Layer stripping method in chip failure analysis process

A failure analysis and chip technology, applied in the preparation of test samples, etc., can solve the problems of difficult to control the peeling precision, short service life, limited processing area, etc., to improve the peeling efficiency, expand the processing range, and operate high control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The layer stripping method in the chip failure analysis process of the present invention will be further described in detail below in conjunction with specific embodiments.

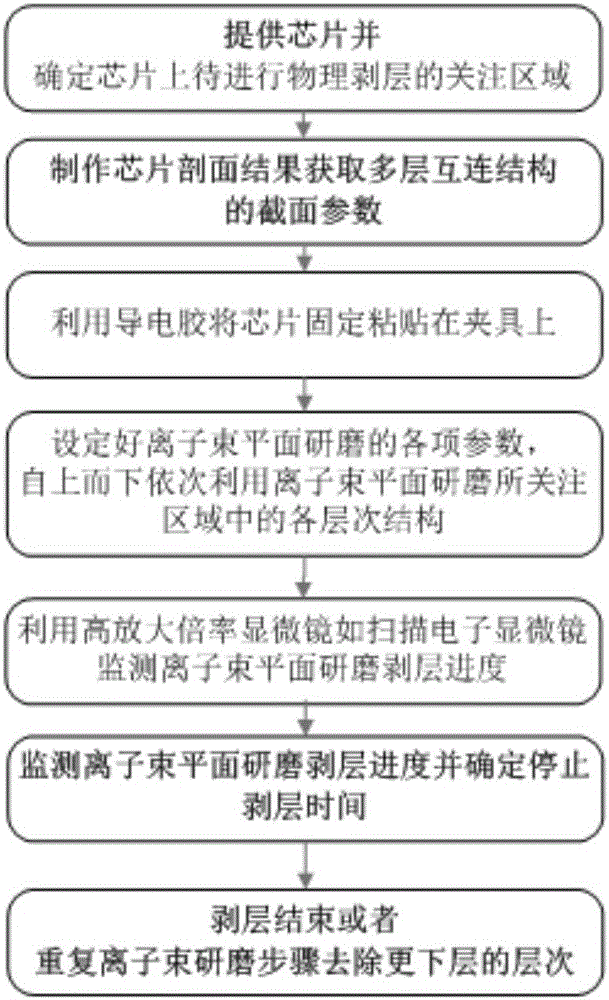

[0034] In this embodiment, a method for stripping layers in the chip failure analysis process, the flow chart is shown in figure 1 , including the following steps:

[0035] Step 1: Provide the chip to be analyzed, the chip includes the passivation layer on the Nth metal layer, the Nth metal layer, the oxide layer on the N-1th metal layer, the N-1th metal layer prepared from top to bottom on the substrate Metal layer, oxide layer on metal layer N-2 ... second metal layer, first metal layer, tantalum nitride diffusion barrier layer below first metal layer, where N = 6, determines on-chip target analysis layer, and select the area to be analyzed on the target analysis layer;

