Heat preservation building material and preparation technology

A technology of building materials and heavy calcium powder, which is applied in the field of building materials, and can solve unsatisfactory properties such as bond strength, water resistance and alkali resistance, freeze-thaw resistance and construction, increase the adhesion of surface coatings, ceramic tiles, wallpapers, and fall off And other problems, to achieve good anti-sag performance, good storage stability, good water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

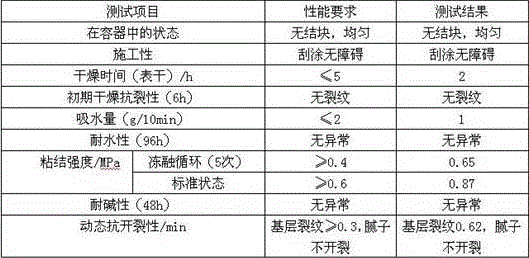

Image

Examples

Embodiment 1

[0033] Example 1 A thermal insulation building material prepared from the following main raw materials in parts by weight (each part is 2kg): 92 parts of heavy calcium powder, 10 parts of calcium lignosulfonate, 28 parts of talcum powder, 10 parts of water glass, 5 parts of aluminum hydroxide, 8 parts of water-soluble resin, 9 parts of green tea, 3 parts of borax, 5 parts of zinc borate, 6 parts of sodium alginate.

[0034] The preparation method of above-mentioned insulation building material is:

[0035] (1) Take 1 / 2 of the total weight of heavy calcium powder and 1 / 2 of the total weight of talcum powder, put them into a blender, and stir evenly;

[0036] (2) Put the green tea into the dryer, the air inlet temperature of the dryer is 115°C, the leaf thickness is 1.2cm, the time is 15 minutes, take it out, spread it for 2 hours, grind it into fine powder, and sieve;

[0037] (3) Add the product obtained in step (2), calcium lignosulfonate, water glass, water-soluble resin an...

Embodiment 2

[0040] Example 2 A thermal insulation building material prepared from the following main raw materials in parts by weight (each part is 2kg): 105 parts of heavy calcium powder, 20 parts of calcium lignosulfonate, 36 parts of talcum powder, 16 parts of water glass, 10 parts of aluminum hydroxide, 13 parts of water-soluble resin, 15 parts of green tea, 7 parts of borax, 11 parts of zinc borate, 12 parts of sodium alginate.

[0041] The preparation method of above-mentioned insulation building material is:

[0042] (1) Take 1 / 2 of the total weight of heavy calcium powder and 1 / 2 of the total weight of talcum powder, put them into a blender, and stir evenly;

[0043] (2) Put the green tea into the dryer, the air inlet temperature of the dryer is 150°C, the leaf thickness is 2.5cm, the time is 30 minutes, take it out, spread it for 2 hours, grind it into fine powder, and sieve;

[0044] (3) Add the product obtained in step (2), calcium lignosulfonate, water glass, water-soluble re...

Embodiment 3

[0046] Example 3 A thermal insulation building material prepared from the following main raw materials in parts by weight (each part is 2kg): 95 parts of heavy calcium powder, 13 parts of calcium lignosulfonate, 30 parts of talcum powder, 12 parts of water glass, 6 parts of aluminum hydroxide, 10 parts of water-soluble resin, 11 parts of green tea, 4 parts of borax, 6 parts of zinc borate, and 8 parts of sodium alginate.

[0047] The preparation method of above-mentioned insulation building material is:

[0048] (1) Take 1 / 2 of the total weight of heavy calcium powder and 1 / 2 of the total weight of talcum powder, put them into a blender, and stir evenly;

[0049] (2) Put the green tea into the dryer, the air inlet temperature of the dryer is 125°C, the leaf thickness is 1.5cm, the time is 18 minutes, take it out, spread it for 2 hours, grind it into fine powder, and sieve;

[0050] (3) Add the product obtained in step (2), calcium lignosulfonate, water glass, water-soluble re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com