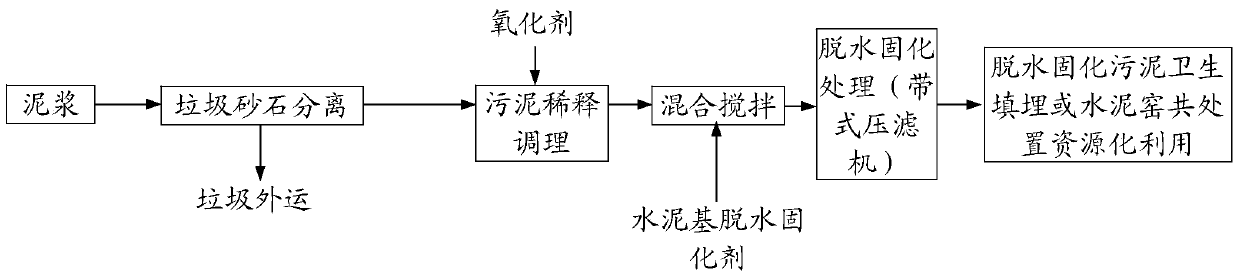

A kind of treatment method for dilution, conditioning and solidification of non-standard disposal sludge

A treatment method and sludge technology, applied in sludge treatment, fixed/solidified sludge treatment, water/sludge/sewage treatment, etc., can solve difficult mixing, hinder cement hydration reaction, and reduce sludge solidification treatment Effect and other issues, to achieve the effect of improving efficiency, reducing sludge viscosity, and promoting fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

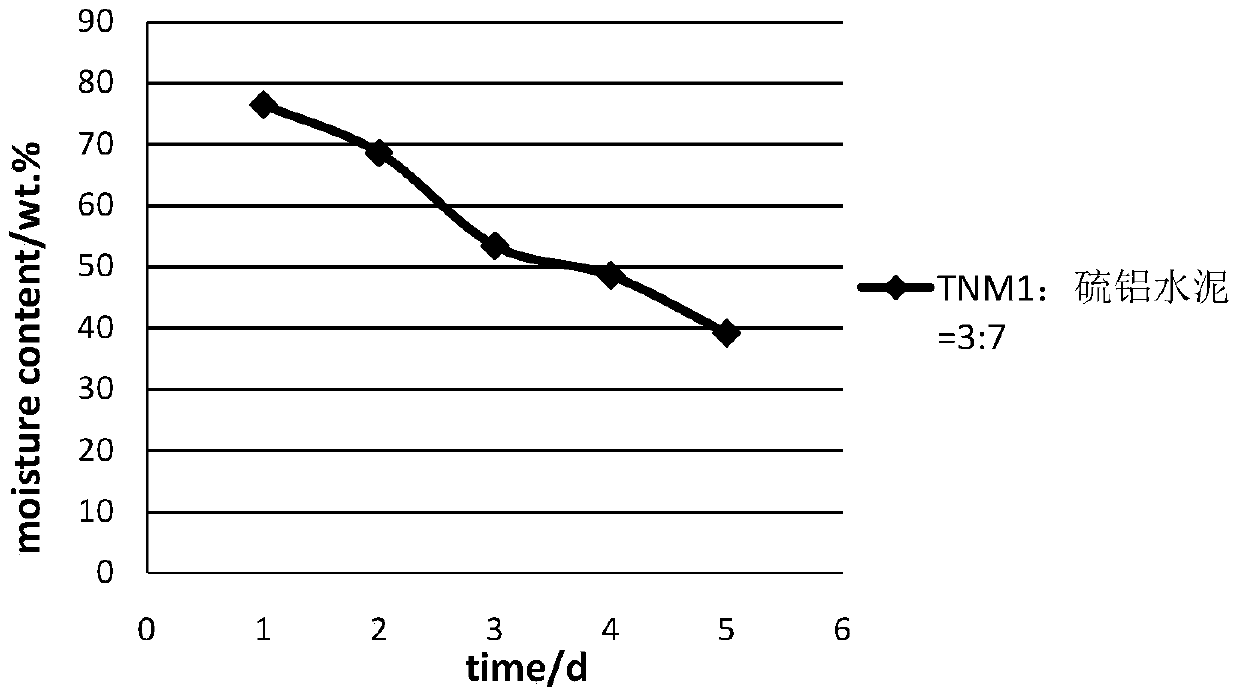

[0041] Example 1 - Dehydration and solidification of sludge in an open-air storage pit of a waste landfill in Xi'an

[0042] (1) Preparation of aluminum-based gelling and curing agent

[0043] The laboratory preparation method adopts the falling cone method: grind the TNM1 type dehydration curing agent and sulfur-aluminum cement with a mass ratio of 3:7, pass through a 0.08mm sieve, mix and pile up into a cone shape, and then flatten it, and pile up the surrounding samples toward the center again After the cone is formed, it is flattened, and this is repeated several times to obtain a cement-based mixed dehydration curing agent;

[0044] Prepare 150 g of aluminum-based gelling and curing agent as described above.

