Treatment method and equipment for up-to-standard discharging of vitamin fermentation pharmaceutical wastewater

A technology for pharmaceutical wastewater and vitamins, applied in biological water/sewage treatment, water/sewage treatment, natural water treatment, etc., can solve problems such as high cost, increased process section, and inability to meet denitrification needs, etc., to achieve removal Excellent refractory COD, reduced infrastructure and operating costs, and improved bioretention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

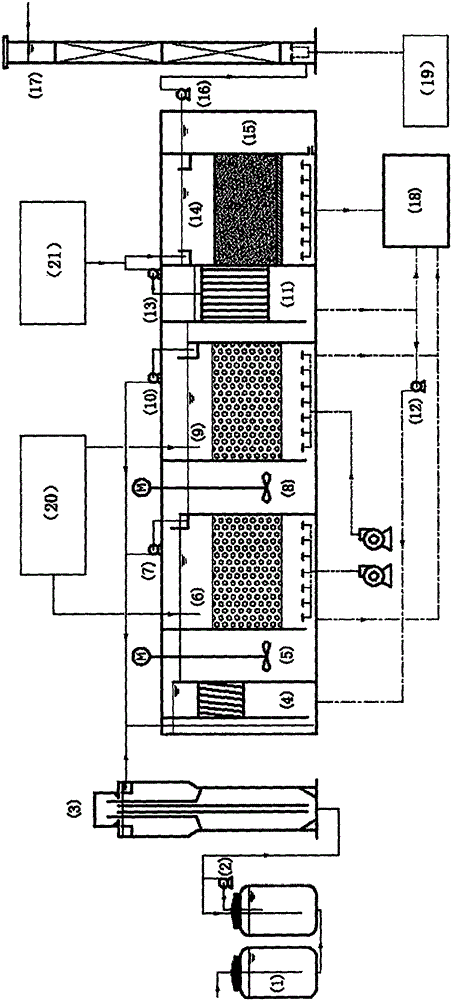

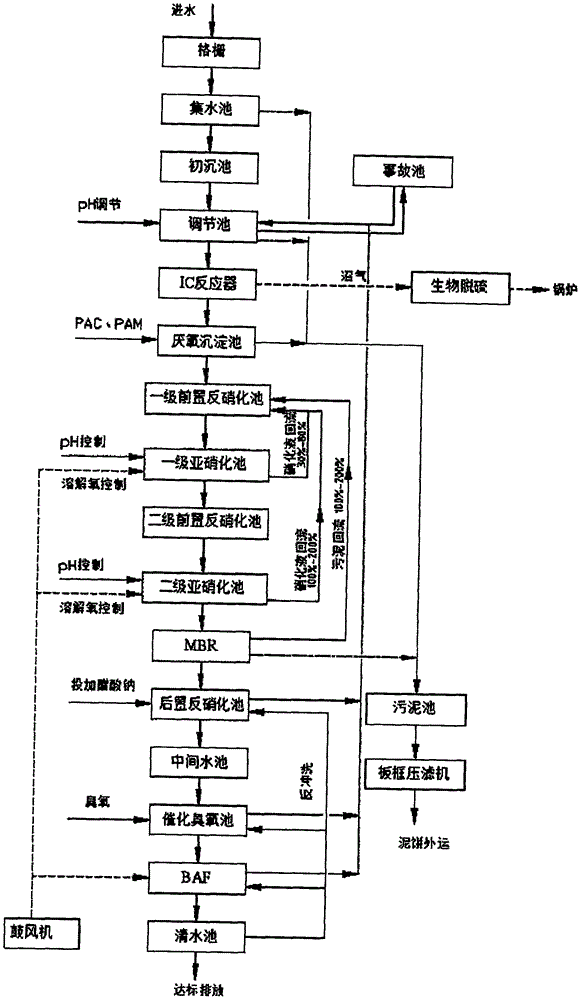

[0038] Such as Figure 1 to Figure 5 Shown, a kind of treatment method and equipment of the present invention's vitamin fermentation pharmaceutical waste water up to standard discharge, its equipment comprises: the water inlet barrel (1), IC reactor (3), primary settling tank (4) connected successively by delivery pipeline ), D1 pool (5), N1 pool (6), D2 pool (8), N2 pool (9), MBR pool (11), D3 pool (14), intermediate pool (15), catalytic ozone oxidation tower (17 ).

[0039] The top of the water inlet barrel (1) is provided with an anaerobic lifting pump (2); the top of the N1 pool (6) is provided with a primary nitrifying liquid return pump (7); the top of the N2 pool (9) is provided with Secondary nitrifying liquid return pump (10); The sludge return pump (12) is provided between the described primary settling tank (4) and the sludge pond (18); The top of the described MBR pond (11) is provided with the MBR automatic Suction pump (13); Catalytic ozone lifting pump (16) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com