Cable capable of emitting light

A cable and cable core technology, applied in the field of luminous cables, can solve the problems of difficult identification, complex components, poor environmental protection, etc., and achieve the effect of easy identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

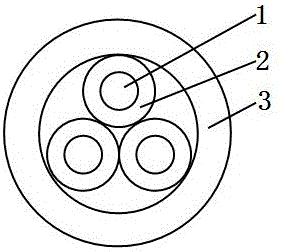

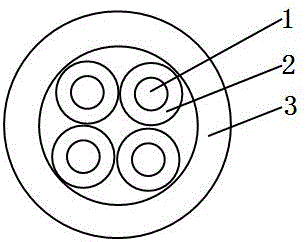

[0024] please see figure 1, a luminous cable, which is composed of a cable core and a sheath layer 3 coated outside the cable core. The insulating layer 2 is formed outside the conductor; the conductor is a copper conductor or an aluminum conductor or an aluminum-magnesium alloy conductor or a magnesium alloy conductor capable of conducting electricity, and the insulating layer is coated outside the conductor; it is characterized in that the sheath layer is in accordance with In parts by weight, it is composed of the following raw materials: low-density polyethylene or medium-density polyethylene or high-density polyethylene or low-smoke halogen-free flame-retardant polyethylene or low-smoke low-halogen flame-retardant polyethylene: 80-90 parts, market Red or yellow or green or brown or purple or blue or orange or purple or pink or turquoise polyethylene color masterbatch for sale: 4-6 parts, fineness less than 300 mesh transparent glass beads: 2-4 parts, fineness Colored flu...

Embodiment 2

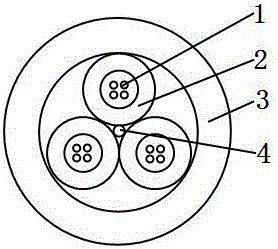

[0029] please see image 3 , a luminous cable, which is composed of a cable core and a sheath layer 3 wrapped outside the cable core. The cable core is composed of a reinforcement 4 and three insulated wires twisted around the reinforcement. Each insulation The wire is composed of an insulating layer 2 and a plurality of conductors 1 located in the insulating layer; the conductor is an optical fiber capable of transmitting signals, and the insulating layer constrains the conductor in the form of a tube, and there are gaps inside the insulating layer besides the conductor; It is characterized in that the sheath layer is composed of the following raw materials in parts by weight: low-density polyethylene or medium-density polyethylene or high-density polyethylene or low-smoke halogen-free flame-retardant polyethylene or low-smoke low-halogen flame-retardant polyethylene. Ethylene: 80-90 parts, commercially available red or yellow or green or brown or purple or blue or orange or ...

Embodiment 3

[0033] please see Figure 4 , a luminous cable, which is basically the same as in Example 2, except that: a marking strip 5 is inlaid on the sheath layer or the suspension wire sheath, and the marking strip is integrally formed with the sheath layer or the suspension wire sheath, The outer edge of the identification strip and the outer edge of the sheath layer are on the same cylindrical surface or the outer edge of the identification strip and the outer edge of the suspension wire sheath are on the same cylindrical surface.

[0034] Further, in this implementation example, the identification strip may be made of low-density polyethylene, medium-density polyethylene, high-density polyethylene, low-smoke halogen-free flame-retardant polyethylene or low-smoke low-halogen flame-retardant polyethylene; and the identification strip The main body material is consistent with the main body material of the sheath layer.

[0035] Further, in this implementation example, it is also poss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com