[0045] (2) Solidification and modification treatment of sludge to be disposed of

[0046] The analysis results of the basic properties of the sludge to be disposed are shown in Table 1.

[0047] Table 1 Analysis results of basic properties of sludge

[0048] ...

Embodiment 2

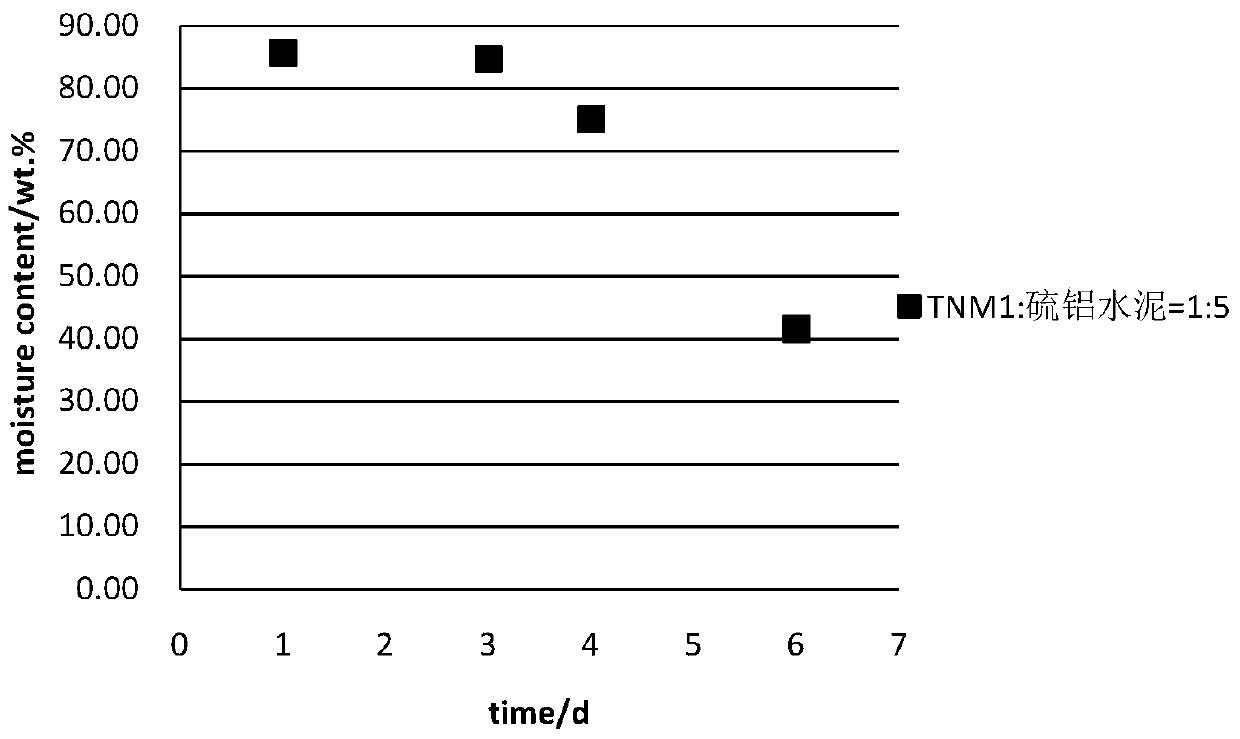

[0054] Example 2 - Dehydration and solidification of sludge in an open-air storage pit of a waste landfill in Xi'an

[0055] (1) Preparation of aluminum-based gelling and curing agent

[0056] The laboratory preparation method adopts the falling cone method: grind the TNM1 type dehydration curing agent and sulfur-aluminum cement with a mass ratio of 1:5, pass through a 0.08mm sieve, mix and pile up into a cone shape, and then flatten it, pile up the surrounding samples toward the center again After the cone is formed, it is flattened, and this is repeated several times to obtain a cement-based mixed dehydration curing agent;

[0057] Prepare 150 g of aluminum-based gelling and curing agent as described above.

[0058] (2) Solidification and modification treatment of sludge to be disposed of

[0059] The analysis results of the basic properties of the sludge to be disposed are shown in Table 2.

[0060] Table 2 Analysis results of basic properties of sludge

[0061]

[0...

Embodiment 3

[0067] Example 3 - Dehydration and solidification of sludge in an open-air storage pit of a waste landfill in Xi'an

[0068] (1) Preparation of aluminum-based gelling and curing agent

[0069] The laboratory preparation method adopts the falling cone method: grind the TNM1 dehydration curing agent and sulfur-aluminum cement with a mass ratio of 2:6, pass through a 0.08mm sieve, mix and pile up into a conical shape, then flatten, and pile up the samples around the center again After the cone is formed, it is flattened, and this is repeated several times to obtain a cement-based mixed dehydration curing agent;

[0070] Prepare 150 g of aluminum-based gelling and curing agent as described above.

[0071] (2) Solidification and modification treatment of sludge to be disposed of

[0072] The analysis results of the basic properties of the sludge to be disposed are shown in Table 3.

[0073] Table 3 Analysis results of basic properties of sludge

[0074]

[0075] Take the 300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com