Degradable antibacterial preservation material and preparation method thereof

A fresh-keeping material, nano-zinc oxide technology, applied in the field of fresh-keeping materials, can solve the problems of antibacterial and fresh-keeping performance not meeting the fresh-keeping requirements, and achieve the effect of improving anti-bacterial and fresh-keeping functions, reducing moisture permeability, and changing the penetration path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

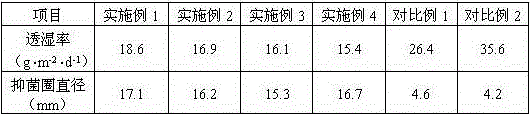

Examples

Embodiment 1

[0017] A degradable antibacterial and fresh-keeping material, comprising the following components in parts by weight: 100 parts of polyvinyl alcohol, 5 parts of nano-zinc oxide, 3 parts of silicon dioxide, 40 parts of polycarbonate, 15 parts of stearic acid, pentadiene 80 parts of aldehyde, 120 parts of ethanol, wherein, the average particle diameter of nanometer zinc oxide is 20±2nm, and the average particle diameter of silicon dioxide is 40±3nm.

[0018] The preparation method of described degradable antibacterial fresh-keeping material, comprises the following steps:

[0019] (1) Weigh each component according to the weight ratio, and set aside;

[0020] (2) Add polyvinyl alcohol, nano-zinc oxide, silicon dioxide, and ethanol into the reaction kettle, stir and mix for 60 minutes, and then ultrasonicate for 20 minutes under 60W;

[0021] (3) Add polycarbonate, stearic acid and glutaraldehyde into the reaction kettle, stir and react for 4 hours at 60°C, and after the reactio...

Embodiment 2

[0023] A degradable antibacterial fresh-keeping material, comprising the following components in parts by weight: 100 parts of polyvinyl alcohol, 0.5 parts of nano-zinc oxide, 0.2 parts of silicon dioxide, 20 parts of polycarbonate, 5 parts of stearic acid, pentadiene 50 parts of aldehyde, 60 parts of ethanol, wherein, the average particle diameter of nano zinc oxide is 20±2nm, and the average particle diameter of silicon dioxide is 40±3nm.

[0024] The preparation method of described degradable antibacterial fresh-keeping material, comprises the following steps:

[0025] (1) Weigh each component according to the weight ratio, and set aside;

[0026] (2) Add polyvinyl alcohol, nano-zinc oxide, silicon dioxide, and ethanol into the reaction kettle, stir and mix for 30 minutes, and then ultrasonicate for 15 minutes at 60W;

[0027] (3) Add polycarbonate, stearic acid and glutaraldehyde into the reaction kettle, stir and react at 100°C for 6 hours, and after the reaction, cool t...

Embodiment 3

[0029] A degradable antibacterial and fresh-keeping material, comprising the following components in parts by weight: 100 parts of polyvinyl alcohol, 1.5 parts of nano-zinc oxide, 0.8 parts of silicon dioxide, 30 parts of polycarbonate, 8 parts of stearic acid, pentadiene 65 parts of aldehyde, 100 parts of ethanol, wherein, the average particle diameter of nano zinc oxide is 20±2nm, and the average particle diameter of silicon dioxide is 40±3nm.

[0030] The preparation method of described degradable antibacterial fresh-keeping material, comprises the following steps:

[0031] (1) Weigh each component according to the weight ratio, and set aside;

[0032] (2) Add polyvinyl alcohol, nano-zinc oxide, silicon dioxide, and ethanol into the reaction kettle, stir and mix for 40 minutes, and then ultrasonicate for 16 minutes under 60W;

[0033] (3) Add polycarbonate, stearic acid and glutaraldehyde into the reaction kettle, stir and react for 4.5 hours at 80°C, and after the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com