Preparation method of low-carbon magnesia carbon brick

A carbon-magnesia-carbon brick and magnesia technology, which is applied in the field of preparation of low-carbon magnesia-carbon bricks, can solve the problems of reducing slag resistance and thermal shock resistance, and achieve high strength, low environmental pollution, and small gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

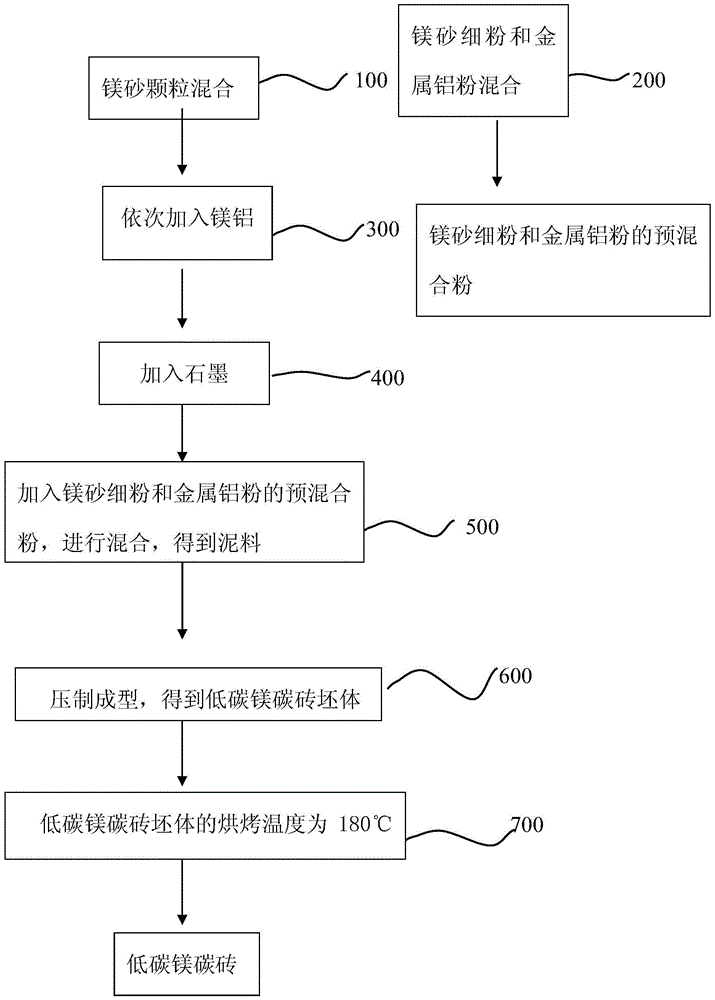

Method used

Image

Examples

Embodiment 1

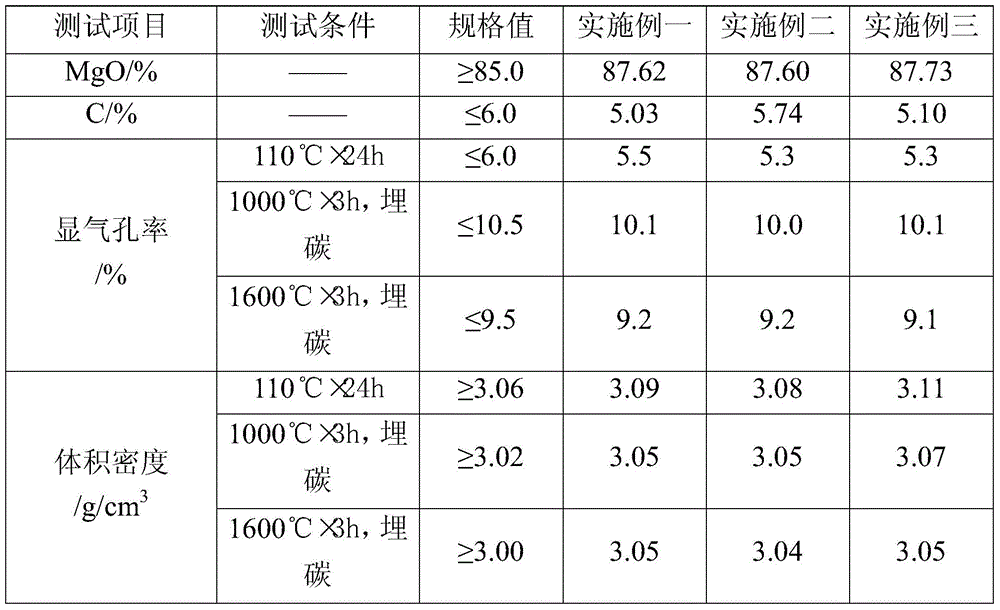

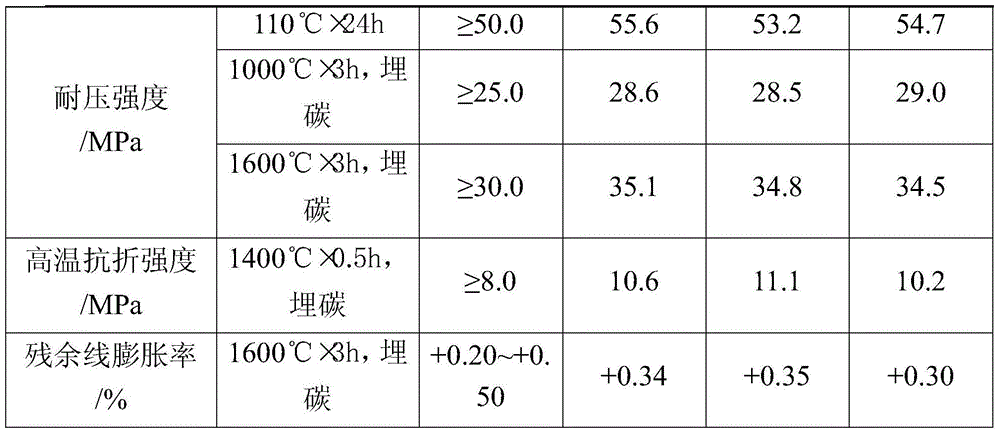

[0046] In this embodiment, the raw material composition (weight ratio) of the low-carbon magnesia-carbon brick is: 95 parts of magnesia; 3 parts of micronized graphite; 1 part of metal aluminum powder; 2 parts of magnesium-aluminum cement; 1 part of water, Its dosing and processing procedures are carried out according to the steps described above.

[0047] In this example, the particle size distribution of magnesia is: 8mm~5mm15wt%; 5mm~3mm25wt%; 3mm~1mm25wt%, 1mm~0.088mm15wt%, 0.088mm~0mm20wt%; the mass percentage of graphite is 98%, and the particle size gradation is: 5-15μm80wt%; the mass percentage of metal Al powder is 98%, and the particle size distribution is: 0.088mm-0mm80wt%; MgO and Al 2 o 3 The total mass percentage of the magnesia-carbon brick is 50% (that is, the weight loss on ignition of the magnesium-aluminum cement at 1050°C is 50%), and its particle size is 0.048mm to 0mm; the obtained low-carbon magnesia-carbon brick body is baked at 180°C Bake for 8 hours...

Embodiment 2

[0050] In this embodiment, the raw material composition (weight ratio) of the low-carbon magnesia-carbon brick is: 90 parts of magnesia; 8 parts of micronized graphite; 2 parts of metal aluminum powder; 4 parts of magnesium-aluminum cement; Its dosing and processing procedures are carried out according to the steps described above.

