Secondary combustion chamber furnace door device of precious metal recovery plasma furnace

A technology of plasma furnace and secondary combustion chamber, which is applied in the field of ion smelting furnace to recover precious metals and precious metal smelting equipment. It can solve the problems of inaccurate position when closing the door, wear of the refractory body of the furnace door, and potential safety hazards, so as to prevent potential safety hazards, Extended service life and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

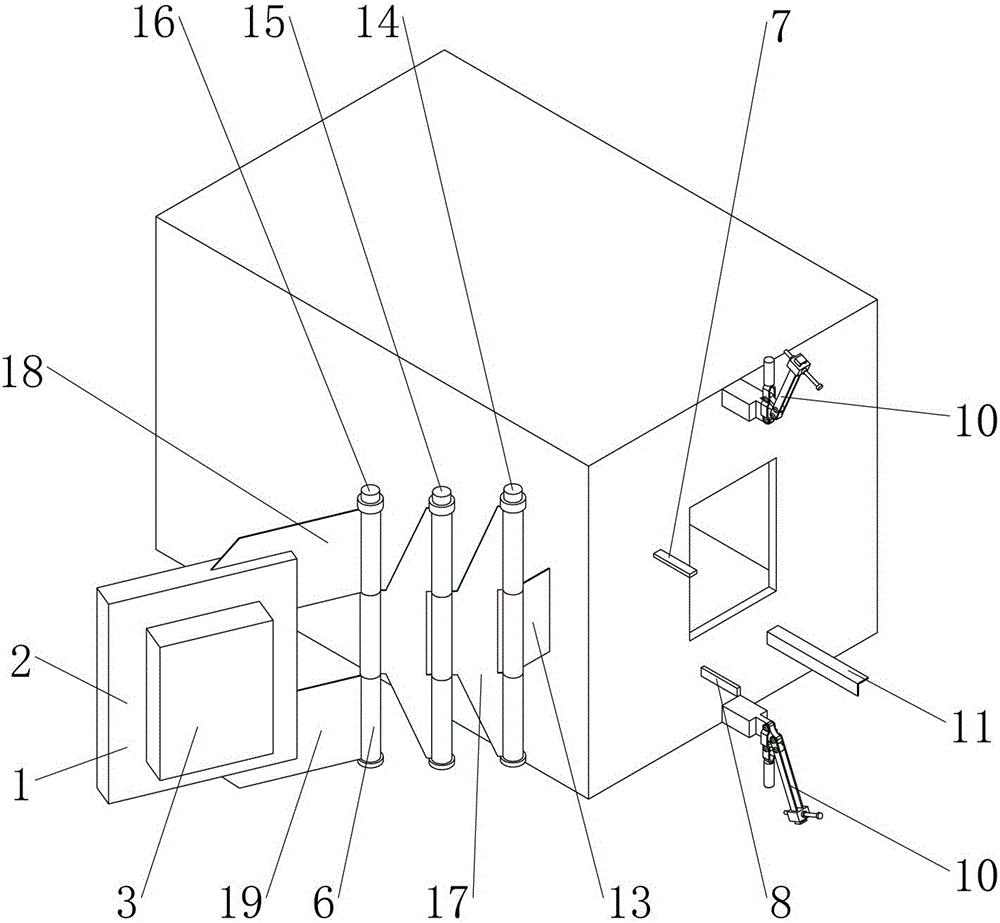

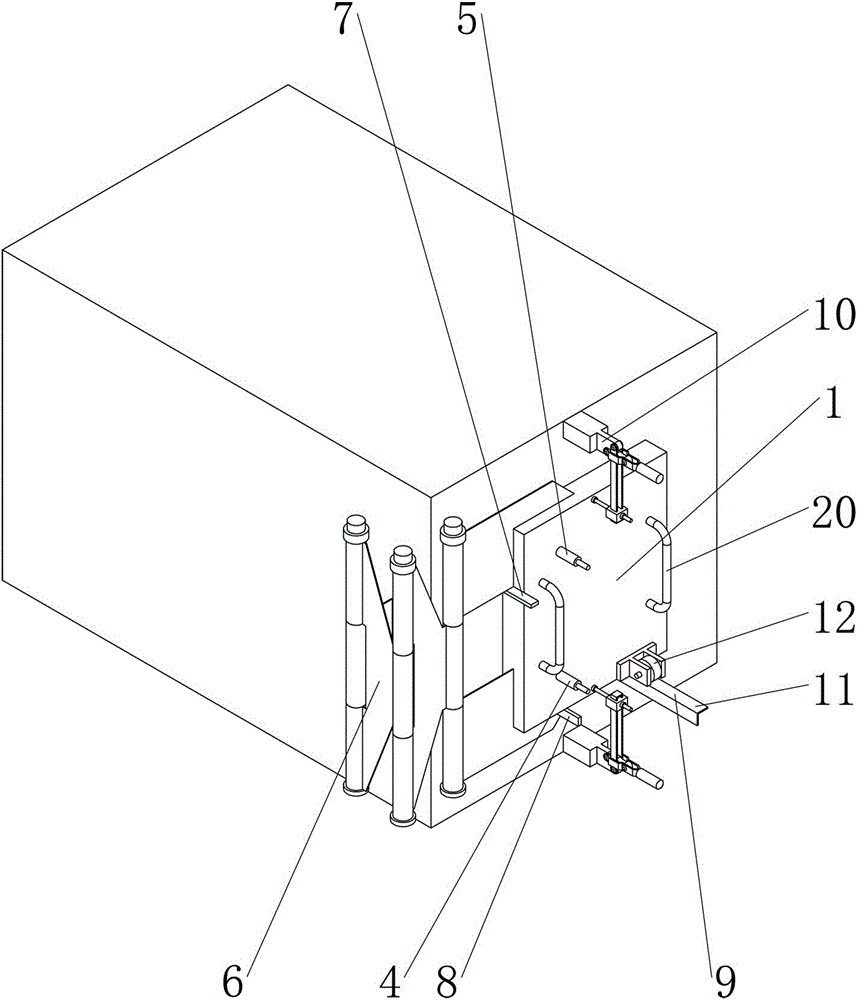

[0025] Such as figure 1 , figure 2 As shown, the furnace door device for the second combustion chamber of the plasma furnace for recovering precious metals includes a furnace door 1 that covers the furnace mouth. The lower part of the outer side of the hollow furnace door 2 is provided with a cooling water inlet 4, and the upper part of the outer side of the hollow furnace door 2 is provided with a cooling water outlet 5, and also includes a rotating shaft mechanism 6, a side positioning plate 7, a lower positioning plate 8, a sliding system 9 and a clamp 10 ; The sliding system 9 is made up of a track 11 and a sliding wheel 12;

[0026] The outer side wall of the second combustion chamber is provided with a rotating shaft mechanism 6. The rotating shaft mechanism 6 includes a rotating shaft fixing plate 13, a first rotating shaft 14, a second rotating shaft 15, a third rotating shaft 16, a rotating shaft connecting plate 17, an upper fixed furnace door plate 18 and a lower...

Embodiment 2

[0035] The furnace door device for the second combustion chamber of the plasma furnace for recovering precious metals is implemented as in Example 1, except that the clamp is a crank rocker cam locking device. The crank rocker cam locking device adopts the crank rocker and cam locking mechanism, which has simple structure, convenient operation, fast and flexible clamping, and the cam angle is fixed within the self-locking angle when locking, which is safe and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com