High molecular antistatic agent and preparation method thereof

An antistatic agent and polymer-based technology, which is used in the field of polymer antistatic agents and their preparation, can solve the problems of insufficient compatibility, low processability, low density, and poor heat resistance of anionic antistatic agents. Achieve the effect of excellent compatibility and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

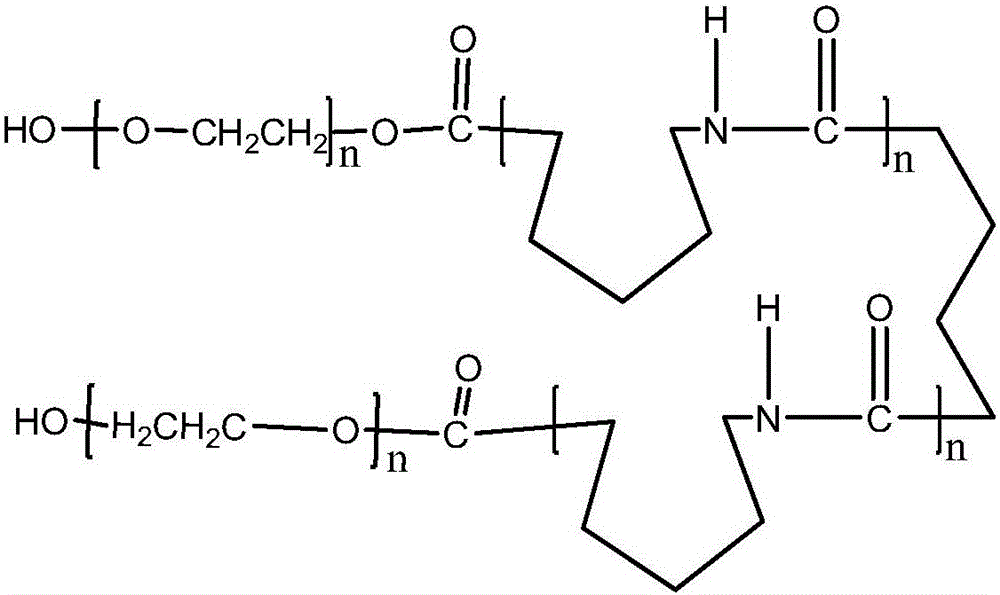

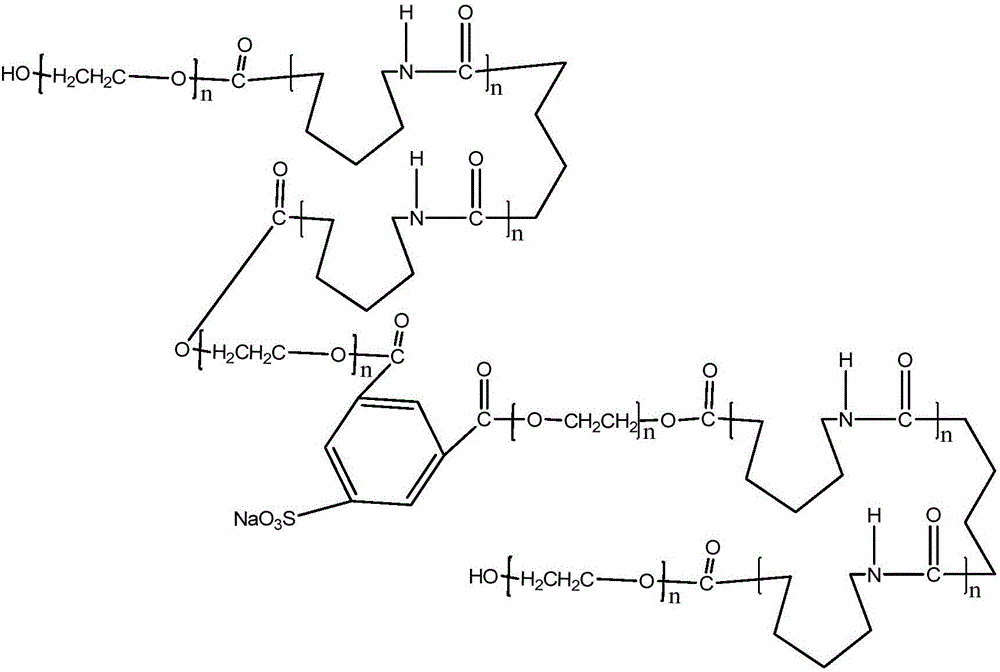

[0027] The synthetic route of the present embodiment is as follows:

[0028]

[0029] 10 molar parts of 5-sodium isophthalic acid (5-SSIPA), 28 molar parts of polyethylene glycol (PEG) and 10 molar parts of methanesulfonic acid were mixed and heated to 100 ° C for 1 h. Na after reaction 2 CO 3 Neutralize, precipitate with ethanol, and dry the product to obtain dipolyethylene glycol isophthalate-5-sodium sulfonate. Mix with polypropylene (PP) according to the mass ratio of dipolyethylene glycol isophthalate-5-sodium sulfonate / polypropylene as 5%, 10%, 15%, and 20%, and knead in an open mixer , Tablets were pressed in a vulcanizing machine, and the surface resistance and volume resistance were tested at 25°C and 40% humidity. The results are shown in Table 1.

[0030] Table 1

[0031]

[0032] Table 1 shows that after adding the above-mentioned antistatic agent, the volume resistance and surface resistance of polypropylene are significantly reduced, and it has excellen...

Embodiment 2

[0034] 10 molar parts of 5-sodium isophthalic acid (5-SSIPA), 28 molar parts of polyethylene glycol (PEG) and 10 molar parts of methanesulfonic acid were mixed and heated to 120 ° C for 1 h. Na after reaction 2 CO 3 Neutralize, precipitate with ethanol, and dry the product to obtain dipolyethylene glycol isophthalate-5-sodium sulfonate. Mix with polypropylene (PP) according to the mass ratio of dipolyethylene glycol isophthalate-5-sodium sulfonate / polypropylene as 5%, 10%, 15%, and 20%, and knead in an open mixer , Tablets were pressed in a vulcanizing machine, and the surface resistance and volume resistance were tested at 25°C and 40% humidity. Dipolyethylene glycol isophthalate-5-sodium sulfonate prepared in this example also has excellent antistatic properties, see Example 1 for specific results.

Embodiment 3

[0036] Mix 10 molar parts of 5-sodium isophthalic acid-5-sulfonate (5-SSIPA), 28 molar parts of polyethylene glycol (PEG) and 10 molar parts of methanesulfonic acid, then heat to 120°C for 2 hours, Na after reaction 2 CO 3 Neutralize, precipitate with ethanol, and dry the product to obtain dipolyethylene glycol isophthalate-5-sodium sulfonate. Mix with polypropylene (PP) according to the mass ratio of dipolyethylene glycol isophthalate-5-sodium sulfonate / polypropylene as 5%, 10%, 15%, and 20%, and knead in an open mixer , Tablets were pressed in a vulcanizing machine, and the surface resistance and volume resistance were tested at 25°C and 40% humidity. Dipolyethylene glycol isophthalate-5-sodium sulfonate prepared in this example also has excellent antistatic properties, see Example 1 for specific results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com