Zwitter-ion waterborne polyurethane resisting protein and microorganism adsorption

A water-based polyurethane and microbial adsorption technology, applied in polyurea/polyurethane coatings, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

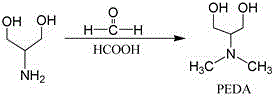

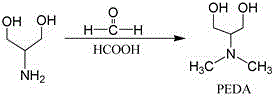

[0024] The specific process of PEDA preparation reaction is as follows: Weigh 0.5mol (45.6g) of 2-amino-1,3-propanediol, Mn=91.11 in a 250ml three-neck flask, add 153ml of formic acid, immediately add 70ml of 37% formaldehyde solution, and After mixing and stirring for 2 hours, the temperature was raised to 80° C. for 8 hours (during this process, gas would be released continuously). Cool down to 25°C, add 90ml of 37% HCl, and stir for 1h. Then an appropriate amount of NaOH was added to adjust the pH to 12, the mixture was distilled under reduced pressure, concentrated, and the solvent was removed. Add excess methanol, filter to remove salts, and concentrate the filtrate under reduced pressure to obtain the pure product as white crystals;

[0025] Weigh 20.00g polyoxypropylene glycol (M n =2000), added to a 250ml three-necked flask, dehydrated and dried in vacuum at 110°C for 2h, then lowered the temperature to 70°C, added 3.48g of toluene diisocyanate and 100ml of tetrahydr...

Embodiment 2

[0027]The specific process of PEDA preparation reaction is as follows: Weigh 0.5mol (45.6g) of 2-amino-1,3-propanediol, Mn=91.11 in a 250ml three-neck flask, add 153ml of formic acid, immediately add 70ml of 37% formaldehyde solution, and After mixing and stirring for 2 hours, the temperature was raised to 80° C. for 8 hours (during this process, gas would be released continuously). Cool down to 25°C, add 90ml of 37% HCl, and stir for 1h. Then an appropriate amount of NaOH was added to adjust the pH to 12, the mixture was distilled under reduced pressure, concentrated, and the solvent was removed. Add excess methanol, filter to remove salts, and concentrate the filtrate under reduced pressure to obtain the pure product as white crystals;

[0028] Weigh 20.00g polytetrahydrofuran (M n =2000), added to a 250ml three-necked flask, dehydrated and dried under vacuum at 110°C for 2 hours, then lowered the temperature to 60°C, added 5g of diphenylmethane diisocyanate (dissolved in ...

Embodiment 3

[0030] The specific process of PEDA preparation reaction is as follows: Weigh 0.5mol (45.6g) of 2-amino-1,3-propanediol, Mn=91.11 in a 250ml three-neck flask, add 153ml of formic acid, immediately add 70ml of 37% formaldehyde solution, and After mixing and stirring for 2 hours, the temperature was raised to 80° C. for 8 hours (during this process, gas would be released continuously). Cool down to 25°C, add 90ml of 37% HCl, and stir for 1h. Then an appropriate amount of NaOH was added to adjust the pH to 12, the mixture was distilled under reduced pressure, concentrated, and the solvent was removed. Add excess methanol, filter to remove salts, and concentrate the filtrate under reduced pressure to obtain the pure product as white crystals;

[0031] Weigh 10.00g polytetrahydrofuran (M n =1000), added to a 250ml three-necked flask, dehydrated and dried under vacuum at 110°C for 2h, then lowered the temperature to 60°C, added 4.5g of isophorone diisocyanate and 100ml of tetrahyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com