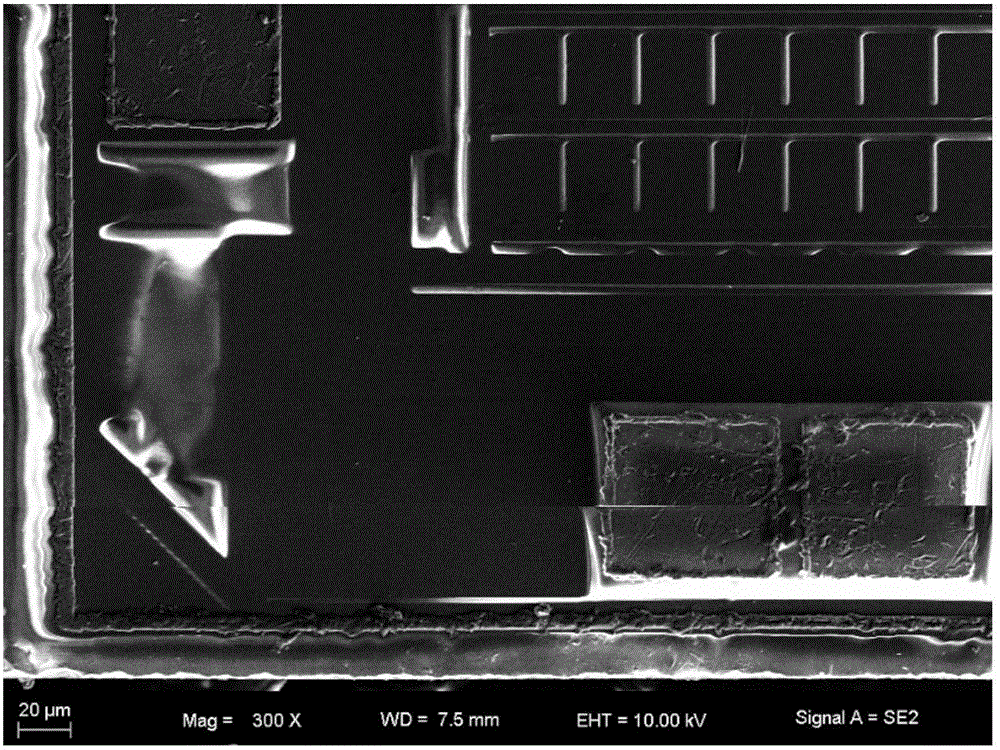

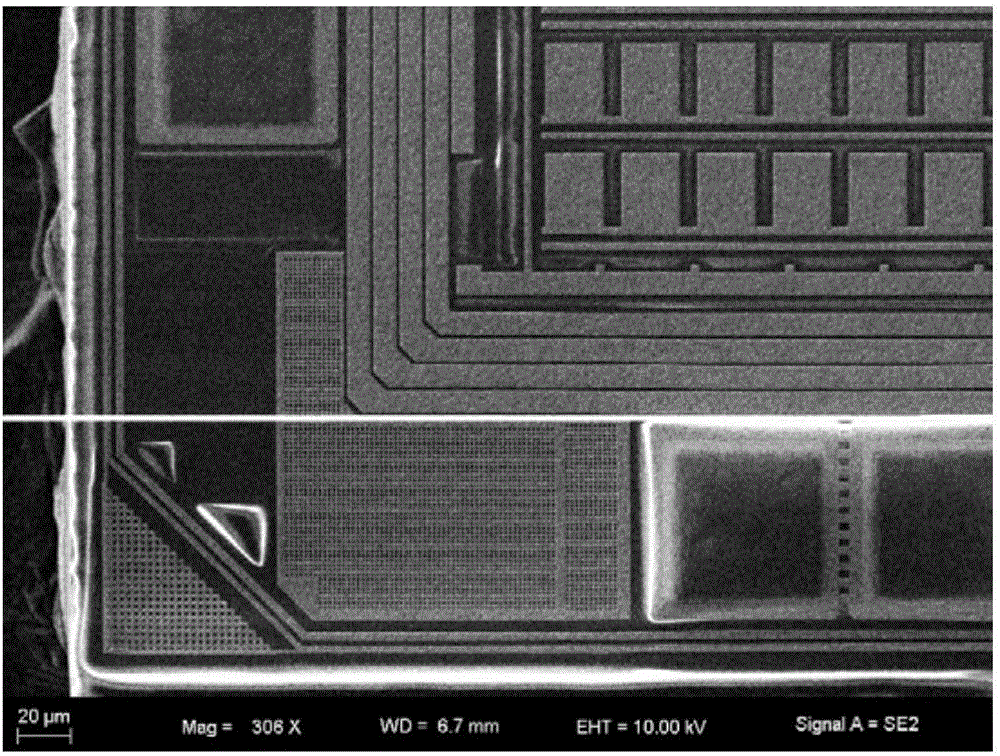

[0036] Step 2: Take another chip from the same batch as the above chip to be analyzed as a reference chip, use ion beam cutt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com