Main catalyst component for alkene polymerization and catalyst

A technology of olefin polymerization and main catalyst, applied in the field of catalysts, can solve problems such as difficult stability control, achieve narrow particle size distribution, reduce production costs, and easily obtain raw material components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Preparation of main catalyst components

[0061] 1) Weigh 10.2g of magnesium chloride, add 78mL of tetra-n-butoxytitanium (hereinafter also referred to as "tetrabutyl titanate"), stir and dissolve at 140°C until a transparent mixed solution is formed, and lower the temperature of the mixed solution to to room temperature, add 200mL of dry hexane to dilute and set aside.

[0062] 2) Take 20 mL of the mixed solution obtained in the above step 1), and slowly drop the mixed solution into the mixed solution formed by 30 mL of hexane and 20 mL of silicon tetrachloride at room temperature. After the dropwise addition, the reaction was stirred and reacted at a bath temperature of 45° C. for 1 hour, and at a bath temperature of 65° C. for 2 hours, thereby obtaining a solid suspension.

[0063] 3) Add 0.3 mL of phthaloyl chloride to the solid suspension obtained in the above step 2, stir and react at 90° C. for 1 hour, stop stirring, and let the solid settle. After removing th...

Embodiment 2

[0076] Except that the amount of phthaloyl chloride in step 3) was adjusted from 0.3 milliliters to 0.5 milliliters, the main catalyst component was prepared in the same manner as in Example 1.

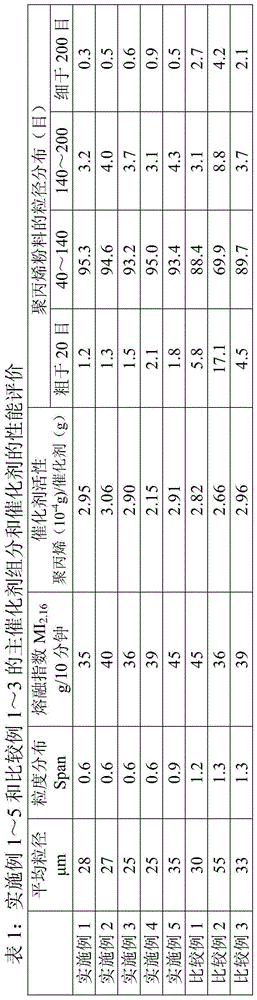

[0077] The results of average particle diameter and particle size distribution measurement show that the average particle diameter (D 50 ) was 26 μm, and the particle size distribution width (Span) was 0.7. The catalyst activity and the sieving results of the polypropylene powder are shown in Table 1 below.

Embodiment 3

[0079] The main catalyst component was prepared in the same manner as in Example 1, except that the amount of titanium tetrachloride in step 4) was adjusted from 2.3 milliliters to 1.0 milliliters.

[0080] The results of average particle diameter and particle size distribution measurement show that the average particle diameter (D 50 ) was 27 μm, and the particle size distribution width (Span) was 0.7. The catalyst activity and the sieving results of the polypropylene powder are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com