Electrical equipment inspection system with good anti-electromagnetic radiation performance

A technology for preventing electromagnetic radiation and power equipment, applied in the field of power equipment, can solve problems such as inconvenience in use, and achieve the effects of reducing interference, excellent shielding efficiency, and high magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

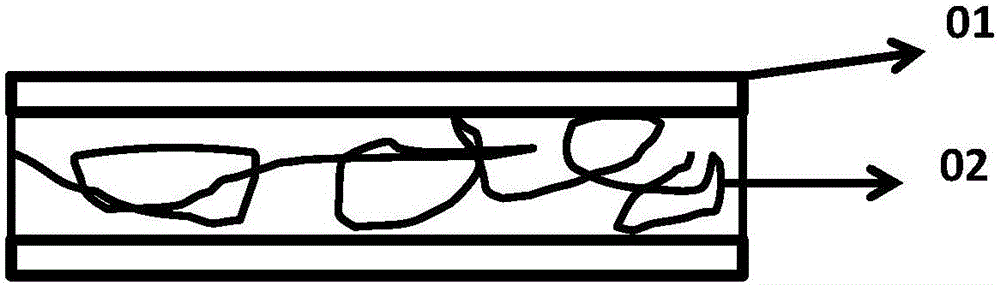

[0042] A power equipment inspection system with good performance in preventing electromagnetic radiation, the outer surface of the power equipment inspection system is covered with an electromagnetic shielding cover, and the cover is made of permalloy plate (01) and foamed aluminum-copper-nickel alloy (02 ) realizes the electromagnetic shielding function, and at the same time, the surface of the cover is treated with hydrochloric acid to form a superhydrophobic structure of nanosheets, which plays a role of self-cleaning and anti-corrosion protection.

[0043] The cover body is a sandwich structure, specifically two layers of permalloy plates (01) sandwiching a layer of foamed aluminum-copper-nickel alloy (02); the thickness of the permalloy plate (01) is 0.5mm, the The surface of the permalloy plate (01) is covered by a nanosheet structure; the ratio of Ni and Fe in the permalloy plate (01) is 2:3, and the mass fractions of 0.5% and 1% of Mo and Si elements are added The thic...

Embodiment 2

[0068] A power equipment inspection system with good performance in preventing electromagnetic radiation, the outer surface of the power equipment inspection system is covered with an electromagnetic shielding cover, and the cover is made of permalloy plate (01) and foamed aluminum-copper-nickel alloy (02 ) realizes the electromagnetic shielding function, and at the same time, the surface of the cover is treated with hydrochloric acid to form a superhydrophobic structure of nanosheets, which plays a role of self-cleaning and anti-corrosion protection.

[0069] The cover body is a sandwich structure, specifically two layers of permalloy plates (01) sandwiching a layer of foamed aluminum-copper-nickel alloy (02); the thickness of the permalloy plate (01) is 0.5mm, the The surface of the permalloy plate (01) is covered by a nanosheet structure; the ratio of Ni and Fe in the permalloy plate (01) is 2:3, and the mass fractions of 0.5% and 1% of Mo and Si elements are added The thic...

Embodiment 3

[0094] A power equipment inspection system with good performance in preventing electromagnetic radiation, the outer surface of the power equipment inspection system is covered with an electromagnetic shielding cover, and the cover is made of permalloy plate (01) and foamed aluminum-copper-nickel alloy (02 ) realizes the electromagnetic shielding function, and at the same time, the surface of the cover is treated with hydrochloric acid to form a superhydrophobic structure of nanosheets, which plays a role of self-cleaning and anti-corrosion protection.

[0095] The cover body is a sandwich structure, specifically two layers of permalloy plates (01) sandwiching a layer of foamed aluminum-copper-nickel alloy (02); the thickness of the permalloy plate (01) is 0.5mm, the The surface of the permalloy plate (01) is covered by a nanosheet structure; the ratio of Ni and Fe in the permalloy plate (01) is 2:3, and the mass fractions of 0.5% and 1% of Mo and Si elements are added The thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com