A wood-aluminum alloy tube composite column and its manufacturing method

A technology of aluminum alloy tubes and manufacturing methods, applied in the direction of columns, pillars, pier columns, etc., can solve the problems of easy corrosion, easy combustion, wood vulnerable to insects, etc., achieve excellent mechanical properties, improve bearing capacity, and delay local buckling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A method for preparing a wood-aluminum alloy tube composite column, the specific manufacturing steps include the following:

[0041]1) Select the material type and cross-sectional size of the wooden column according to the design requirements, and carry out the defect inspection of the wood, and choose the wood with less defects for the small-sized composite column;

[0042] 2) Dry the formed wooden column and control its moisture content to not exceed the equilibrium moisture content of the environment. By controlling the moisture content of the wood, the composite column will not continue to shrink in the environment after being formed, which will affect the restraining effect of the aluminum alloy tube on the core wooden column. However, even if there is a tendency to absorb water and expand when encountering a water environment, due to the restraining effect of the aluminum alloy tube on the core column, no adverse consequences will be produced at this time.

[004...

Embodiment 1

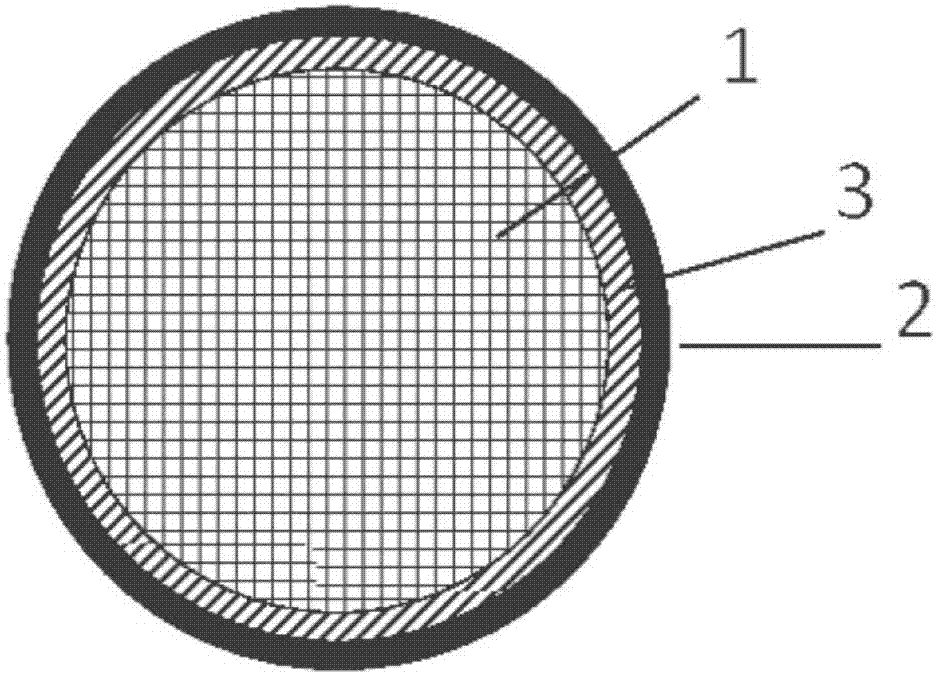

[0049] The combined column of this embodiment is a circular section (such as figure 1 ), the aluminum alloy round tube 2 is used, the outer diameter of the tube is 220mm, the wall thickness of the tube is 5mm, the length of the tube is 3000mm, which is the same as the length of the column, and the aluminum alloy material is 6082-T4.

[0050] The core wooden column 1 has a length of 3000 mm, an outer diameter of 160 mm, and a gap of 30 mm between the wooden column and the aluminum alloy tube, which can be used for the construction of the self-compacting expansive cement mortar 3 used in the combined column of this embodiment.

[0051] The circular wooden column is preferably made of wood with few defects, and then the wooden column is dried to reduce the moisture content of the wood to below the environmental equilibrium moisture content. If the local environmental equilibrium moisture content is 17%, the moisture content of the wood cannot be controlled. exceed this value. Af...

