Spray-free scratch-resistant high polymer material for automobile exterior parts and preparation method of spray-free scratch-resistant high polymer material

A technology of polymer materials and exterior decoration parts, which is applied in the field of spray-free anti-scratch polymer materials for automobile exterior decoration parts and its preparation. It can solve the problems of resource waste, precipitation, sticky and frosty surfaces, etc., and achieve impact resistance Good performance, improved scratch resistance, excellent scratch resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

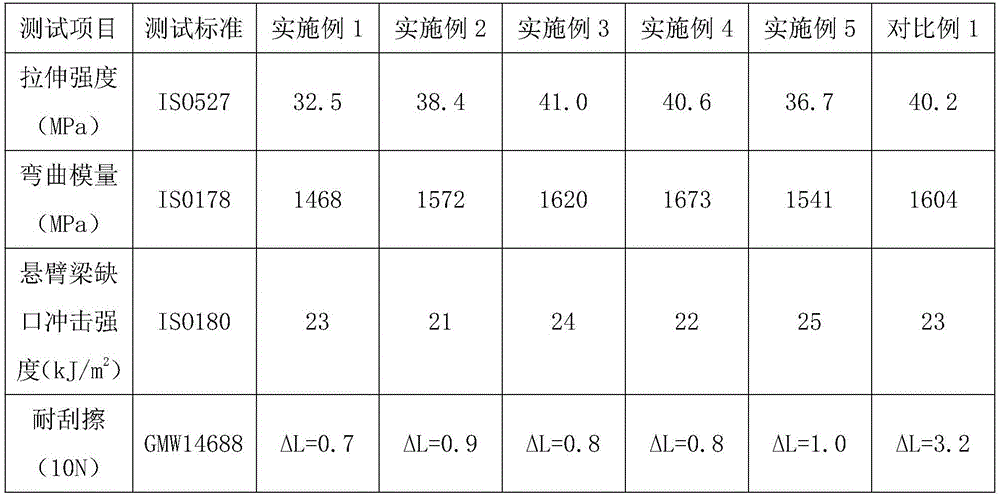

Examples

Embodiment 1

[0027] The spray-free anti-scratch polymer material for automotive exterior parts of the embodiment 1 of the present invention is composed of the following raw materials in parts by weight: 1.0 parts of amide polymer PA467, 34.8 parts of acrylate polymer, 2.5 parts of compatibilizer 10 parts of talcum powder, 6.3 parts of aluminum powder, 0.5 parts of antioxidant, 0.1 part of light stabilizer, 0.3 part of anti-scratch agent;

[0028] Among them, the anti-scratch agent in the above-mentioned embodiment 1 is formed by blending fully vulcanized styrene-butadiene rubber powder and polysiloxane polymer according to the weight ratio of 1:0.5; the acrylate polymer is polyethyl acrylate; The compatibilizer is maleic anhydride grafted polyolefin polymer; the antioxidant is blended with antioxidant 1010 and antioxidant DLTP at a weight ratio of 1:2; the light stabilizer is light stabilizer 770.

[0029] The preparation method of the spray-free anti-scratch polymer material for automobil...

Embodiment 2

[0035] The spray-free anti-scratch polymer material for automotive exterior parts of the embodiment 2 of the present invention is composed of the following raw materials in parts by weight: 3.6 parts of amide polymer PA468, 39.2 parts of acrylate polymer, and 3.8 parts of compatibilizer 20 parts of calcium carbonate, 9.0 parts of zinc powder, 2.5 parts of antioxidant, 0.5 part of light stabilizer, 0.7 part of anti-scratch agent;

[0036] Among them, the anti-scratch agent in the above-mentioned embodiment 2 is formed by blending fully vulcanized styrene-butadiene rubber powder and polysiloxane polymer at a weight ratio of 1:0.8; the acrylate polymer is polyethyl acrylate; The agent is maleic anhydride grafted polyolefin polymer; the antioxidant is blended by antioxidant 1010 and antioxidant DLTP according to the weight ratio of 1:2; the light stabilizer is light stabilizer 770.

[0037] The preparation method of the spray-free anti-scratch polymer material for automobile exter...

Embodiment 3

[0043] The spray-free anti-scratch polymer material for automotive exterior parts of the embodiment 3 of the present invention is composed of the following raw materials in parts by weight: amide polymer PA61076.5 parts, acrylate polymer 37.2 parts, compatibilizer 3.2 parts 15 parts of calcium carbonate, 7.5 parts of copper zinc powder, 1.3 parts of antioxidant, 0.2 part of light stabilizer, 0.5 part of anti-scratch agent;

[0044] Among them, the anti-scratch agent in the above-mentioned embodiment 3 is formed by blending fully vulcanized styrene-butadiene rubber powder and polysiloxane polymer according to the weight ratio of 1:0.6; the acrylate polymer is polyethyl acrylate; The agent is maleic anhydride grafted polyolefin polymer; the antioxidant is blended by antioxidant 1010 and antioxidant DLTP according to the weight ratio of 1:2; the light stabilizer is light stabilizer 770.

[0045] The preparation method of the spray-free anti-scratch polymer material for automobile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com