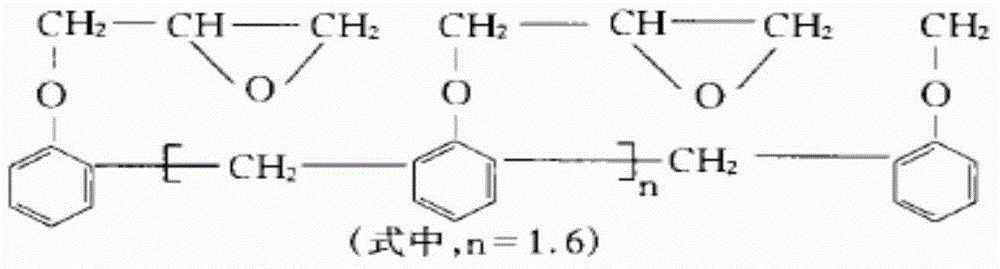

Solvent-free epoxy phenolic coating

A technology of coatings and anti-corrosion coatings, which is applied in the direction of epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of poor acid resistance and achieve excellent chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

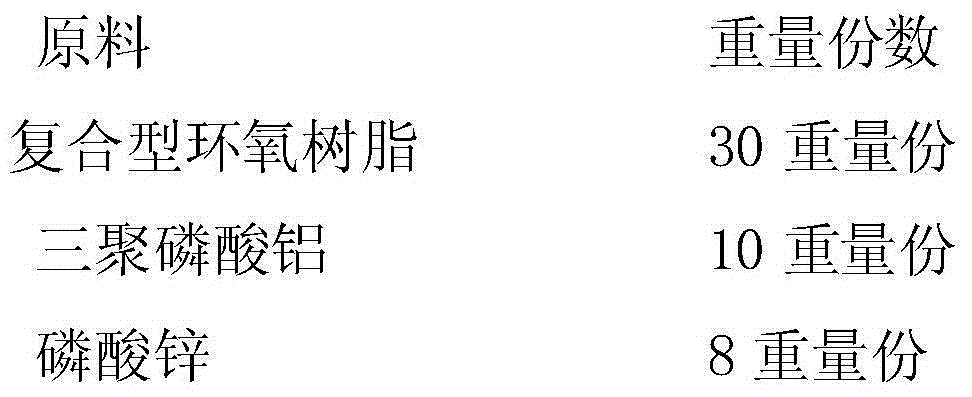

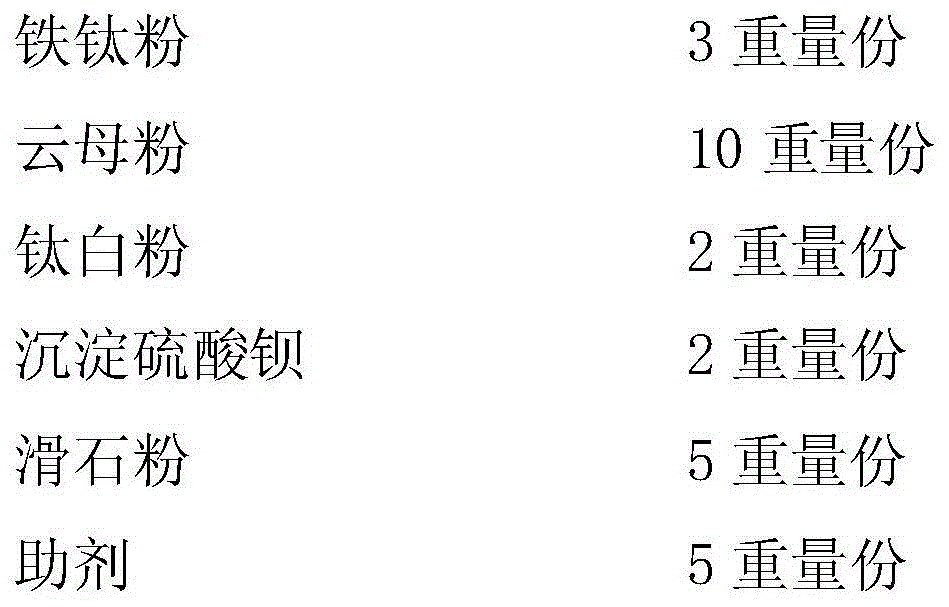

[0032] Weigh 30 parts by weight of composite epoxy resin, put it into a stainless steel tank and stir it with a high-speed disperser, add 2 parts by weight of defoamer, 1.5 parts by weight of wetting and dispersing agent, and 1.5 parts by weight of leveling agent, and stir with the resin evenly Add 2 parts by weight of titanium dioxide, 5 parts by weight of talcum powder, 10 parts by weight of aluminum tripolyphosphate, 8 parts by weight of zinc phosphate, 3 parts by weight of iron-titanium powder, 10 parts by weight of mica powder, and 2 parts by weight of barium sulfate, and stir evenly, then Grind to standard fineness with a sand mill or three-roll mill, filter and pack into paint A component.

[0033] Weigh 23 parts by weight of the modified alicyclic amine curing agent and 2 parts by weight of the curing accelerator, stir evenly with a high-speed disperser, filter and pack into a bucket to become component B of the coating.

[0034] When using, mix the two components of A...

Embodiment 2

[0039] It is used in a ship chemical tank in Qingdao shipyard. Construction temperature: 8-15°C; construction method: high-pressure airless spraying, two coats with an interval of no more than 24 hours; paint film thickness: 320±20μm. During construction, the bulkhead surface shall be sandblasted to Sa2.5. Using the coating prepared in Example 1, the two components A and B are weighed by the weight ratio of A:B=3:1, mixed and stirred evenly, and sprayed by special high-pressure airless spraying equipment, and the obtained coating is smooth and smooth. The surface is bright. Use the coating after curing for seven days at room temperature (25°C), and check after 12 months that the coating is intact.

Embodiment 3

[0041] at a certain 2000m 3 The inner wall of carbon steel methanol storage tank is used. Construction temperature: 15-20°C; construction method: high-pressure airless spraying, two coats, with an interval of no more than 24 hours; paint film thickness: the tank wall is not less than 200 μm, and the tank bottom is not less than 300 μm. During construction, the surface of the inner wall of the storage tank shall be sandblasted to Sa2.5. Using the coating prepared in Example 1, the A and B components are weighed and matched in parts by weight of A:B=3:1, stirred evenly, and sprayed by special high-pressure airless spraying equipment, and the obtained coating is smooth, The surface is bright. The coating is cured at room temperature (25°C) for seven days and used, and checked after 12 months. There is no blistering and falling off, and the coating is intact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com