Cementing agent for micro-fine-particle tailing cementing filling

A technology of cemented filling and cementing agent, which is applied in the field of tailings cemented filling materials, can solve the problems of low consolidation strength, difficulty in solidification, and slow settlement speed of ultra-fine full tails, so as to reduce construction investment and maintenance costs, and achieve good early strength Performance and cementation performance, and the effect of reducing the cost of backfill mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further describe the present invention, a cementing agent for cementing and filling fine tailings of the present invention will be described in detail below in conjunction with examples. However, the present invention is not limited to the Examples.

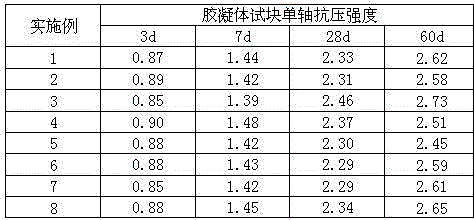

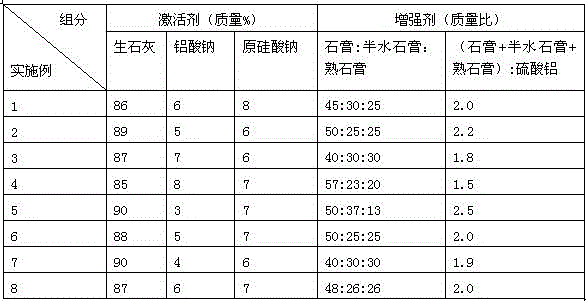

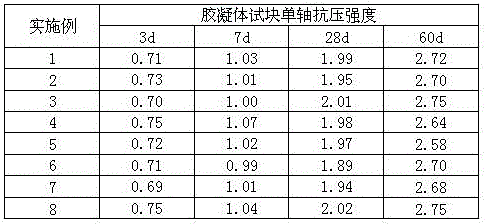

[0031] The present invention is a kind of cementing agent for fine grain tailings cementation filling, which is to mix various raw materials according to a certain mass ratio, and grind them into a specific surface area ≥ 600m 2 / kg of powder, that is, the required gelling material is obtained. The cement is mixed with the concentrated tailings in the mine filling station in a certain proportion, stirred evenly, and transported to the underground goaf by pumps and pipelines for filling. The mass concentration of filling and conveying is generally between 55% and 70%, preferably 60% to 70%. Detect the strength of the 3d, 7d, 28d, and 60d filling body to check the technical effect of the cement of the present i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com