Quaternary ammonium salinization fluorescence silicon dot and preparation method and application thereof

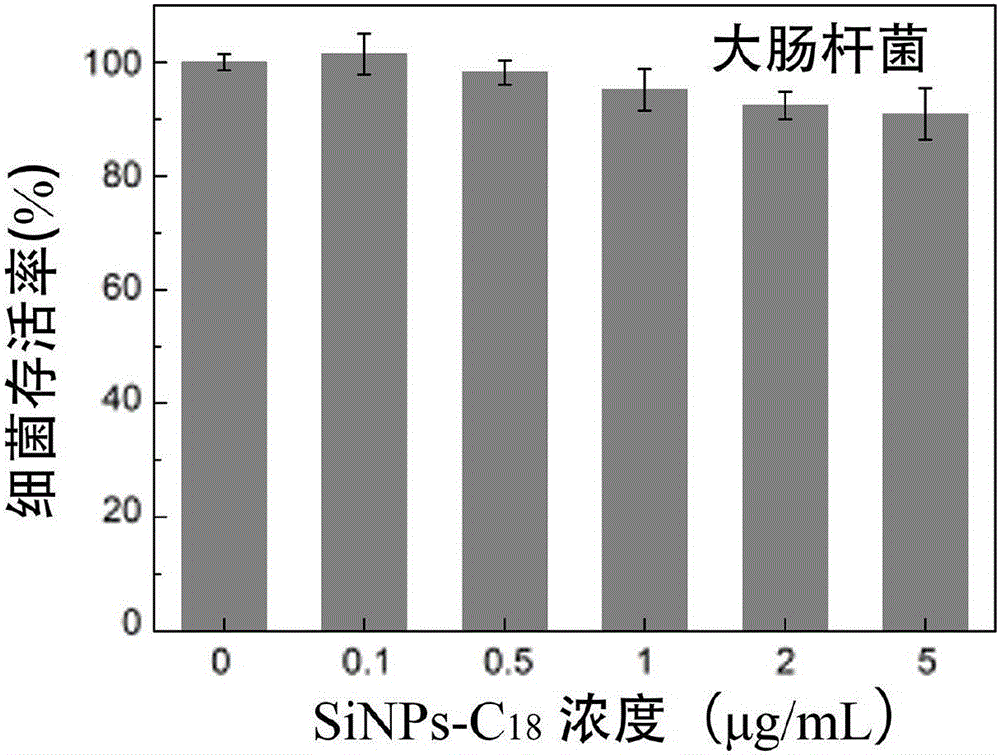

A quaternary ammonium saltization and fluorescence technology, which is applied in chemical instruments and methods, luminescent materials, organic chemistry, etc., can solve the problems of low bacterial imaging discrimination, drug resistance and antibacterial applications, and low biocompatibility. Good stability, guaranteed safety, and low cytotoxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

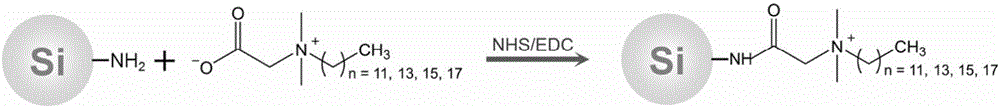

Method used

Image

Examples

Embodiment 1

[0046] The preparation of the water-soluble silicon dots with amino groups on the surface comprises the following steps:

[0047] (1) Be that the mass fraction is 4.65% sodium citrate aqueous solution, pass into nitrogen 5min, remove the oxygen in the solution;

[0048] (2) Add 3-aminopropyl-trimethoxysilane (APTMS) while stirring in the sodium citrate aqueous solution after deoxygenation, and continue stirring for 10 min in a closed state to form a silicon dot precursor solution; APTMS and lemon The mass ratio of the solute sodium citrate in the sodium citrate aqueous solution is 1:4;

[0049] (3) React the mixed system obtained in step (2) at 180° C. for 5 minutes in a microwave reactor to form a silicon dot solution;

[0050] (4) Use a dialysis bag with a molecular weight of 1000 (the dialysate is water) to dialyze the silicon dot solution to obtain pure APTMS silicon dot solution.

Embodiment 2

[0052] The preparation method is the same as that of Example 1, except that in step (3), the reaction temperature is 140° C., and the reaction time is 15 minutes.

Embodiment 3

[0054] The preparation method is the same as in Example 1, except that in step (2), 3-aminopropyl-triethoxysilane (APTES), 3-(2-aminoethylamino)propyltrimethoxy 3-aminopropyl-trimethoxysilane (DAMO) and 3-[2-(2-aminoethylamino) ethylamino] propyltrimethoxysilane (AEEA) respectively replace embodiment 1 APTMS), prepared three different water-soluble silicon dots with amino groups; the mass ratio of organosilane and reducing agent was 1:8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Minimum inhibitory concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com