Coal tar treatment system

A treatment system, coal tar technology, applied in the treatment of hydrocarbon oil, hydroprocessing process, petroleum industry, etc., can solve the problems of high harshness of raw materials, high solid content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

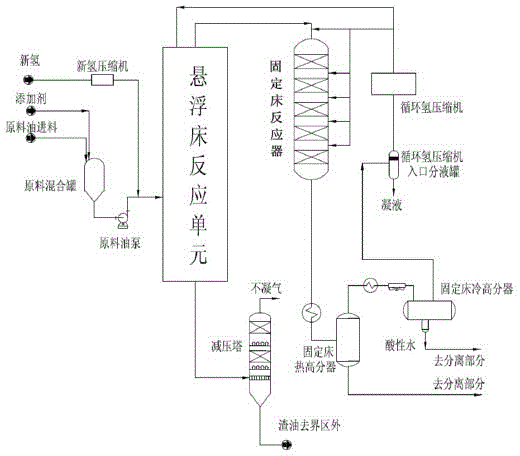

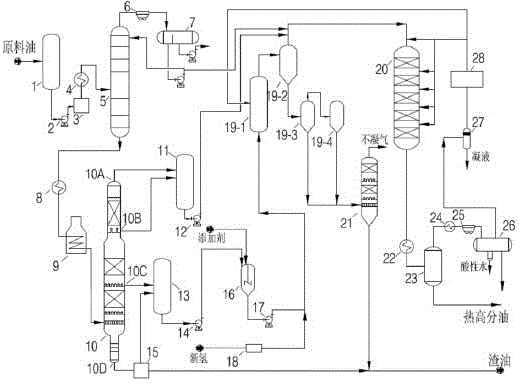

[0071] The present embodiment provides a kind of processing system of coal tar, and its structure is as follows figure 2 shown.

[0072] The coal tar processing system includes: raw oil buffer tank 1, coal tar pump 2, first filter 3, first heat exchanger 4, dehydration tower 5, first air cooler 6, separator 7, second heat exchanger Device 8, coal tar feed furnace 9, coal tar decompression tower 10, light oil mixing tank 11, light oil pump 12, heavy oil mixing tank 13, heavy oil pump 14, second filter 15, raw material mixing tank 16, raw oil pump 17 , new hydrogen compressor 18, suspension bed reactor unit, fixed bed reactor 20, decompression tower 21, third heat exchanger 22, fixed bed heat high pressure separator 23, fourth heat exchanger 24, second air cooler 25. Fixed bed cold high pressure separator 26, circulating hydrogen compressor inlet separator tank 27, circulating hydrogen compressor 28, suspended bed reactor unit includes suspended bed cracking reactor 19-1, hot ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com