Nitrogen and sulfur codoped porous carbon prepared from direct coal liquefaction heavy organic matter and preparing method and application thereof

A technology of direct coal liquefaction and nitrogen-sulfur co-doping, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of limited selection range and high cost of nitrogen source and sulfur source, and achieve excellent electrocatalytic performance , the effect of excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

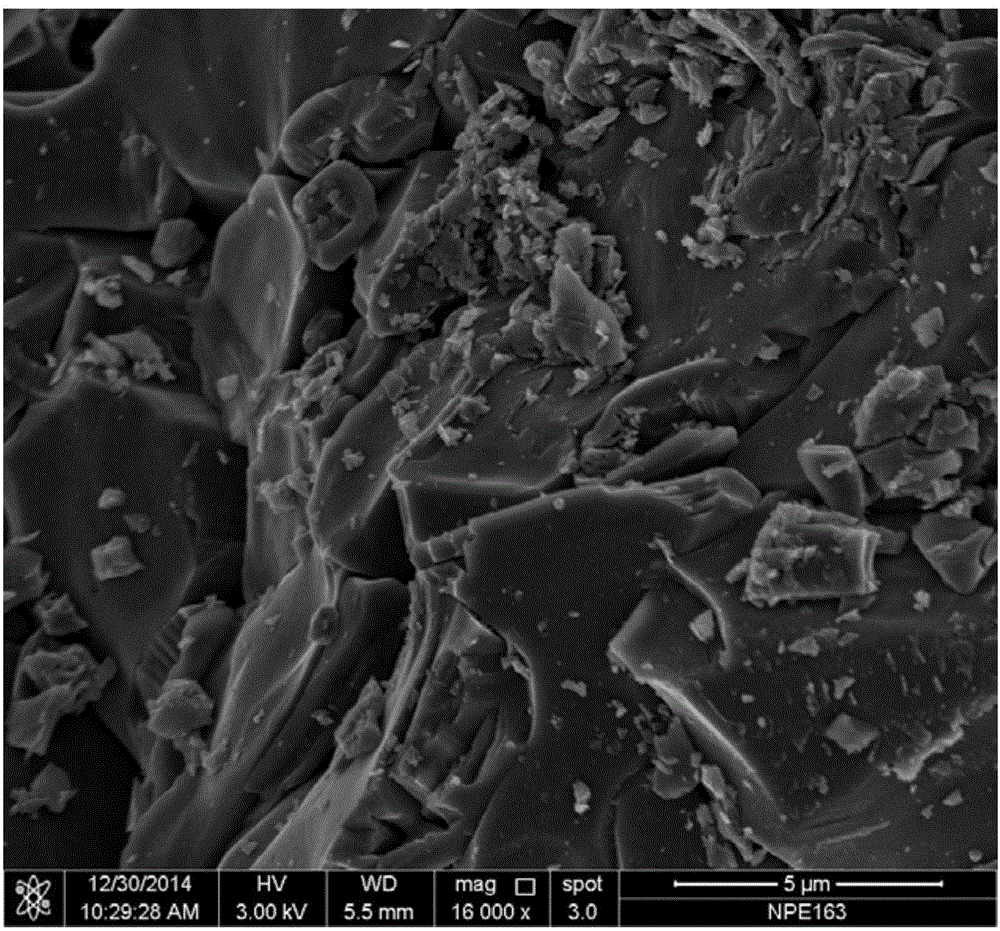

Embodiment 1

[0034] 10 g of ground coal direct liquefaction heavy organic matter was sulfonated in 200 g of 90% concentrated sulfuric acid at 100° C. for 15 h to obtain the first hydrophilic product. Take 0.5g of the first product and add it to a saturated solution of thiourea with a thiourea content of 1g, then add 5.5g of formaldehyde solution (37wt%), react at 100°C for 10min, and dry at 100°C to remove moisture to obtain the second product. Get the second product 1g and mechanically mix 5g magnesium citrate, it is placed in the carbonization furnace, at 200mLmin -1 Ar atmosphere, at 2°C min -1 The temperature was raised from room temperature to 490°C at a rate of 1h, and then at 5°C min -1 The rate is raised from 490°C to 700°C, kept for 1h, and then at 200mLmin -1 Cooled to room temperature under an Ar atmosphere, the resulting mixture was washed with 1M HCl to remove magnesium oxide, filtered, the filter cake was washed with water until the filtrate was close to neutral, and the fi...

Embodiment 2

[0036] 10 g of ground coal direct liquefaction heavy organic matter was sulfonated in 200 g of 98% concentrated sulfuric acid at 180° C. for 1 h to obtain the first hydrophilic product. Take 1.5g of the first product and add it to a saturated solution of thiourea with a thiourea content of 1g, then add 1.5g of formaldehyde solution (37wt%), react at 150°C for 1min, and dry at 100°C to remove moisture to obtain the second product. Get the second product 1g and 6g magnesium oxalate (or magnesium citrate) mechanically mixed, it is placed in the carbonization furnace, in 200mLmin -1 Ar atmosphere, at 2°C min -1 The rate is raised from room temperature to 490°C, kept for 30min, and then at 5°Cmin -1 The rate is raised from 490°C to 800°C, kept for 7h, and then at 200mLmin -1 Cooled to room temperature under an Ar atmosphere, the resulting mixture was washed with 1M HCl to remove magnesium oxide, filtered, the filter cake was washed with water until the filtrate was close to neutr...

Embodiment 3

[0038] 10 g of ground coal directly liquefied heavy organic matter in 180 g of fuming sulfuric acid (15 wt% SO 3 ) at 40°C for 24h to obtain the first hydrophilic product. Take 1g of the first product and add it to a saturated solution of thiourea with a thiourea content of 1g, then add 4g of formaldehyde solution (37wt%), react at 50°C for 1h, and dry at 100°C to remove moisture to obtain the second product. Get the second product 1g and mechanically mix 5g magnesium citrate, it is placed in the carbonization furnace, at 200mLmin -1 Under nitrogen atmosphere, at 1°C min -1 The temperature was raised from room temperature to 490°C at a rate of 1h, and then at 5°C min -1 The rate is raised from 490°C to 900°C, kept for 3h, and then at 200mLmin -1 Cooled to room temperature under a nitrogen atmosphere, the resulting mixture was washed with 1M HCl to remove magnesium oxide, filtered, the filter cake was washed with water until the filtrate was close to neutral, and the filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com