In-situ remediation method for mining area watershed heavy metal pollution bottom sludge

A technology of polluted sediment and in-situ remediation, which is applied in sludge detoxification, sludge treatment, biological sludge treatment, etc., can solve the problems of affecting the longevity of ecological restoration, poor stability of plant communities, and limitation of vegetation growth and development. To achieve the effect of helping plants absorb and enrich heavy metals, help plants grow and stabilize slopes, and prevent soil erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

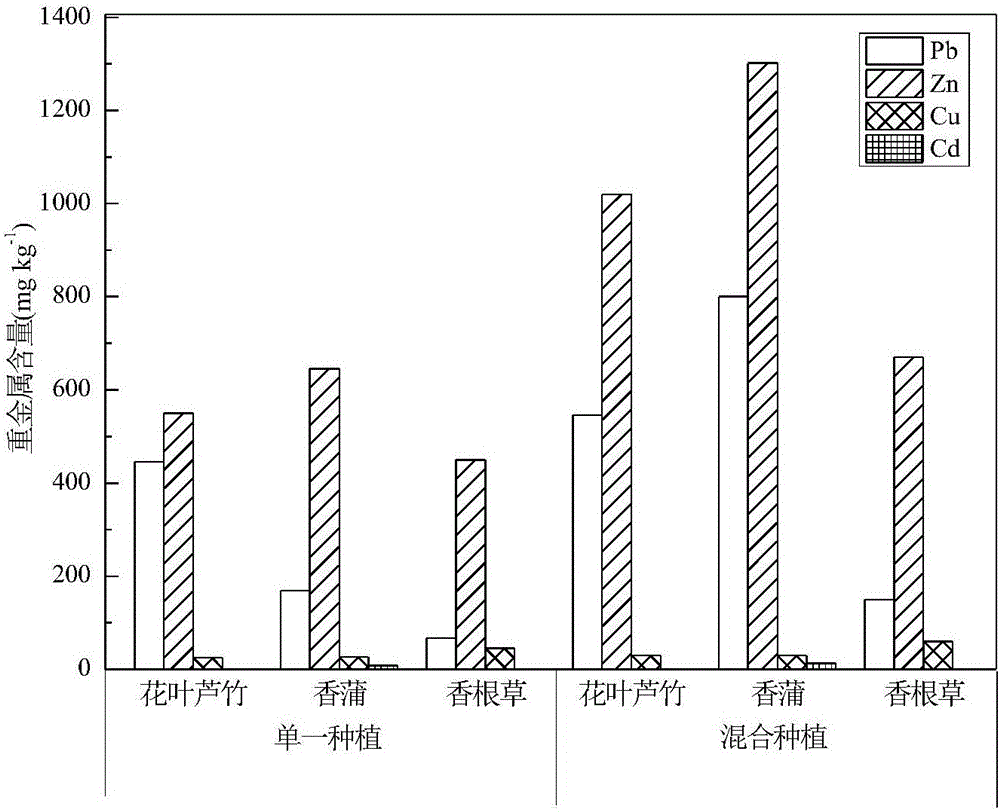

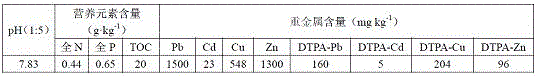

[0027] The heavy metal polluted bottom mud of a mining area was collected in the field, air-dried, sieved, and divided into large and medium stones, small stones, silt and fine sand, and the bottom mud to be repaired was obtained after the mud was passed through a 2mm sieve, and the basic properties of the bottom mud were analyzed. The results are shown in Table 1. Bottom sludge heavy metal solidification test: Add heavy metal stabilizer as described in patent CN105062495A to the bottom sludge to be repaired at a mass fraction of 2%, stir evenly, keep the water content at 90%, maintain it for 15 days, and take samples. The content of available heavy metals in sediment was determined by DTPA extraction ICP-OES.

[0028] Table 1 Basic properties of heavy metal-polluted sediment in a mining area watershed

[0029]

[0030] It has been determined that after 15 days of stability with the addition of reagents, the content of effective heavy metals in the DTPA leached sediment si...

Embodiment 2

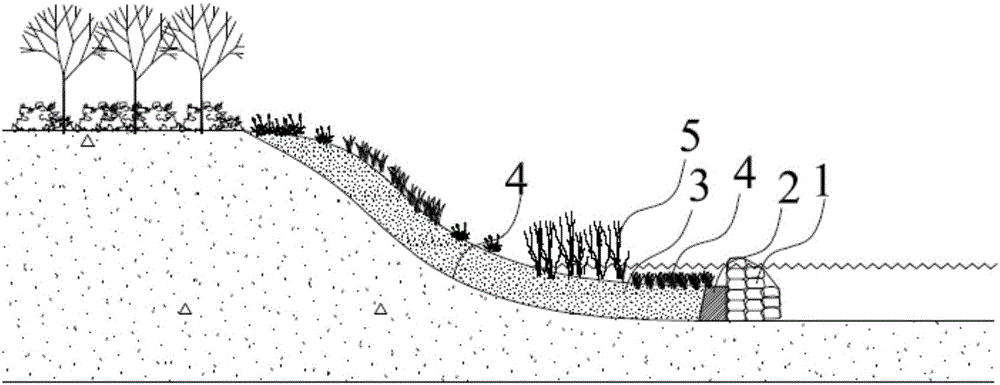

[0035] refer to figure 2 , in-situ remediation of heavy metal contaminated sediment of the present invention was carried out in the middle reaches of a river in a mining area of Suxian District, Chenzhou City, Hunan Province. In the in-situ restoration of heavy metal-contaminated sediment in this embodiment, first select a 100-meter-long river section with a slope below 35°, and screen the river sediment into large and medium stones, pebbles, silt and fine sand. Make full use of large and medium stones to pile up and fix with barbed wire to form a slope protection wall 1, and the height of the slope protection wall 1 is higher than the normal water level by more than 50cm. The slope protection wall 1 is built by using the original stones in the bottom mud to make full use of the existing resources and reduce the cost. On the side close to the slope protection wall 1 near the bank, an impermeable barrier layer 2 is provided with clay for filling the pores of the slope prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com