Preparation method of silver metal oxide electrical contact material

A technology of oxide electrical and contact materials, applied in the field of low-voltage electrical contact materials, can solve the problems that AgMeO electrical contact materials are not as good as possible, not suitable for mass production line production, and the contact size is not accurate enough. Market prospects, reducing labor intensity and labor costs, and the effect of uniform organizational structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

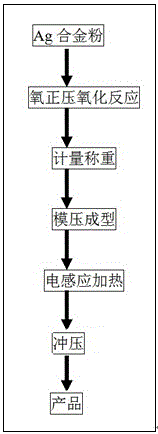

[0023] Such as figure 1 According to the process flow, the AgZn alloy powder with a particle size of 2000nm (containing 9.87% Zn, mass percentage) is oxidized in a self-made oxygen positive pressure oxidation furnace under the conditions of a positive oxygen pressure of 2 standard atmospheres, a temperature of 300 ° C, and a heat preservation of 20 hours. Oxidation reaction was carried out in the medium to obtain AgZnO powder with a ZnO content of 12% (mass percentage); after weighing, put them into square molds respectively, and perform compression molding to obtain AgZnO biscuits (pressing temperature was 100°C and pressing pressure was 500MPa); Then the blank is heated by electric induction. When the temperature reaches 900°C, it is stamped under the stamping pressure of 300MPa to obtain the finished product of AgZnO electrical contact material with a ZnO content of 12% (mass percentage).

Embodiment 2

[0025] Such as figure 1 The process flow is to oxidize the AgSn alloy powder with a particle size of 1000nm (containing 8.05% Sn, mass percentage) under the condition of a positive oxygen pressure of 3 standard atmospheres, a temperature of 600 ° C, and a temperature of 15 hours. Oxidation reaction in the furnace to obtain SnO 2 AgSnO with a content of 10% (mass percentage) 2 powder. After measuring and weighing, put them into square molds respectively, and perform compression molding to obtain AgSnO 2 Bisque (pressing temperature is 600°C, pressing pressure is 200MPa). Then the biscuit is heated by electric induction. When the temperature reaches 700°C, it is stamped under the stamping pressure of 900MPa to obtain SnO 2 AgSnO with a content of 10% (mass percentage) 2 finished electrical contact material.

Embodiment 3

[0027] Such as figure 1 According to the technological process, the AgSnCu alloy powder with a particle size of 700nm (containing 6.52% Sn, containing 6.61% Cu, mass percentage) is used under the condition of positive oxygen pressure of 4 standard atmospheres, temperature of 400 ° C, and heat preservation for 5 hours. Oxidation reaction was carried out in a self-made oxygen positive pressure oxidation furnace to obtain 2 AgSnO with 8 mass percent and 8 mass percent CuO 2 CuO powder. After measuring and weighing, put them into circular molds respectively, and carry out compression molding to obtain AgSnO 2 CuO biscuit (pressing temperature is 500°C, pressing pressure is 600MPa). Then the green body is heated by electric induction. When the temperature reaches 850°C, it is stamped under the condition of stamping pressure of 600MPa to obtain SnO 2 and AgSnO with CuO content of 8% and 8% (mass percent), respectively 2 Finished CuO electrical contact material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com