Long-lifetime neutron tube with ceramic-head ion source

A technology of ion source and ceramic head, which is applied in the field of long-life neutron tubes, can solve the problems of difficult manufacturing, easy oxidation and deformation of copper heads, and difficulty in miniaturization, so as to achieve good consistency of technical parameters, avoid eccentricity and distortion, Effect of improving stability and pulse characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

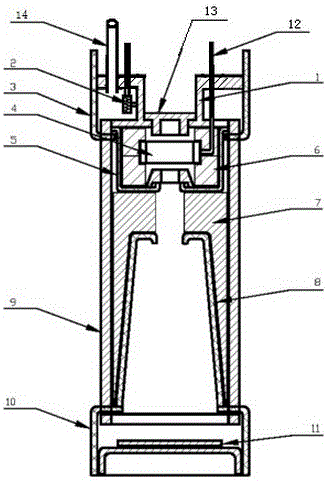

[0008] The long-life neutron tube of the ceramic head ion source of the present invention is a circular axisymmetric structure, which seals the ceramic ion source, acceleration system, target and air pressure adjustment system in a ceramic tube, forming a simple, compact and easy-to-use neutron tube. The electric vacuum device, its structure and positional relationship are shown in the accompanying drawings. First, the upper part of the ceramic head 1 to be sealed with the upper cover 3 is metallized, the three metal electrodes 12, the exhaust pipe 14 and the ion source cathode 13 are brazed to the ceramic head 1 and chemically cleaned, and the target 11 After the processing is completed and the chemical cleaning is done, coat the film on the magnetron sputtering coating machine; then seal the upper cover 3, the ion source cover 5, the acceleration gap ceramic insulating ring 7, the acceleration cylinder 8, the lower cover 10 and the ceramic shell 9 connected together. The ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com