A preparation method of nano-α-zirconium phosphate-supported graphene oxide flame retardant

A technology of zirconium phosphate and graphene, applied in the direction of chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of reducing flame retardant efficiency, poor thermal oxidation stability, weakening physical barriers, etc., to improve flame retardant efficiency, Low cost, enhanced physical barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

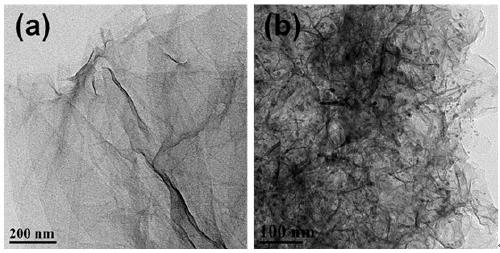

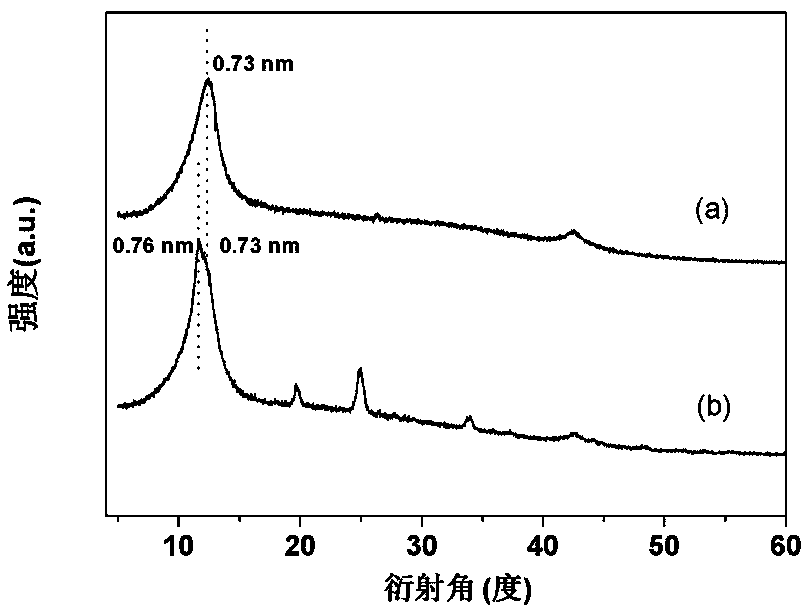

[0025] The preparation scheme of nano-α-zirconium phosphate supported graphene oxide (Zrp / GO) flame retardant is as follows: the present invention synthesizes graphene oxide by Hummers method, is about 2 g graphite and 2 g NaNO 3 into a three-necked flask, and then slowly add 80 ml H under an ice-water bath 2 SO 4 , after low-temperature intercalation oxidation for 2 h, slowly add 10 g potassium permanganate, then stir at 35 °C for 2 h, then slowly add 5% H 2 SO 4 Solution 200 ml (red), react at 60°C for 2 h after addition, then add a certain amount of H 2 o 2 React at 90°C for 1 h, and finally add 1 L of distilled water to continue the reaction for 1 h, the system is golden yellow, then centrifuge the obtained graphene oxide with 5% HCl and distilled water until the sulfuric acid in the graphene oxide is washed away root ions, dried, and then disperse graphene oxide in deionized aqueous solution to obtain a solution of graphene oxide (3 mg / ml).

[0026] 1 g zirconium oxy...

Embodiment 2

[0028] 0.5 g zirconium oxychloride (ZrOCl 2 ·8H 2 O) Dissolve in 6 ml of deionized water, then slowly add 12 ml of 85% phosphoric acid to obtain a precursor solution of α-zirconium phosphate, then add 90 ml of a solution with a concentration of 3 mg / ml graphene oxide, and then stir at 100 °C Reflux for 24 h, wash, and dry to obtain a nano-α-zirconium phosphate-supported graphene oxide flame retardant. The preparation of graphene oxide is the same as in Example 1.

Embodiment 3

[0030] 1 g zirconium oxychloride (ZrOCl 2 ·8H 2 O) Dissolved in 6 ml of deionized water, then slowly added 12 ml of 85% phosphoric acid to obtain a precursor solution of α-zirconium phosphate, then added 90 ml of a solution with a concentration of 3 mg / ml graphene oxide, and then heated at 90 ° C Stir and reflux for 30 h, wash, and dry to obtain a nano-α-zirconium phosphate-supported graphene oxide flame retardant. The preparation of graphene oxide is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com