Bentonite particles, bentonite particle adsorption column and method for removing phosphorus in natural water body

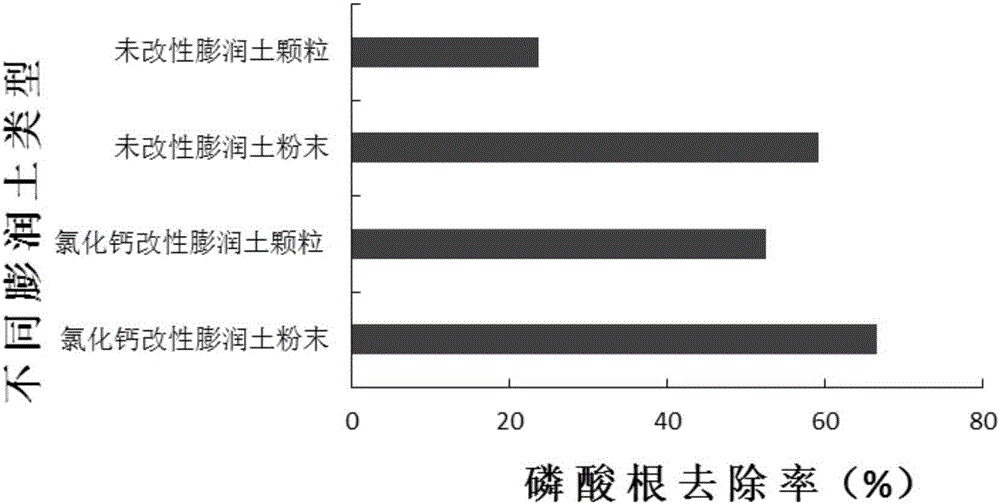

The technology of bentonite and adsorption column is applied in the field of water treatment, which can solve the problem of high cost of adsorbent, and achieve the effects of facilitating separation from water, enhancing fertilizer and water retention performance, and reducing phosphorus content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

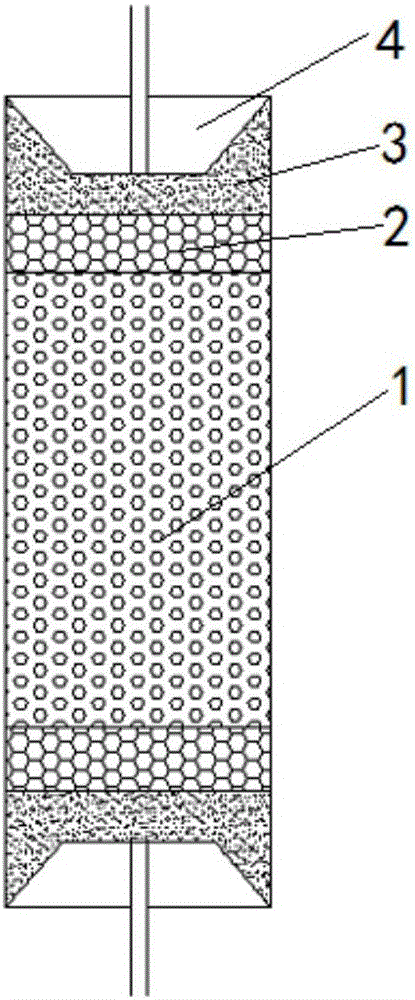

[0036] 1) Mix bentonite and starch at a weight ratio of 100:4, add water and mix evenly to form small balls with a particle size of 3 mm, dry the small balls at a constant temperature of 110 degrees Celsius for 1.5 hours, and dry them at 520 degrees Celsius Calcined for 4h to make granular adsorbent.

[0037] 2) The granular adsorbent that 6g step 1) is obtained is modified in the calcium chloride solution that the concentration of 100mL is 0.09mol / L, and the modification process is carried out in the shaker, and the modification time is 50min, and the shaker speed is Modified at 100r / min, washed with pure water after modification, and modified bentonite particles 1 were obtained.

Embodiment 2

[0039] 1) Mix bentonite and starch in a weight ratio of 100:2, add water and mix evenly to form small balls with a particle size of 5mm, dry the small balls at a constant temperature of 90 degrees Celsius for 2.5 hours, and dry them at 450 degrees Celsius Calcined for 6h to make granular adsorbent.

[0040] 2) The granular adsorbent obtained in 4g step 1) is modified in the calcium chloride solution of 0.12mol / L in the concentration of 100mL, the modification process is carried out in the shaker, the modification time is 30min, and the shaker speed is Modified at 140r / min, washed with pure water after modification, modified bentonite particles 2.

Embodiment 3

[0042] 1) Mix bentonite and starch in a weight ratio of 100:3, add water and mix evenly to form small balls with a particle size of 4mm, dry the small balls at a constant temperature of 100 degrees Celsius for 2 hours, and dry them at 500 degrees Celsius Calcined for 5h to make granular adsorbent.

[0043] 2) The granular adsorbent that 5g of step 1) is obtained is modified in the calcium chloride solution that the concentration of 100mL is 0.10mol / L, and the modification process is carried out in the shaker, and the modification time is 40min, and the shaker speed is Modified at 120r / min, washed with pure water after modification, and modified bentonite particles 3 were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com