Non-enzyme glucose sensor and manufacturing method thereof

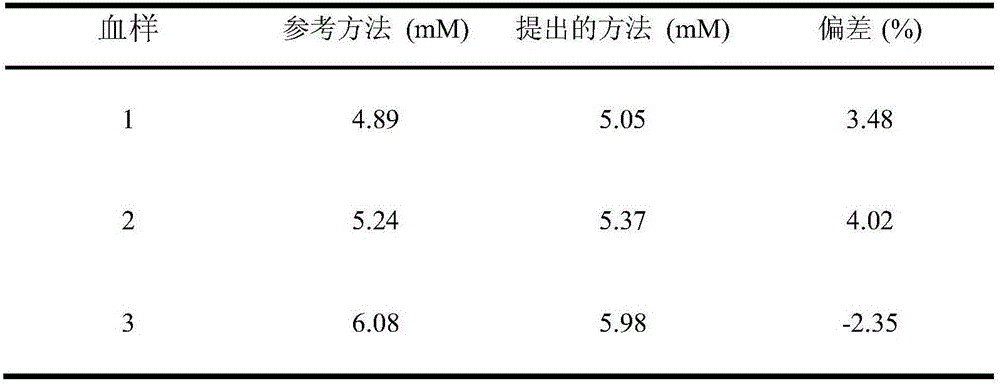

A glucose sensor and glassy carbon electrode technology, which is applied in the field of Pd-Ce-GC-based enzyme-free glucose sensor and its preparation, can solve the problems of insufficient sensitivity, insufficient composition and preparation process, and insufficient selectivity. High performance, high linear correlation, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

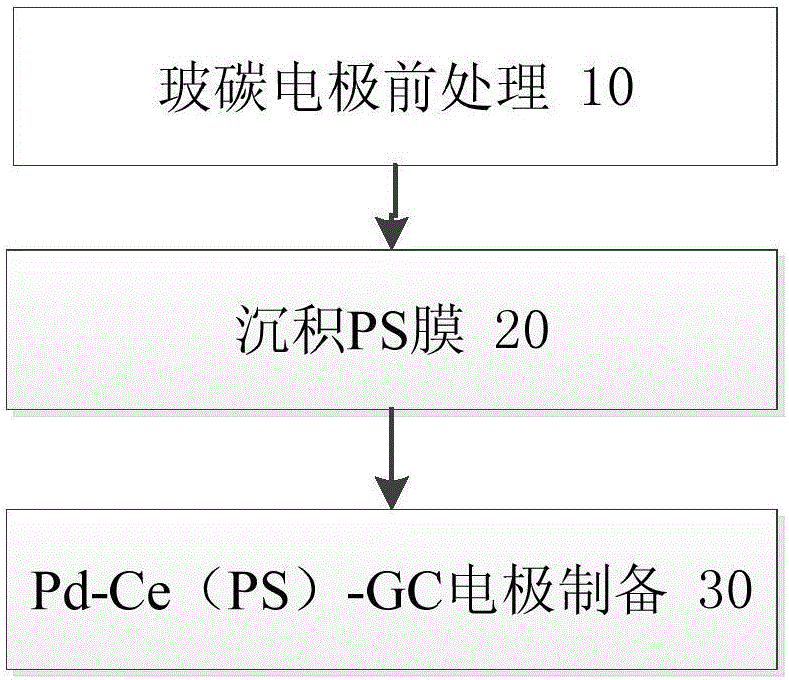

[0027] (1) Glassy carbon electrode pretreatment: Polish with 0.05μm alumina powder, rinse the polished electrode with deionized water to remove dirt, and then ultrasonically wash with 2mol / LNaOH, ethanol, 2mol / LHCl and deionized water .