Embodiment 2

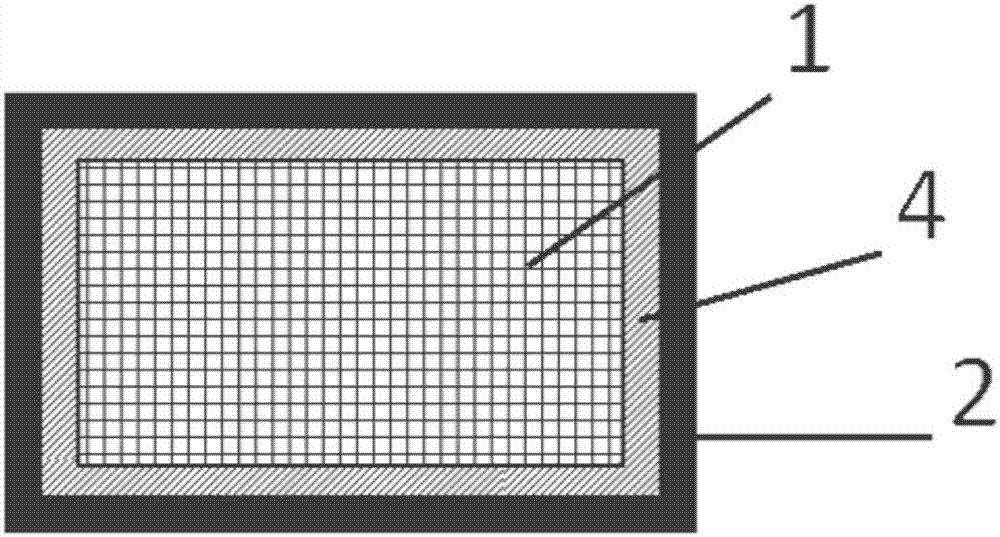

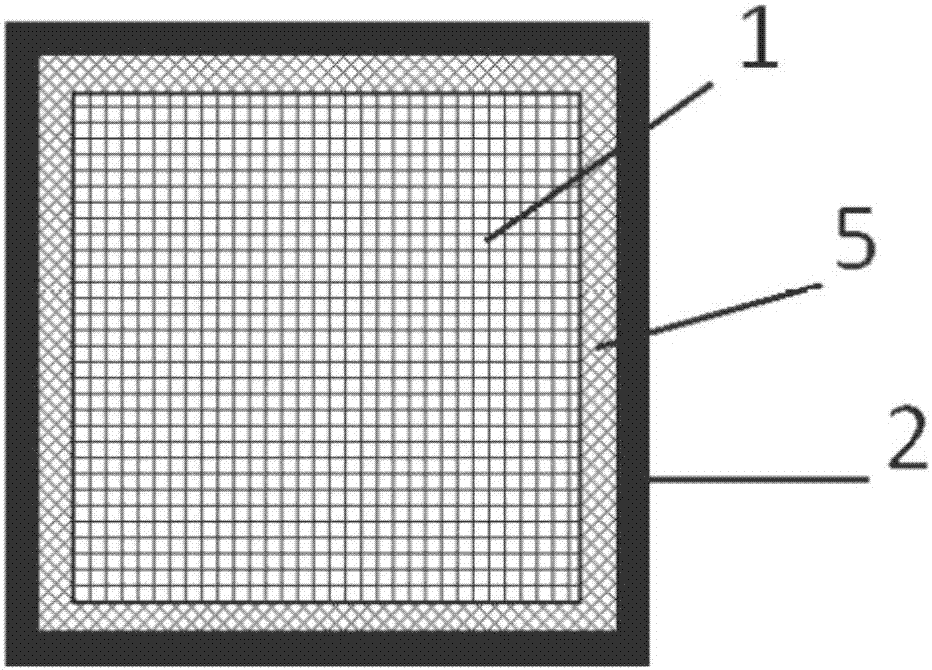

[0056] The combined column of this embodiment is a square section (such as image 3 ), using aluminum alloy square tube 2, the outer length of the square tube is 120mm, the wall thickness of the tube is 3.5mm, the tube length is 1500mm the same as the column length, and the aluminum alloy material is 5083-H12.

[0057] The core wooden column 1 is square, the side length is 90 mm, the length of the wooden column is 1500, and the gap between the wooden column and the aluminum alloy tube is 15 mm.

[0058] The material selection and processing of the square wooden column are the same as in Example 1. However, in this embodiment, the structural glue 5 is used as the filling material, and there is no need to perform waterproof treatment on the surface of the wood.

[0059] Place the wooden column in the aluminum alloy tube, and place four wooden wedges in the gap between the aluminum alloy tube and the wooden column at both ends to maintain the relative position between the alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com