Material design method for elastic copper alloy

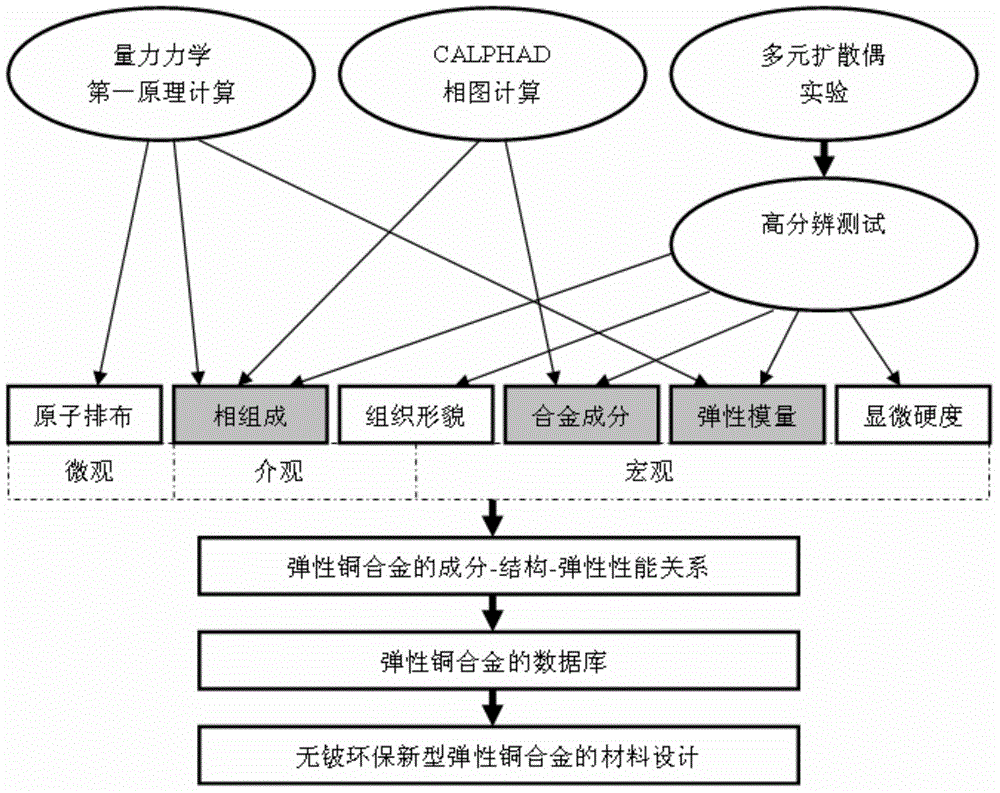

A technology of elastic copper alloy and design method, applied in the direction of calculation, special data processing application, instrument, etc., can solve the problems of narrow alloy composition range, difficulty in obtaining experimental data, inability to systematically and accurately find the influence law of added elements, etc. The effect of saving time, easy implementation, saving R&D cost and R&D efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

