Process for purifying nitrogen-containing organic waste gas by adopting photon-generated ozone catalytic oxidation coupled biological method

A technology of ozone catalytic oxidation and organic waste gas, applied in the environmental field, can solve the problems of low pollutant degradation efficiency, low exhaust gas efficiency, secondary pollutants, etc., and achieve the effect of improving degradation efficiency, improving cost performance, and expanding types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Example 1: Purification of waste gas containing acrylonitrile.

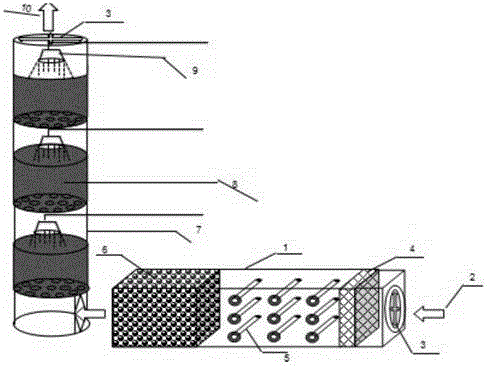

[0011] A process for purifying nitrogen-containing organic waste gas by photo-generated ozone catalytic oxidation coupled with biological method is as follows: figure 1 As shown, it includes a shell 1, an exhaust gas 2, a fan 3, a filter layer 4, an ultraviolet lamp 5, a catalyst 6, a packed tower 7, a packing 8, a shower head 9, and a purified gas 10. The nitrogen-containing volatile organic waste gas 2 enters the photo-generated ozone catalytic oxidation reaction system composed of the ultraviolet lamp 5 and the catalyst 6 after being dedusted and purified by the filter layer 4 under the power transmission of the fan 3, and the nitrogen-containing volatile organic compounds in the exhaust gas. Oxidized into harmless carbon dioxide and water, as well as intermediate products, the incompletely mineralized nitrogen-containing volatile organic waste gas and the generated intermediate products enter the packe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com