[0051] In this example, the magnesia particle size gradation is: 8mm~5mm1wt%; 5mm~3mm30wt%; 3mm~1mm35wt%, 1mm~0.088mm15wt%, 0.088mm~0mm19wt%; the mass percentage of graphite is 98%, and the particle size gradation is: 5-15μm90wt%; the mass percentage of metal Al powder is 98%, and the particle size distribution is: 0.088mm-0mm90wt%; MgO and Al 2 o 3 The total mass percentage is 50% (that is, the weight loss of magnesium-aluminum cement at 1050°C is 50%), and its particle size is 0.048mm-0mm; the obtained low-carbon magnesia-carbon brick body is baked at 200°C Bake for 10 hours.

[0052] The performance test results of the obtained low-carbon ma...

Embodiment 3

[0054] In this embodiment, the raw material composition (weight ratio) of the low-carbon magnesia-carbon brick is: 92 parts of magnesia; 5 parts of micronized graphite; 1 part of metal aluminum powder; 3 parts of magnesium-aluminum cement; 2 parts of water, Its dosing and processing procedures are carried out according to the steps described above.

[0055] In this example, the magnesia particle size gradation is: 8mm~5mm10wt%; 5mm~3mm20wt%; 3mm~1mm30wt%, 1mm~0.088mm25wt%, 0.088mm~0mm15wt%; the mass percentage of graphite is 98%, and the particle size gradation is: 5-15μm85wt%; the mass percentage of metal Al powder is 98%, and the particle size distribution is: 0.088mm-0mm85wt%; MgO and Al 2 o 3 The total mass percentage of the magnesia-carbon brick is 50% (that is, the weight loss on ignition of the magnesium-aluminum cement at 1050°C is 50%), and its particle size is 0.048mm to 0mm; the obtained low-carbon magnesia-carbon brick body is baked at 190°C Bake for 9 hours.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com