Method for removing keratan sulfate from chondroitin sulfate crude extract

A technology for chondroitin sulfate and keratan sulfate, applied in the biological field, can solve the problems of difficult industrial production, difficulty in removing keratan sulfate, etc., achieves the effects of simple operation, solving the difficulty in removing keratan sulfate, and saving usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

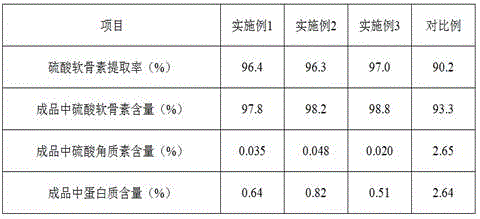

Embodiment 1

[0021] Taking the chondroitin sulfate crude extract and adding deionized water to prepare 10L mass fraction is a solution of 10%, the conductivity of the solution is 20ms / cm, wherein the chondroitin sulfate content is 90% in the crude extract, and the content of keratan sulfate is 2%, the protein content is 1%,. Use 2moL / L sodium hydroxide solution to adjust the pH to 12, stir at room temperature for 2 hours, then adjust the pH to 8 with hydrochloric acid, raise the temperature to 45°C, keep it warm for 3 hours, lower to room temperature, adjust the pH of the solution to 6 with hydrochloric acid, and filter to obtain the filtrate. Add solid sodium chloride to the filtrate to adjust the conductivity of the solution to 45ms / cm, and add 95% ethanol solution very slowly to the solution with adjusted conductivity, control the flow rate to 15mL / (L·min), and continuously Stir until the alcohol content of the solution is 50%, let it stand for 2 hours, filter to obtain a precipitate, d...

Embodiment 2

[0023] Taking the chondroitin sulfate crude extract and adding deionized water to prepare 10L mass fraction is a solution of 15%, the conductivity of the solution is 22ms / cm, wherein the chondroitin sulfate content is 92% in the crude extract, and the content of keratan sulfate is 4%, and the protein content is 3%. Use 2moL / L sodium hydroxide solution to adjust the pH to 14, stir at room temperature for 3 hours, then adjust the pH to 9 with hydrochloric acid, raise the temperature to 50°C, and keep it warm for 4 hours, then lower the temperature to room temperature and adjust the pH of the solution to 7 with hydrochloric acid, and filter to obtain the filtrate. Add solid sodium chloride to the filtrate to adjust the conductivity of the solution to 48ms / cm, and add absolute ethanol solution to the solution with adjusted conductivity very slowly, control the flow rate to 10mL / (L min), and keep stirring, Until the alcohol content of the solution is 55%, let it stand for 4 hours, ...

Embodiment 3

[0025] Taking the chondroitin sulfate crude extract and adding deionized water to prepare 10L mass fraction is a solution of 15%, the conductivity of the solution is 21ms / cm, wherein the chondroitin sulfate content is 90% in the crude extract, and the content of keratan sulfate is 2%, protein content is 1%. Use 2mol / L sodium hydroxide solution to adjust the pH to 14, stir at room temperature for 3 hours, then adjust the pH to 9 with hydrochloric acid, raise the temperature to 50°C, and keep it warm for 4 hours, then lower to room temperature and adjust the pH of the solution to 6 with hydrochloric acid, filter, and then filter Add solid sodium chloride to the solution to adjust the conductivity of the solution to 46ms / cm, add absolute ethanol solution to the solution with adjusted conductivity very slowly, control the flow rate to 13mL / (L·min), and keep stirring until The alcohol content of the solution is 55%, let it stand for 4 hours, and filter to obtain the precipitate, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com