Light emitting diode and preparation method of light emitting diode

A technology of light-emitting diodes and light-emitting layers, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of limited performance improvement of LED chips and small performance effects of LED chips, and achieve the effect of improving luminous brightness and increasing electron injection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manner of the present invention will be described in detail below with reference to the drawings and embodiments.

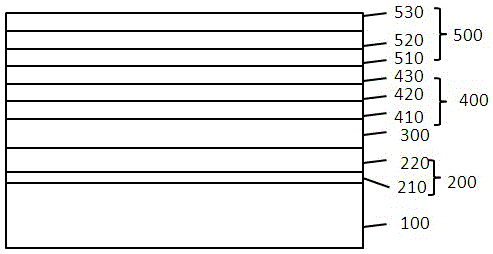

[0039] See attached figure 1 , a light-emitting diode from bottom to top: substrate 100, buffer layer 200, N-type semiconductor layer 300, quantum well layer 400, P-type semiconductor layer 500, wherein, P-type semiconductor layer 500 includes a first P-type semiconductor layer 510 , an electron blocking layer 520 and a second P-type semiconductor layer 530 ; the quantum well layer 400 is composed of a defect layer 410 , a repair layer 420 and a light emitting layer 430 . The defect layer 410 is formed by circular lamination of an InGaN well layer and a GaN barrier layer having an In / Ga content ratio C1 of 50% to 80%. The repair layer 420 is formed by cyclic lamination of InGaN well layers and GaN barrier layers with an In / Ga content ratio C2 of 45% to 60%. The thickness of each cycle of the repair layer 420 is greater than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com