Formation method of semiconductor structure

A semiconductor and gas technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of holes and low density, and achieve the effect of improving density and preventing holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

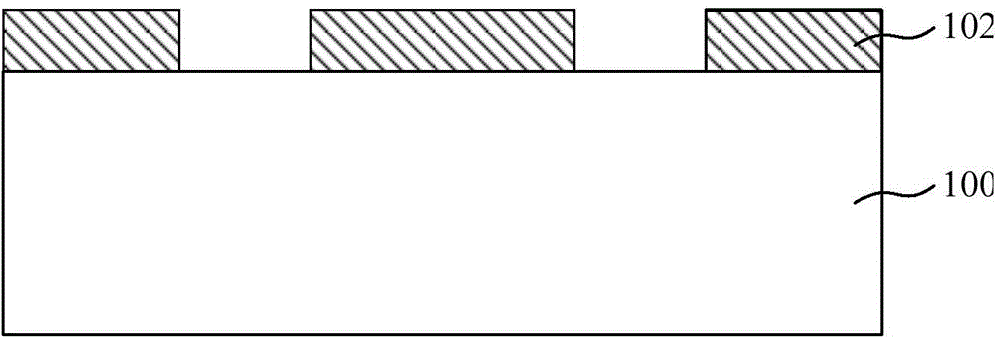

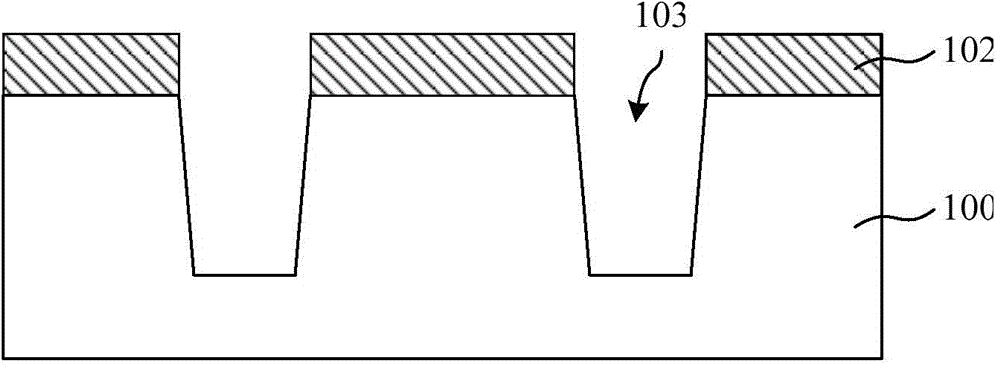

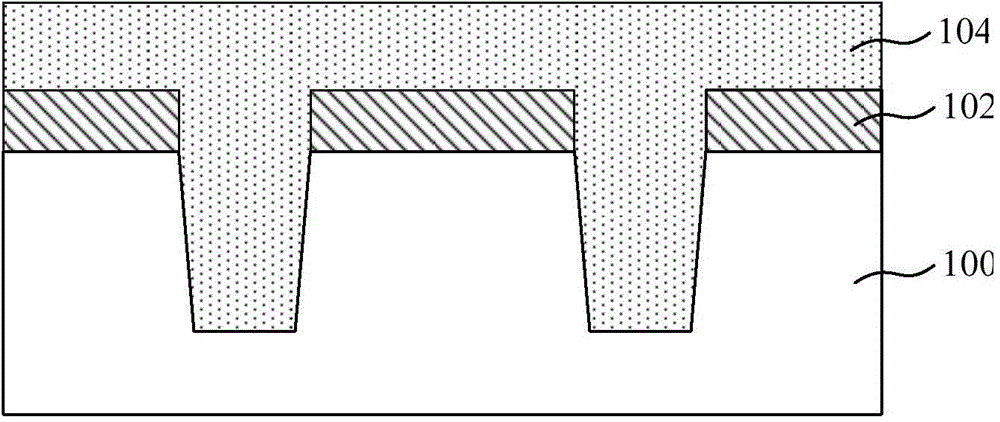

[0029] As mentioned in the background art, the shallow trench isolation structure formed in the prior art has the problems of low density and holes.

[0030] The study found that the middle area of the isolation material layer formed by the high aspect ratio deposition process has low density, so the middle area of the shallow trench isolation structure formed by the chemical mechanical polishing process on the isolation material layer is prone to holes or depressions, which affects the Electrical isolation performance of shallow trench isolation structures.

[0031] Further research found that the gas used in the high aspect ratio deposition process is TEOS (tetraethoxysilane, Si(OC 2 h 5 ) 4 ) and O 3 , when forming the isolation material layer, the reaction chamber maintains a certain chamber pressure and temperature, and TEOS and O 3 into the reaction chamber, TEOS and O 3 The reaction forms a silicon oxide isolation material layer. The isolation material layer is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com