Method for extracting aluminum oxide from coal ash on basis of lime sinter process

A lime sintering and fly ash technology, which is applied in the direction of alumina/aluminum hydroxide, alkaline earth metal silicate, silicate, etc., can solve the problems of high energy consumption and high cost, and achieve low sintering energy consumption, high temperature and The effect of large output and suitable for large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

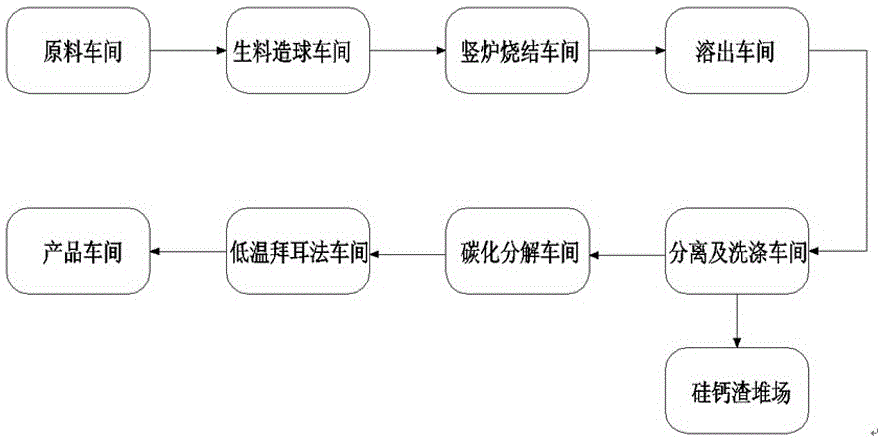

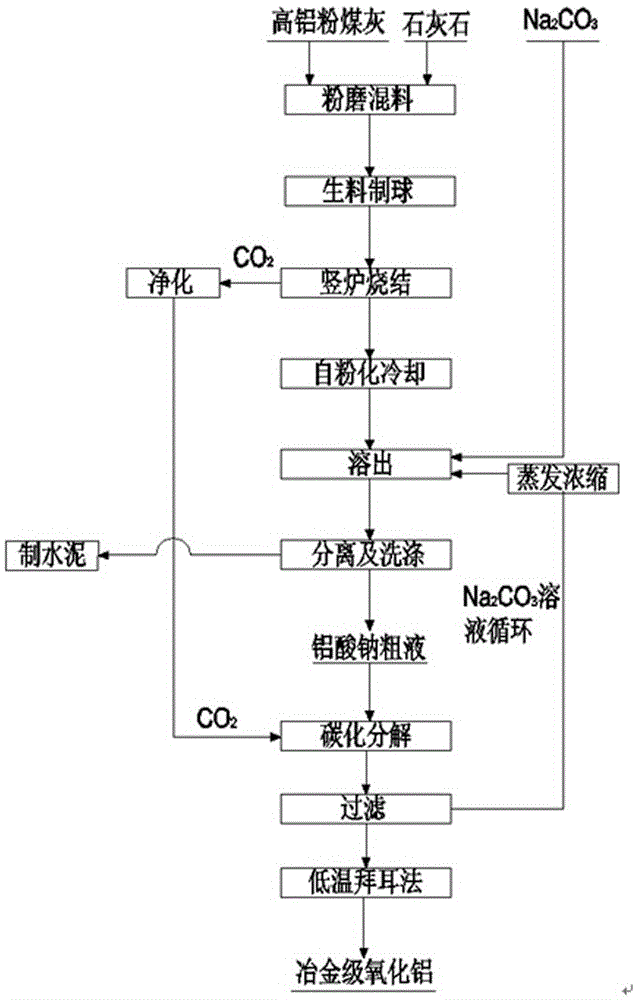

Method used

Image

Examples

Embodiment 1

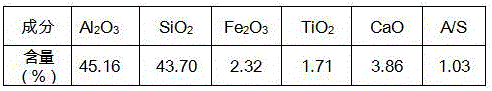

[0028] (1) Grinding and mixing: Add 80Kg of fly ash and 146Kg of lime into the mixer (ball mill) for grinding and mixing, and the mixture is ground to 200 mesh;

[0029] ⑵Raw meal ball making: use the mixed material prepared in the ⑴ step and the dilute solution of slaked lime (binder) (mass concentration is 5%-6%), use high-frequency vibrating pressure agglomeration to make balls, and dry them at low temperature High-aluminum fly ash sintered pellets; the obtained high-alumina fly ash sintered pellets have a particle size of 4-8mm and a moisture content of less than 6%;

[0030] (3) Shaft furnace roasting: the high-aluminum fly ash sintered pellets are evenly distributed in the shaft furnace, and after five stages of drying, preheating, roasting, soaking, and cooling, the raw meal balls are roasted into mature pellets; the roasting temperature 1300°C-1450°C, baking time 40 minutes;

[0031] ⑷ Self-powdering cooling: first cool the clinker to 500-550°C in the self-powdering c...

Embodiment 2

[0038] (1) Grinding and mixing: Add 60Kg of fly ash and 110Kg of lime into the mixer (ball mill) for grinding and mixing, and the mixture is ground to 200 mesh;

[0039] ⑵Raw meal ball making: use the mixed material prepared in the ⑴ step and the dilute solution of slaked lime (binder) (mass concentration is 5%-6%), use high-frequency vibrating pressure agglomeration to make balls, and dry them at low temperature High-aluminum fly ash sintered pellets; the obtained high-alumina fly ash sintered pellets have a particle size of 4-8mm and a moisture content of less than 6%;

[0040] (3) Shaft furnace roasting: the high-aluminum fly ash sintered pellets are evenly distributed in the shaft furnace, and after five stages of drying, preheating, roasting, soaking, and cooling, the raw meal balls are roasted into mature pellets; the roasting temperature 1300°C-1450°C, baking time 40 minutes;

[0041] ⑷ Self-powdering cooling: first cool the clinker to 500-550°C in the self-powdering c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com