Device and method for preparing biodiesel by rapid reaction in rotating fixed bed

A biodiesel and fast-response technology, applied in biofuels, petroleum industry, fatty acid esterification, etc., can solve problems such as uneven heat and mass transfer, low esterification reaction rate, untimely product separation, etc., and achieve easy manufacturing , save investment costs, good effect of reaction and mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

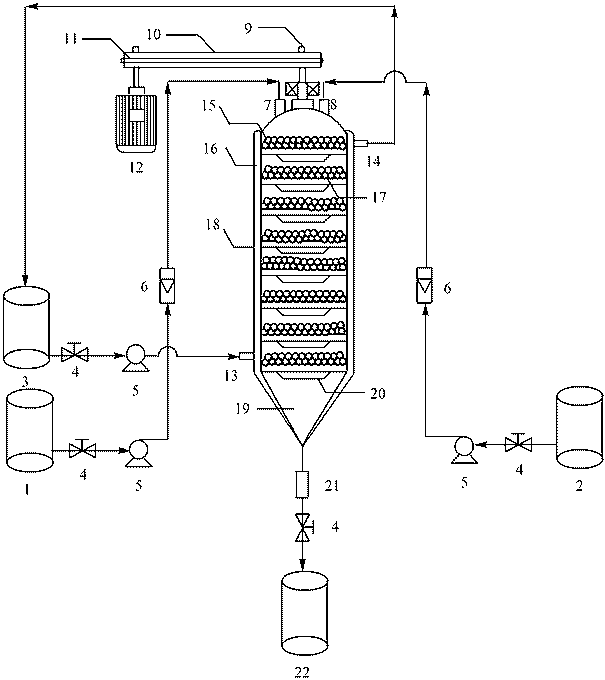

[0036] according to figure 1Connect the various parts, and the raw oil is acidified oil with an acid value of 137.23 mgKOH / g. The acidified oil is pretreated before use, first filtered to remove impurities inside, and then rotary steamed to remove water. Methanol is first passed into a 500 mL fixed-bed reactor equipped with a cation exchange resin catalyst, which reaches about 80% of the volume of the reactor. 65 o C circulating hot water through the jacket to heat the reaction, and at the same time turn on the rotating device at a speed of 1000 r / min. The acidified oil was passed into the rotating fixed bed reactor at 5.0 mL / min. As the reaction progressed, observe the stratification of the lower cone product in time, and take samples every 10 min. Sample at 75 o Rotary steam for 15 minutes at C, then measure the acid value of the product according to GB / T 5530-2005 "Animal and Vegetable Fats and Fats - Determination of Acid Value and Acidity", and use formulas (1) and (...

example 2

[0040] according to figure 1 Connect the components, and select the raw oil as waste cooking oil with an acid value of 16.08 mgKOH / g. Waste cooking oil is pretreated before use, first filtered to remove impurities inside, and then rotary steamed to remove water. Methanol is first passed into a 1 L fixed-bed reactor equipped with a cation exchange resin catalyst, and passes to about 80% of the volume of the reactor. 65 o C circulates hot water through the jacket to heat the reaction, and at the same time turns on the rotating device at a speed of 3000 r / min. Waste cooking oil was passed into the rotating fixed bed reactor at 10.0 mL / min. As the reaction progressed, observe the stratification of the lower cone product in time, and take samples every 10 min. Sample at 75 o Rotary steam for 15 minutes at C, then measure the acid value of the product according to GB / T 5530-2005 "Animal and Vegetable Fats and Fats - Determination of Acid Value and Acidity", and use formulas (1)...

example 3

[0044] according to figure 1 Connect the parts, and the raw material oil is jatropha oil with an acid value of 36.10 mgKOH / g. Methanol is first passed into a 250 mL fixed-bed reactor equipped with a cation exchange resin catalyst, to about 80% of the volume of the reactor. 30 o C Circulating hot water passes through the jacket to heat the reaction, and at the same time, the rotating device is turned on at a speed of 600 r / min. Jatropha oil was passed into the rotating fixed-bed reactor at 2.0 mL / min. As the reaction progressed, observe the stratification of the lower cone product in time, and take samples every 10 min. Sample at 75 o Rotary steam at C for 15 minutes, then measure the acid value of the product according to GB / T 5530-2005 "Determination of Acid Value and Acidity of Animal and Vegetable Oils and Fats", and use formulas (1) and (2) to calculate the acid value and conversion rate. See Table 3 for specific data.

[0045] Table 3 Reaction temperature 30 o C, T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com