Nano bypass filter paper and preparing method thereof

A nano-filter paper technology, applied in the field of filter paper, can solve problems such as low filtration efficiency, high tightness, and short life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

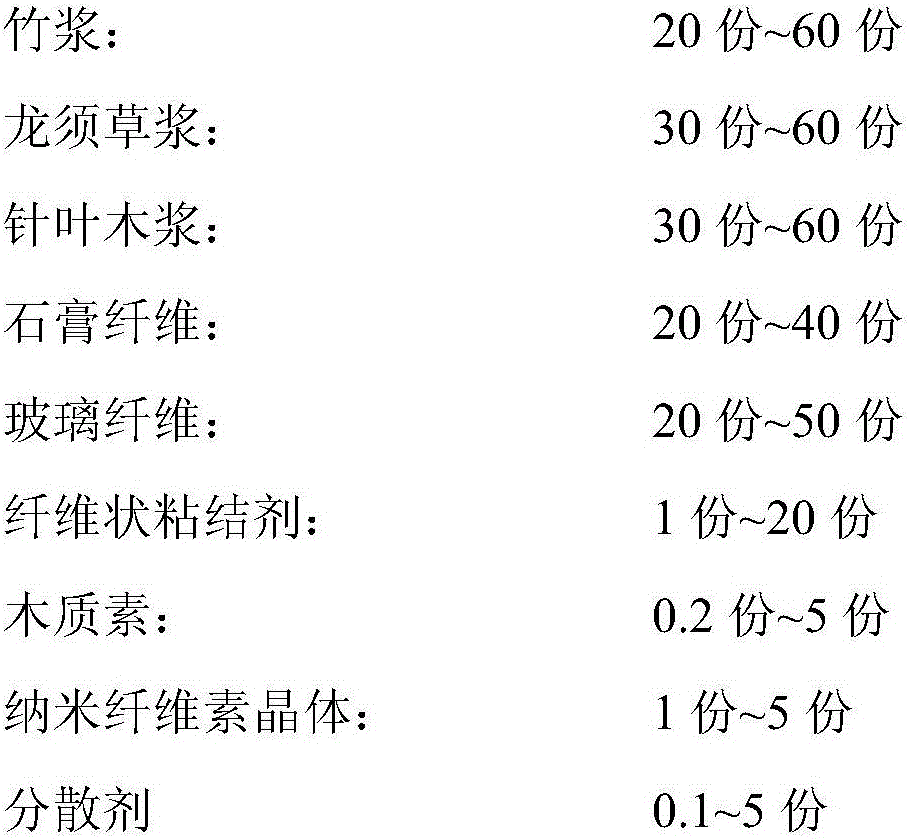

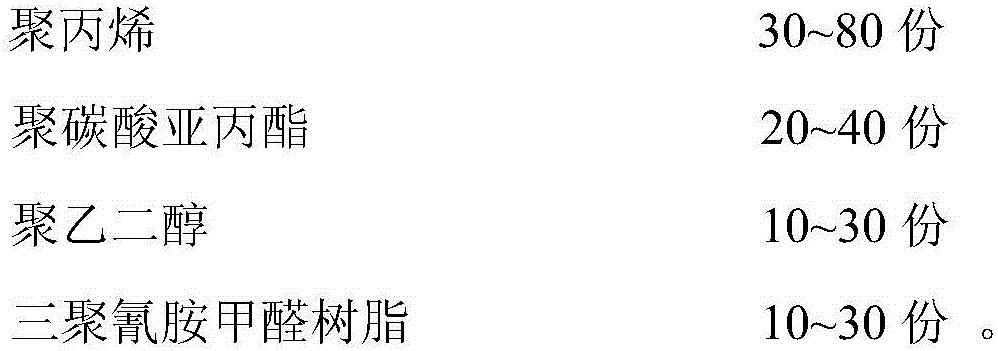

[0030] A nano bypass filter paper, comprising base paper and melt-blown nonwoven fabric, the base paper, in parts by weight, includes 20 parts of bamboo pulp, 30 parts of asparagus pulp, 30 parts of coniferous wood pulp, and 20 parts of gypsum fiber , 20 parts of glass fiber, 1 part of fibrous binder, 0.2 part of lignin, 2.8 parts of nanocellulose crystals, 2.5 parts of dispersant, and the melt-blown nonwoven fabric, by weight parts, includes polypropylene 80 Parts, 40 parts of polypropylene carbonate, 20 parts of polyethylene glycol, 30 parts of melamine formaldehyde resin.

[0031] The fibrous binder is water-soluble PVA fiber; the dispersant includes anionic polyacrylamide; the polypropylene includes polypropylene plastic master batches and polypropylene modified low-melting plastic master batches, and the described The mass ratio of polypropylene plastic masterbatch to polypropylene modified low melting point plastic masterbatch is 6:4.

[0032] The preparation method of ...

Embodiment 2

[0040] A nano bypass filter paper, comprising base paper and melt-blown nonwoven fabric, the base paper, in parts by weight, includes 40 parts of bamboo pulp, 60 parts of asparagus pulp, 40 parts of coniferous wood pulp, and 20 parts of gypsum fiber , 50 parts of glass fiber, 5 parts of fibrous binder, 3 parts of lignin, 2 parts of nanocellulose crystals, 0.5 part of dispersant, and the melt-blown nonwoven fabric, by weight parts, includes 30 parts of polypropylene Parts, 40 parts of polypropylene carbonate, 30 parts of polyethylene glycol, 10 parts of melamine formaldehyde resin.

[0041] The fibrous binder is Weirong fiber; the dispersant includes polyoxyethylene; the polypropylene includes polypropylene plastic masterbatch and polypropylene modified low-melting plastic masterbatch, and the polypropylene The mass ratio of plastic masterbatch to polypropylene modified low melting point plastic masterbatch is 6:4.

[0042] The preparation method of this nano bypass filter pap...

Embodiment 3

[0050] A nano bypass filter paper, comprising base paper and melt-blown nonwoven fabric, said base paper, in parts by weight, includes 50 parts of bamboo pulp, 50 parts of asparagus pulp, 40 parts of coniferous wood pulp, and 25 parts of gypsum fiber , 40 parts of glass fiber, 10 parts of fibrous binder, 2 parts of lignin, 1 part of nanocellulose crystal, 1 part of dispersant, and the melt-blown nonwoven fabric, in parts by weight, includes polypropylene 60 Parts, 30 parts of polypropylene carbonate, 20 parts of polyethylene glycol, 30 parts of melamine formaldehyde resin.

[0051] The fibrous binder is low-melting polyester; the dispersant includes anionic polyacrylamide; the polypropylene includes polypropylene plastic masterbatch and polypropylene modified low-melting plastic masterbatch, and the The mass ratio of polypropylene plastic masterbatch to polypropylene modified low melting point plastic masterbatch is 6:4.

[0052] The preparation method of this nano bypass fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com