Compounding of carbon-4 fluoride surfactant and application of compound system preparation method of carbon-4 fluoride surfactant to aqueous film forming foam extinguishing agent

A technology of foam fire extinguishing agent and fluorocarbon surface, which is applied in the direction of fire prevention equipment, dissolution, chemical instruments and methods, etc. It can solve the problems of difficult to achieve foam performance, high foam stability, production difficulty and high cost, and achieve aqueous film-forming spreading Fast speed, good foaming performance and excellent surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

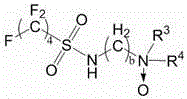

Method used

Image

Examples

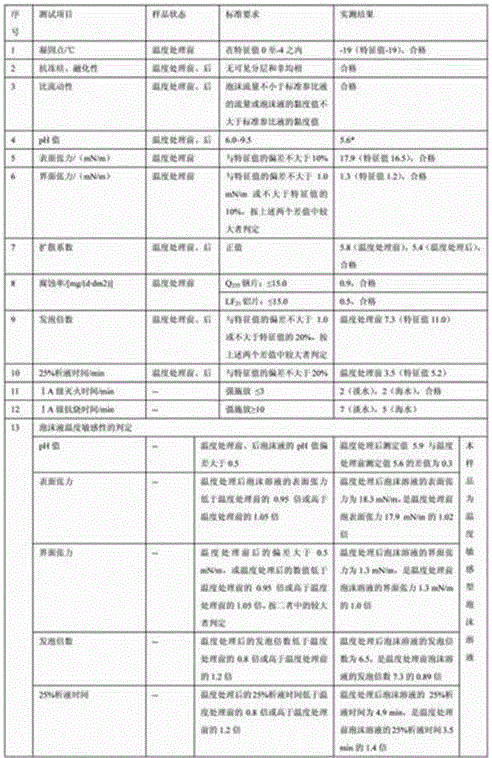

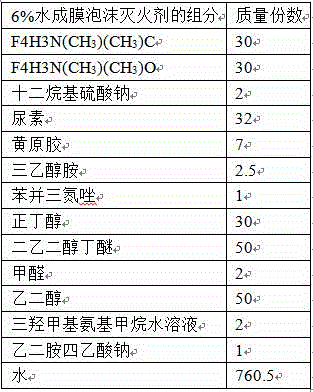

Embodiment 1

[0040] Add 224.4kg N,N-dimethyl-propylenediamine (2200 moles) and 404.0kg triethylamine (4000 moles) into a 2500L reactor with reflux, add 700L tetrahydrofuran, and stir evenly. Add 604.0kg perfluorobutylsulfonyl fluoride (2000 moles) to it, heat up to 80°C after all the addition, react for 8 hours, evaporate the solvent and excess amine under reduced pressure, wash with water, filter, and dry the filter residue to obtain C 4 f 9 SO 2 NH(CH 2 ) 3 N(CH 3 ) 2 702.0kg, yield 91.4%. 192kgC 4 f 9 SO 2 NH(CH 2 ) 3 N(CH 3 ) 2 (500 mol) in a 2500L reactor, add 200L of ethanol and stir to dissolve it, dissolve 60.6kg of sodium chloroacetate (520 mol) in 240.0kg of deionized water and add it to the reactor, stir and mix well and heat up to 80°C , reacted for 4 hours, and cooled. Ethanol was evaporated under reduced pressure, crystallized by cooling, filtered, and the filter residue was dried to obtain F4H3N(CH 3 )(CH 3 ) C203.6kg, yield 92.1%. Take 1.00kgF4H3N(CH 3 )(C...

Embodiment 2

[0042] Add 278.4kg N,N-dimethyl-butylene diamine (2400 moles) and 242.4kg triethylamine (2400 moles) into a 2500L reactor with reflux, add 600L tetrahydrofuran, and stir evenly. Add 604.0kg perfluorobutylsulfonyl fluoride (2000 moles) to it, heat up to 100°C after all the addition, react for 12 hours, evaporate the solvent and excess amine under reduced pressure, wash with water, filter, and dry the filter residue to obtain C 4 f 9 SO 2 NH(CH 2 ) 4 N(CH3 ) 2 666.2kg, yield 83.7%. 99.5kgC 4 f 9 SO 2 NH(CH 2 ) 4 N(CH 3 ) 2 (250 moles) was placed in a 1000L reactor, and 120L of ethanol was added and stirred to dissolve it. 33.6kg of propane sultone (275 moles) was dissolved in 200L of ethanol and added to the reactor, and the temperature was raised to 90°C after stirring and mixing. React for 7 hours, cool, crystallize, filter, and dry the filter residue to obtain F4H4N(CH 3 )(CH 3 ) S98.3kg, yield 75.6%. Take 1.00kgF4H4N(CH 3 )(CH 3 )S, add 4.00kg deionized wate...

Embodiment 3

[0044] Add 224.4kg N,N-dimethyl-propylenediamine (2200 moles) and 323.2kg triethylamine (3200 moles) into a 2500L reactor with reflux, add 650L tetrahydrofuran, and stir evenly. Add 604.0kg perfluorobutylsulfonyl fluoride (2000 moles) to it, heat up to 70°C after all the addition, react for 10 hours, evaporate the solvent and excess amine under reduced pressure, wash with water, filter, and dry the filter residue to obtain C 4 f 9 SO 2 NH(CH 2 ) 3 N(CH 3 ) 2 696.5kg, yield 90.7%. 192kgC 4 f 9 SO 2 NH(CH 2 ) 3 N(CH 3 ) 2 (500 mol) in a 2500L reactor, add 200L of ethanol and stir to dissolve it, add 102.0kg of 35% hydrogen peroxide (1050 mol) aqueous solution into the reactor, stir, heat up to 70°C, react for 5 hours, and cool. Ethanol was evaporated under reduced pressure, crystallized by cooling, filtered, and the filter residue was dried to obtain F4H3N(CH 3 )(CH 3 ) O176.2kg, yield 88.1%. Take 1.00kgF4H3N(CH 3 )(CH 3 )O, add 4.00kg deionized water, mix to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com