Preparation method of a ceramic hollow fiber solvent-resistant composite nanofiltration membrane

A composite nanofiltration membrane, solvent-resistant technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effect of improving the application field, environmental friendliness, excellent chemical stability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

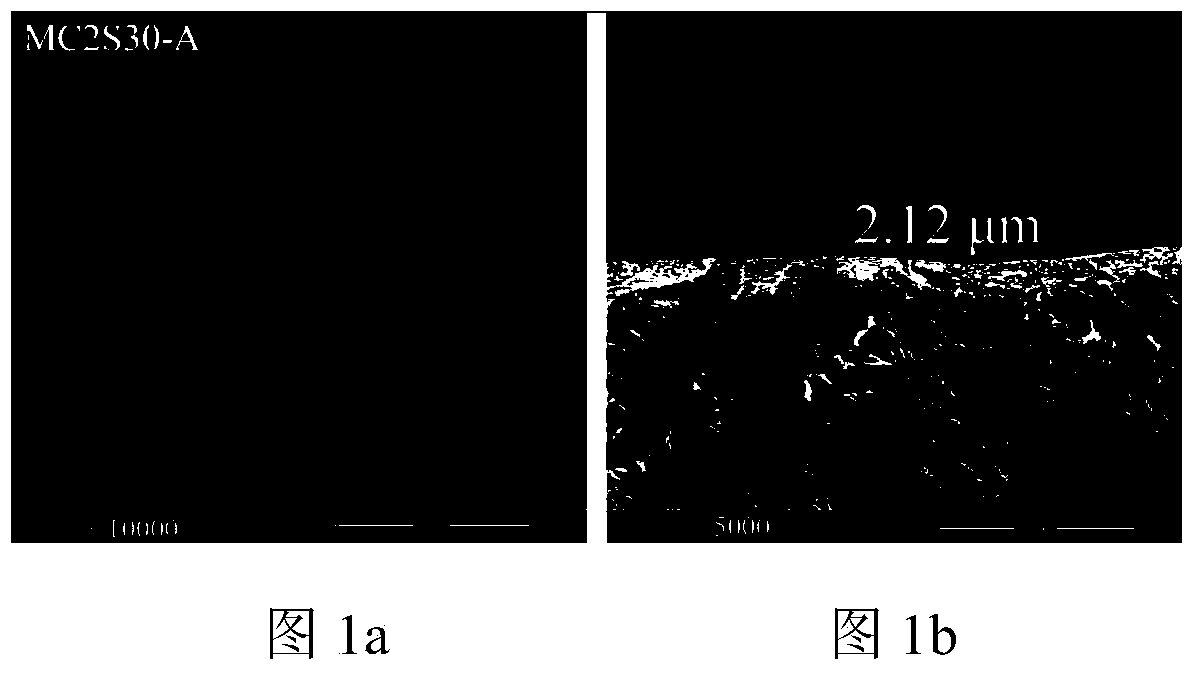

[0044] Preparation of γ-Al 2 o 3 / α-Al 2 o 3 Hollow fiber solvent-resistant composite nanofiltration membrane for the removal of salt ions in water

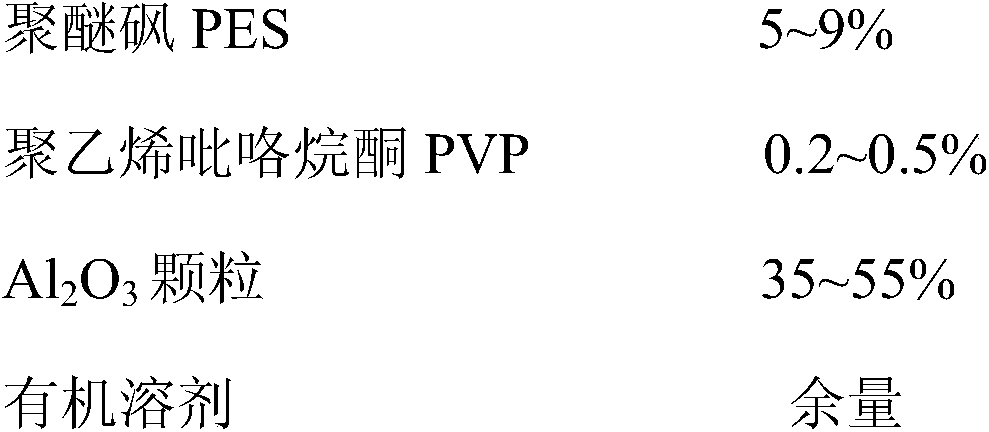

[0045] 1. Under the water condition of 70°C, according to the mass ratio polyethersulfone (PES): polyvinylpyrrolidone (PVP): Al 2 o 3 Particles: 1-methyl-2-pyrrolidone = 8: 0.5: 50: 41.5, stir and mix evenly, keep for more than 24 hours to obtain a uniform and stable casting solution; prepare α-Al by wet spinning method 2 o 3 Hollow fiber ceramic base membrane, soaked in pure water for 24 hours, dried and sintered in an electric furnace with programmed temperature rise, after sintering, naturally cool down to obtain the finished membrane;

[0046] 2. Add 10.5g aluminum isopropoxide (Al(OC 3 h 7 ) 3 ) slowly added in batches to 90g of deionized water mechanically stirred at 85°C, after hydrolysis for 2 hours, the isopropanol produced by the reaction was removed, and 0.7875g of debonding agent HNO was added 3 After aging ...

