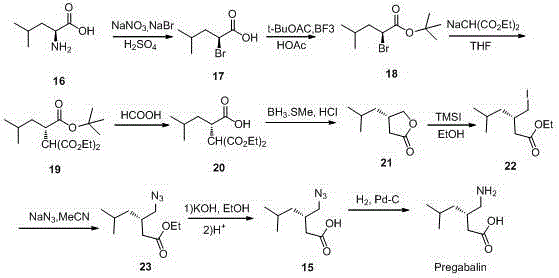

Preparation method for asymmetrical synthesis of pregabalin

A pregabalin and asymmetric technology is applied in the preparation field of asymmetric synthesis of pregabalin, can solve the problems of low yield, long synthesis route of pregabalin, need to split, etc., achieves few steps, novel synthesis route, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

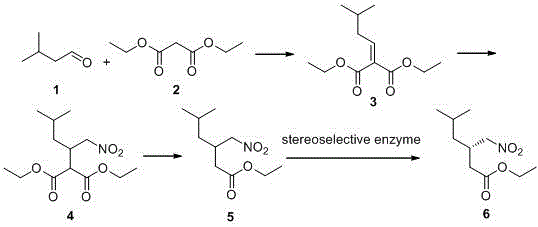

Method used

Image

Examples

Embodiment 1

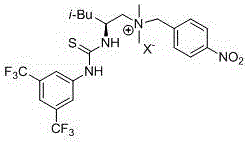

[0040] 1. Catalytic asymmetric alcoholysis

[0041] Take a 100mL three-necked flask, add 3-isobutylglutaric anhydride (1.70g, 0.01mol), bromide (S)-2-(3(3,5-bis(trifluoro Methyl)phenyl)thioureido)-N,N,4-trimethyl-N-(4-nitrobenzyl)pentan-1-ammonium (630mg, 1.0mmol), and 50mL THF was added to dissolve the solid, Benzylthiol (1.50g, 0.012mol) was added under stirring at -10°C, reacted for 16h, the solvent was removed under reduced pressure, and purified by column chromatography to obtain 2.80g of thiol ester with a yield of 95% and an ee value of 94%.

[0042] 2. Synthesis of benzyloxycarbamide methyl thiol ester

[0043] Take a 100mL three-necked flask, dissolve thiol ester (2.80g, 9.5mmol) in dry toluene at 25°C, add triethylamine (0.97g, 9.6mmol) and diphenylphosphoryl azide (2.64g, 9.6mmol), stirred for 15min, then slowly raised the temperature to 85°C, when no bubbles emerged from the system, slowly added benzyl alcohol (1.08g, 10.0mmol) and stirred and refluxed for 12h. ...

Embodiment 2

[0049] 1. Catalytic asymmetric alcoholysis

[0050] Take a 100mL three-necked flask, add 3-isobutylglutaric anhydride (1.70g, 0.01mol), chloride (S)-2-(3(3,5-bis(trifluoro Methyl)phenyl)thioureido)-N,N,4-trimethyl-N-(4-nitrobenzyl)pentan-1-ammonium (590mg, 1.0mmol), and added 50mL methyl tert-butyl Dissolve the solid in base ether, add benzyl mercaptan (1.50g, 0.012mol) under stirring at -10°C, react for 16h, remove the solvent under reduced pressure, and purify by column chromatography to obtain 2.84g of thiol ester with a yield of 96% and an ee value 95%.

[0051] 2. Synthesis of benzyloxycarbamide methyl thiol ester

[0052] Take a 50mL three-necked flask, dissolve thiol ester (1.42g, 4.8mmol) in dry toluene at 25°C, add triethylamine (0.49g, 4.8mmol) and diphenylphosphoryl azide (1.324g, 4.8mmol), stirred for 15min, then slowly raised the temperature to 85°C, when no bubbles emerged from the system, slowly added benzyl alcohol (0.54g, 5.0mmol) and stirred and refluxed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com