A method for preparing carbon nanofibers by electrospinning

A carbon nanofiber and electrospinning technology, which is applied in the manufacture of conductive/antistatic filaments, fiber chemical characteristics, textiles and papermaking, etc., can solve the high cost of carbon nanofiber preparation, difficulty in mass production, and many uncontrollable factors etc. to achieve the effects of low price, reduced preparation cost and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] A method for preparing carbon nanofibers by electrospinning, comprising the following steps:

[0025] (1) Preparation of precursor solution: dissolve 1-3wt% acetic acid in 100ml ethanol solution to prepare an organic solvent; add a concentration of 2-5wt% polymer and a 2-10wt% lamellar structure to the organic solvent Graphite is subjected to ultrasonic treatment to obtain a homogeneously mixed precursor solution; in this embodiment, polyvinylpyrrolidone is selected as the polymer, and graphene is selected as the graphite with sheet structure; the ambient temperature for ultrasonic treatment is 60°C, the power is greater than 100W, and at least Carry out for 24 hours to ensure that graphene is evenly dispersed in polyvinylpyrrolidone;

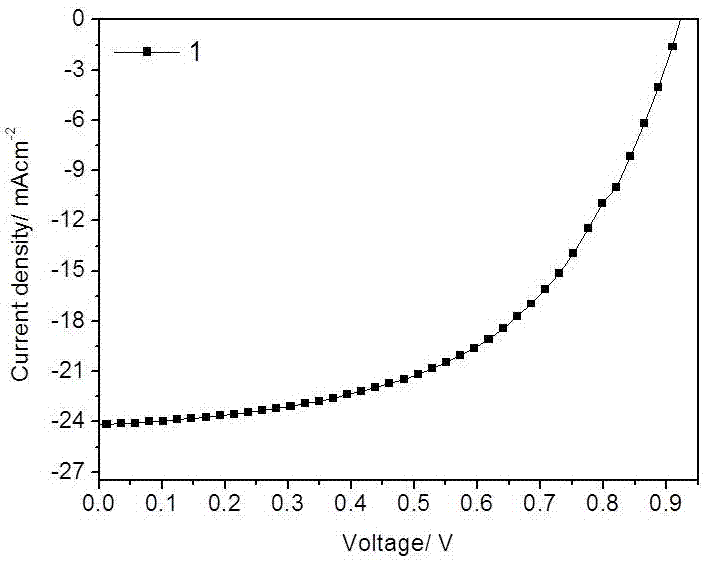

[0026] (2) carry out electrospinning to polyvinylpyrrolidone / graphene mixed homogeneous precursor solution, prepare polymer / carbon nanocomposite fiber; In order to ensure that the diameter of carbon nanofiber is between 200nm-500nm, in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com