Airborne Molecular Sieve Oxygen System

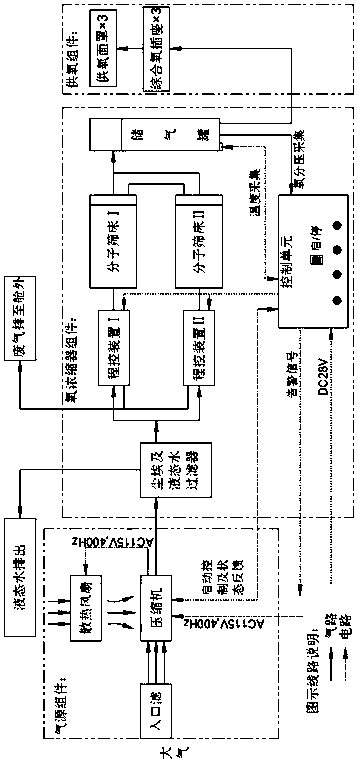

An oxygen system and molecular sieve technology, applied in the field of flight, can solve the problem of airborne products that cannot meet the requirements of high, low temperature, temperature shock resistance, damp heat, mold, salt spray acceleration, vibration, shock, temperature-humidity-high electromagnetic compatibility, Life, reliability, maintainability, testability, security, safety, strength, volume, and airtightness of the oxygen generator cannot meet the environmental requirements of military helicopters, the oxygen volume of the oxygen generator, and the output oxygen pressure cannot meet the high-altitude oxygen demand, etc. problems, to achieve the effect of compact structure design, convenient replacement and maintenance, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

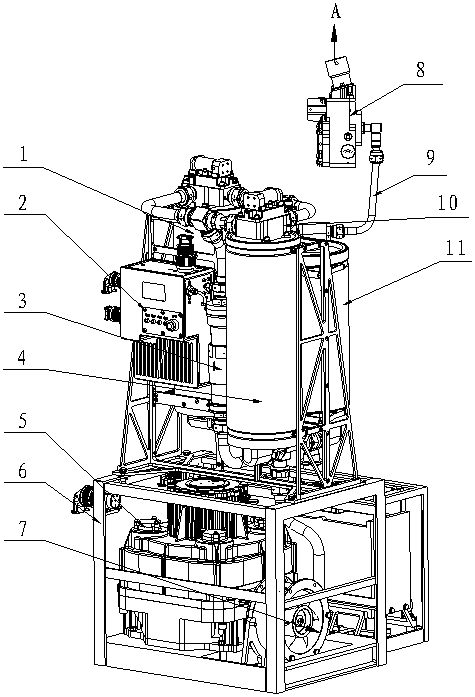

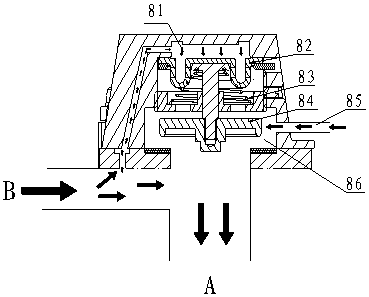

[0031] Such as figure 1 and figure 2 As shown, the present invention includes a gas source assembly, an oxygen concentrator and an oxygen supply assembly, the gas source assembly includes a scroll compressor 6, a cooling fan 7 and a filter 3, and the oxygen concentrator includes a control unit 2, a molecular sieve bed I1, and a molecular sieve bed II4 and a gas storage tank 11 with a pressure stabilizing structure, the oxygen supply components include an oxygen supply mask, an oxygen supply pipeline 9, an oxygen supply regulator 8 with an anti-suffocation valve structure and an oxygen flow self-adjusting structure, molecular sieve bed I1 and molecular sieve bed II4 is respectively provided with a program control device I and a program control device II, the air path output end of the scroll compressor 6 is connected to the air path input end of the filter 3, the air outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com