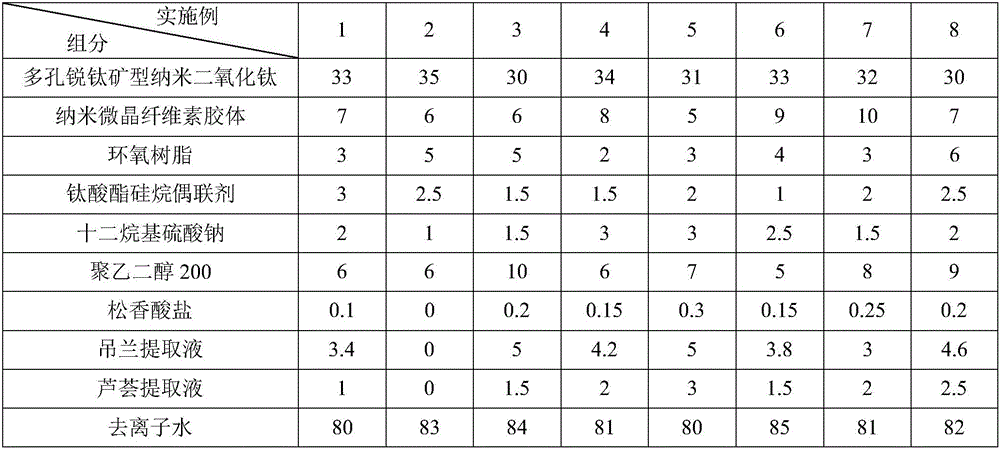

Embodiment 1-8

[0057] S1, pretreatment: Prepare porous anatase nano-titanium dioxide, polyethylene glycol 200, rosinate, sodium lauryl sulfate and deionized water according to the formula, mix with each other, and ultrasonically treat for 30 minutes;

[0058] S2, Preparation of film-forming agent: Prepare nano-microcrystalline cellulose colloid, epoxy resin and titanate silane coupling agent according to the formula, mix with each other, and disperse in a horizontal sander at high speed for 20-40min at a speed of 1500-2000r / min;

[0059] S3, preparation of dispersed emulsion: mix the pretreated product in S1 with the mixture in S2, and then disperse at a high speed for 0.5-1.5 hours in a horizontal sander at a speed of 3000-5000r / min;

[0060] S4, preparation of mixed extracts: prepare parts of spider plant extract, aloe extract and deionized water respectively according to the formula, and fully stir and mix;

[0061] S5, final product preparation: add the mixed extract obtained from S4 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com