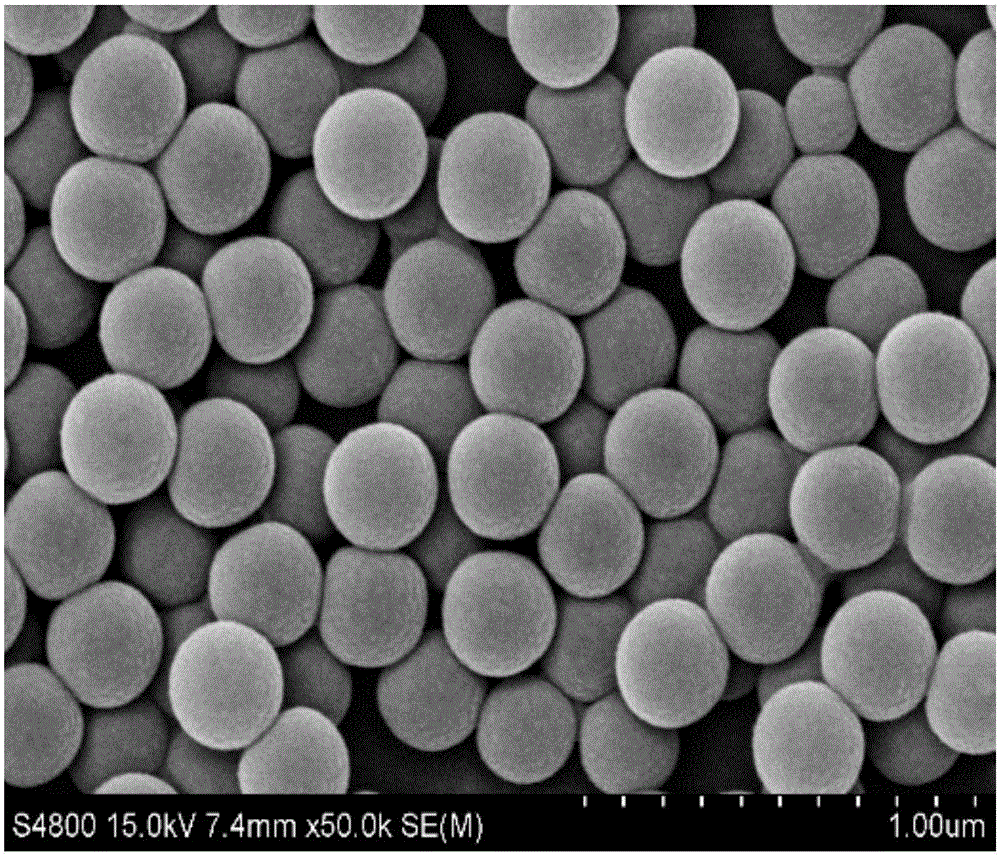

[0028] (2) Deposit PS film: Drop-coat 5 μL of PS bead aqueous solution (uniform by ultrasound) on the pretreated glassy carbon electrode, place it in the dark at room temperature for 24 hours, and then put it in a vacuum oven at 70°C for one hour. The SEM image of the glassy carbon electrode covered by the PS bead film is as follows figure 2 shown.

[0029] (3) Preparation of Pd-Ce(PS)-GC electrode: preparation containing 0.8mMPdCl 2 , 0.2mMCeCl 3 、0.5MKNO 3 Electrodeposition bottom solution. The electrode deposited with PS film was placed in the solution prepared above, and the electrochemical reduction experiment was carried out at -0.3V, and the deposition electricity was 1×10 -2 c. Pd in solution during this process 2+ 、Ce 3+ ...

Embodiment 2

[0033] (1) Glassy carbon electrode pretreatment: Polish with 0.05μm alumina powder, rinse the polished electrode with deionized water to remove dirt, and then ultrasonically wash with 2mol / LNaOH, ethanol, 2mol / LHCl and deionized water .

[0034] (2) Deposit PS film: Drop-coat 5 μL of PS bead aqueous solution (uniform by ultrasound) on the pretreated glassy carbon electrode, place it in the dark at room temperature for 24 hours, and then put it in a vacuum oven at 70°C for one hour.

[0035] (3) Preparation of Pd-Ce(PS)-GC electrode: preparation containing 0.8mMPdCl 2 , 0.2mMCeCl 3 、0.5MKNO 3 Electrodeposition bottom solution. The electrode deposited with PS film was placed in the above solution, and the electrochemical reduction experiment was carried out at -0.3V, and the deposition electricity was 1×10 -2 c. Pd in solution during this process 2+ 、Ce 3+ be reduced to form Pd-Ce nanoparticles. Put the glassy carbon electrode with adsorbed Pd-Ce particles into tetrahy...

Embodiment 3

[0039] (1) Pretreatment of matrix glassy carbon electrode: Polish with 0.05μm alumina powder, rinse the polished electrode with deionized water to remove dirt, and then pass through 2mol / LNaOH, ethanol, 2mol / LHCl and deionized water in sequence Ultrasonic washing.

[0040] (2) Preparation of PS template: Drop-coat 5 μL of PS bead aqueous solution (uniform by ultrasound) on the pretreated glassy carbon electrode, place it in the dark at room temperature for 24 hours, and then put it in a vacuum oven at 70°C for one hour .

[0041] (3) Preparation of Pd-Ce(PS)-GC electrode: preparation containing 0.8mMPdCl 2 , 0.2mMCeCl 3 、0.5MKNO 3 Electrodeposition bottom solution. The electrode deposited with PS film was placed in the solution prepared above, and the electrochemical reduction experiment was carried out at -0.3V, and the deposition electricity was 1×10 -2 c. Pd in solution during this process 2+ 、Ce 3+ be reduced to form Pd-Ce nanoparticles. Put the glassy carbon el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com