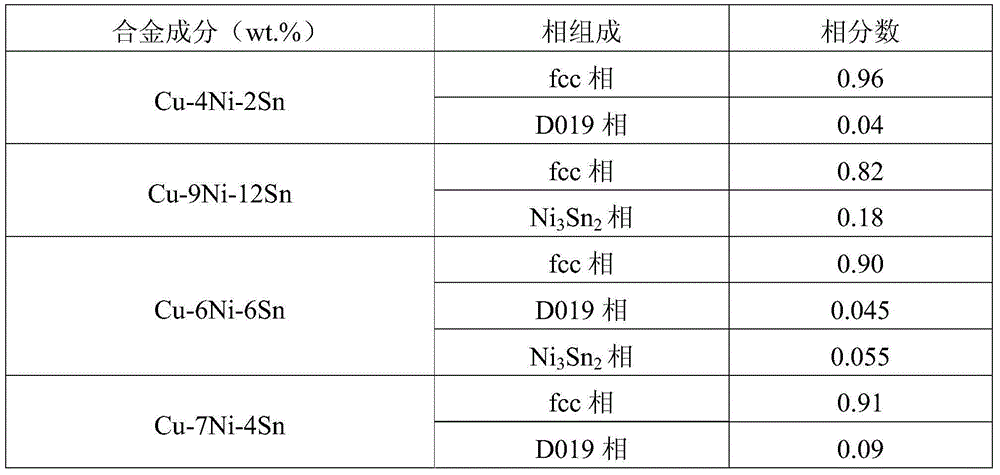

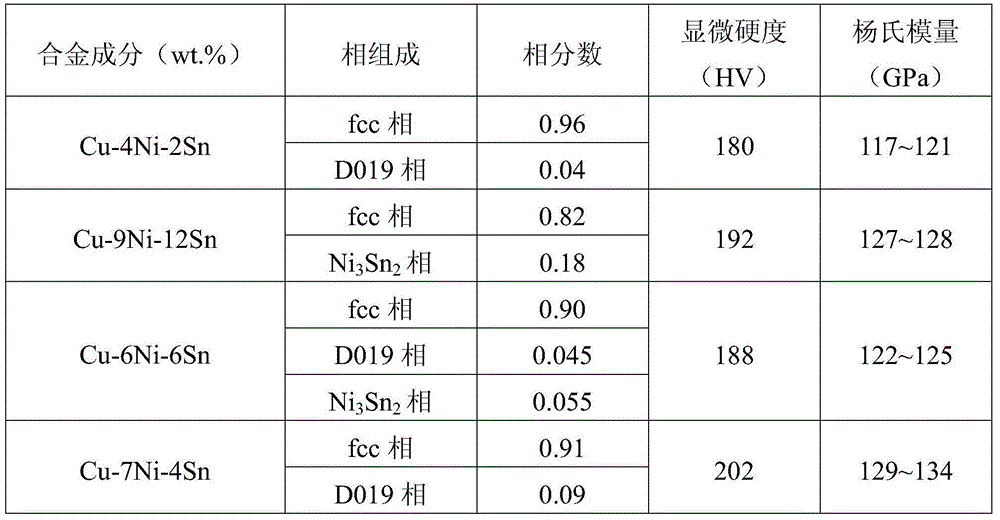

[0035] The target research system is Cu-Ni-Sn elastic copper alloy. Firstly, the thermodynamic model of the Cu-Ni-Sn ternary system is established, and at 300°C, it is quickly obtained by calculation:

[0036]

[0037] According to the first principle calculation of quantum mechanics, the stable phases of the Cu-Ni-Sn system include: liquid, fcc, bcc, hcp, B2, Cu 3 Sn, Cu 41 sn 11 、Cu 6 sn 5 、Cu 10 sn 3 , D019, Ni 3 sn 2 、Ni 3 sn 4 、Ni 3 Sn. Combined with the calculation results of the phase diagram, the Young's moduli of the four alloys listed in the above table are calculated to be 117GPa, 128GPa, 122GPa and 129GPa at 300°C.

[0038] Melting pure Cu, pure Ni, Cu-20Sn alloy to prepare Cu-Ni-Sn multi-component diffusion couple. With a vacuum of 1.2×10 -3 The vacuum quartz tube of Pa was sealed, heat treated at 300°C for 700 hours, and samples were taken after quenching. Using EPMA, EBSD, and nano-indentation high-resolution test methods to analyze the metal i...

Embodiment 2

[0044] The target research system is Cu-Ti-Sn elastic copper alloy. Firstly, the thermodynamic model of the Cu-Ti-Sn ternary system is established, and at 300°C, 400°C and 500°C, the following calculations are quickly obtained:

[0045]

[0046] Through the first principle calculation of quantum mechanics, the stable phases of the Cu-Ti-Sn system include: liquid, fcc, bcc, hcp, B2, Cu 2 Ti, Cu 3 Sn, Cu 3 Ti 2 、Cu 41 sn 11 、Cu 4 Ti, Cu 4 Ti 3 、Cu 6 sn 5 、Cu 10 sn 3 , D019, CuTi 3 , CuTi, Sn 3 Ti 2 , Sn 5 Ti 6 , SnTi 2 、Cu 2 SnTi, Ti 5 sn 3 Cu, CuSnTi. Combined with the phase diagram calculation results, the Young's moduli of the 12 alloys listed in the above table are calculated as: 125GPa, 147GPa, 146GPa and 179GPa at 300°C; 136GPa, 120GPa, 168GPa and 107GPa at 400°C; 500 Under the condition of ℃, 112GPa, 115GPa, 149GPa and 163GPa

[0047] Melting pure Cu, pure Ti, Cu-30Sn alloy to prepare Cu-Ni-Sn multi-component diffusion couple. With a vacuum of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com