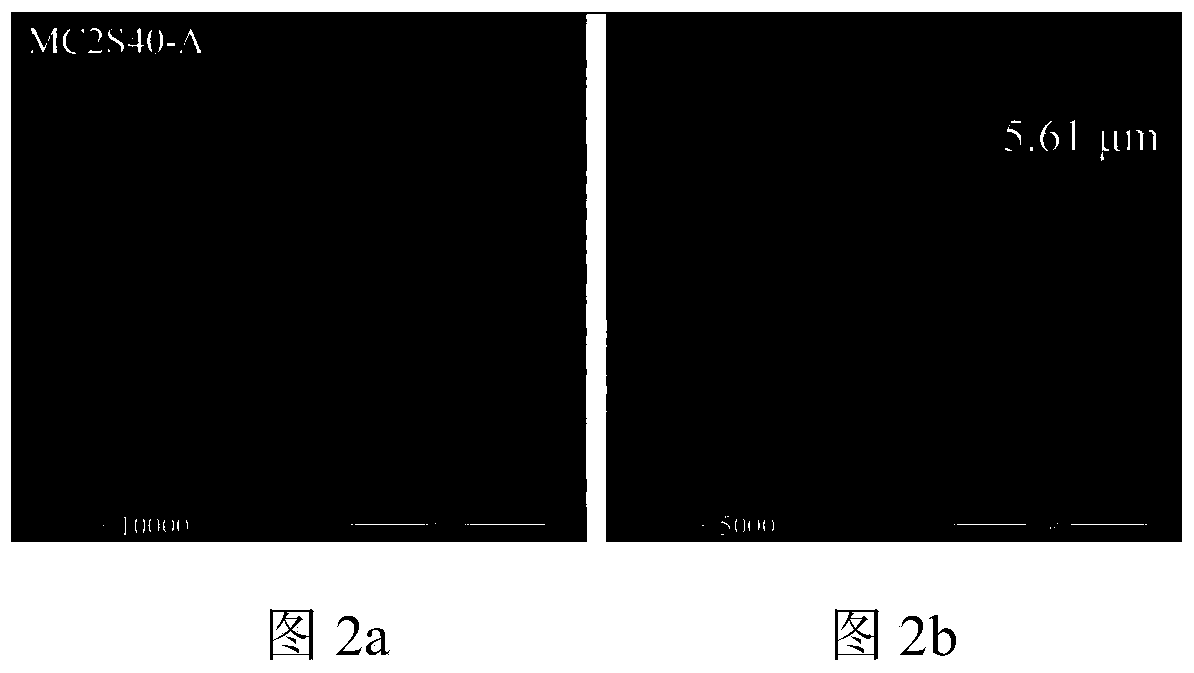

Embodiment 2

[0050] Under the condition of 70°C waters, the mass ratio of polyethersulfone (PES): polyvinylpyrrolidone (PVP): Al 2 o 3 Particles: 1-methyl-2-pyrrolidone = 8: 0.5: 50: 41.5, stir and mix evenly, keep for more than 24 hours to obtain a uniform and stable casting solution; prepare α-Al by wet spinning method 2 o 3 Hollow fiber ceramic base membrane, soaked in pure water for 24 hours, dried and sintered in an electric furnace with programmed temperature rise, after sintering, naturally cool down to obtain the finished membrane;

[0051] 2. Put 10.2g aluminum isopropoxide (Al(OC 3 h 7 ) 3 ) slowly added in batches to 90g of deionized water mechanically stirred at 85°C, after hydrolysis for 2 hours, the isopropanol produced by the reaction was removed, and 0.7875g of debonding agent HNO was added 3 After aging in a water bath at 90°C for 12 hours, add 30 mL of 5wt.% PVA solution and continue stirring for 3 hours to finally obtain γ-AlOOH sol;

[0052] 3. Apply the γ-AlOOH s...

Embodiment 3

[0055] Under the condition of 70°C waters, the mass ratio of polyethersulfone (PES): polyvinylpyrrolidone (PVP): Al 2 o 3 Particles: 1-methyl-2-pyrrolidone = 8: 0.5: 50: 41.5, stir and mix evenly, keep for more than 24 hours to obtain a uniform and stable casting solution; prepare α-Al by wet spinning method 2 o 3 Hollow fiber ceramic base membrane, soaked in pure water for 24 hours, dried and sintered in an electric furnace with programmed temperature increase, after sintering, naturally cool down to obtain the finished membrane;

[0056] 2. Put 20.4g aluminum isopropoxide (Al(OC 3 h 7 ) 3 ) slowly added in batches to 180g of deionized water mechanically stirred at 85°C, after hydrolysis for 2 hours, the isopropanol produced by the reaction was removed, and 1.575g of debonding agent HNO was added 3 After aging in a water bath at 90°C for 12 hours, add 30 mL of 10wt.% PVA solution and continue stirring for 3 hours to finally obtain γ-AlOOH sol;

[0057] 3. Apply the γ-AlOO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com