Method for preparing walnut green husk polyphenol from fresh walnut green husks

A technology of walnut green husk and fresh walnut, which is applied in the field of preparation of walnut green husk polyphenols, can solve the problems of unfavorable natural drying, high drying and extraction temperature, and heat consumption, and achieve the effects of avoiding adverse effects, low preparation temperature, and reducing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

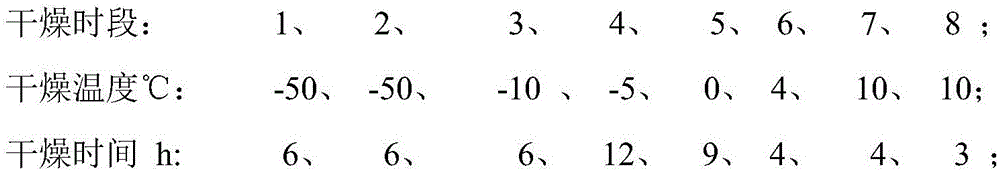

[0034] Fresh walnuts are peeled off fresh walnut green skins, and fresh walnut green skins are squeezed with a juicer. The juice is centrifuged at 3000 rpm for 20 minutes, and then the upper liquid and the lower residue are separated. The pH value of the upper liquid is adjusted to 3 and mixed. The polyphenol concentration of the sample solution is 2mg / mL, the sample volume is 1.6BV, and the sample flow rate is 2BV / h. Add it into a chromatography column with 1000 grams of AB-8 resin inside, add water to the chromatography column, and wash with water After the liquid flowing out from the bottom of the chromatography column is colorless, elute the chromatography column with ethanol with a volume fraction of 65%, the elution flow rate is 1BV / h, and the elution volume is 2.10BV, and the eluted liquid flowing out from the bottom of the chromatography column is collected. solution, the eluate was concentrated in vacuum to a solid solution content of 52% of the solution at a vacuum de...

Embodiment 2

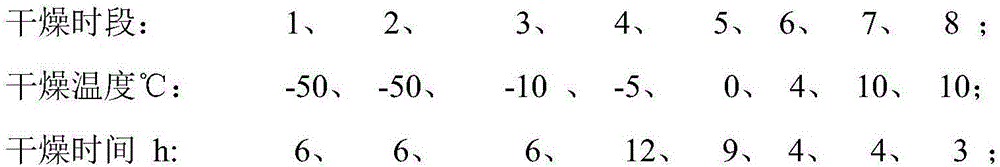

[0038] Fresh walnuts are peeled off fresh walnut green skins, fresh walnut green skins are squeezed with a juicer, the juice is centrifuged at 4500 rpm for 10 minutes, and then the upper liquid and the lower residue are separated, the pH value of the upper liquid is adjusted to 4, and the above The polyphenol concentration of the sample liquid is 3mg / mL, the sample volume is 1.6BV, and the sample flow rate is 2BV / h, and it is added to the chromatographic column containing 2000 grams of AB-8 resin, and water is added to the chromatographic column, and washed with water After the liquid flowing out from the bottom of the chromatography column is colorless, elute the chromatography column with ethanol with a volume fraction of 70%, the elution flow rate is 2BV / h, and the elution volume is 2.10BV, and the eluted liquid flowing out from the bottom of the chromatography column is collected. solution, the eluate was vacuum-concentrated to a solid solution content of 54% of the solutio...

Embodiment 3

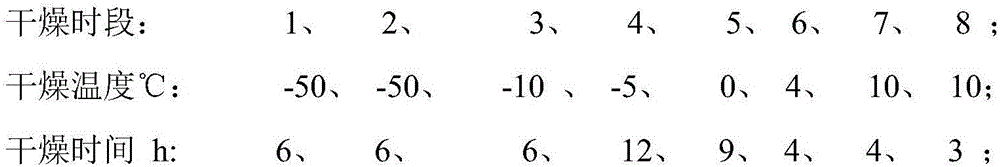

[0042] Fresh walnuts are peeled and fresh walnut green skins are extracted, fresh walnut green skins are squeezed with a juicer, the juice is centrifuged at 4000 rpm for 15 minutes, and then the upper liquid and the bottom residue are separated, the pH value of the upper liquid is adjusted to 3.6, and the above The polyphenol concentration of the sample liquid is 2.5mg / mL, the sample volume is 1.6BV, and the sample flow rate is 2BV / h, and it is added to a chromatographic column with 1500 grams of AB-8 resin inside, and water is added to the chromatographic column. After washing until the liquid flowing out from the bottom of the chromatography column is colorless, elute the chromatography column with ethanol with a volume fraction of 75%, the elution flow rate is 1-2BV / h, and the elution volume is 2.10BV, and collect the liquid flowing out from the bottom of the chromatography column The eluate, the eluate was vacuum-concentrated to a solid solution content of 55% of the soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com