Surface modification method capable of improving surface lubricating property of anisotropic permanent magnet powder particles

A permanent magnet powder, anisotropic technology, applied in the manufacture of permanent magnets, magnetic materials, magnetic objects, etc., can solve problems such as increasing process costs, and achieve the effect of simplifying the production process, solving the problem of magnetic powder sticking to the wall, and having good magnetic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

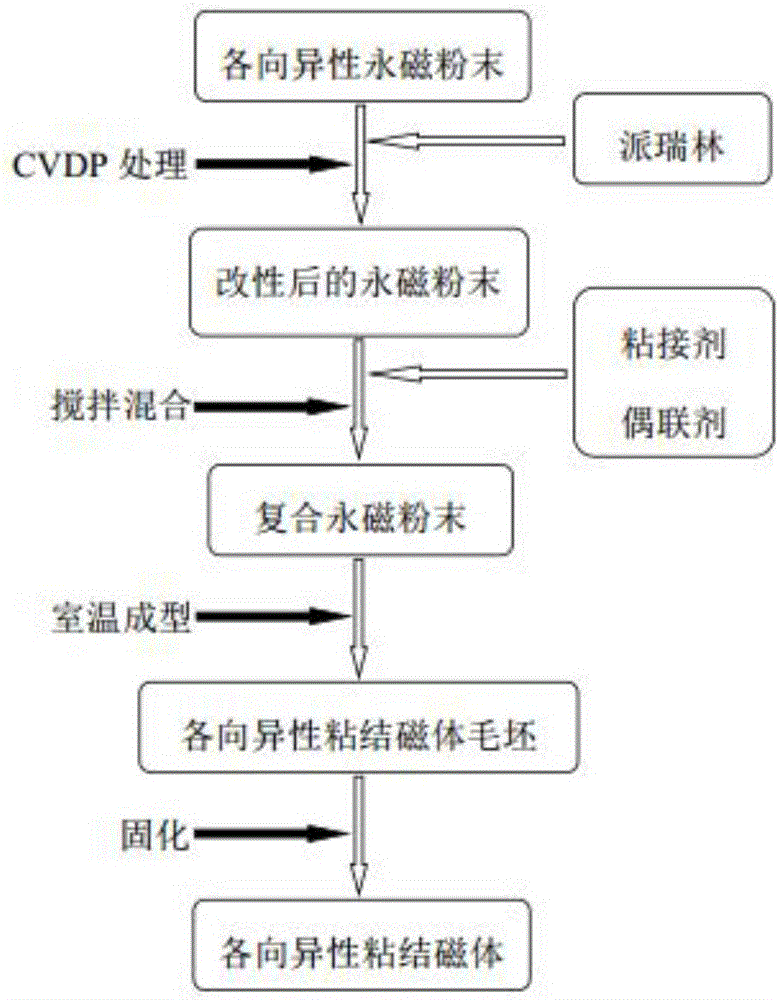

Method used

Image

Examples

Embodiment

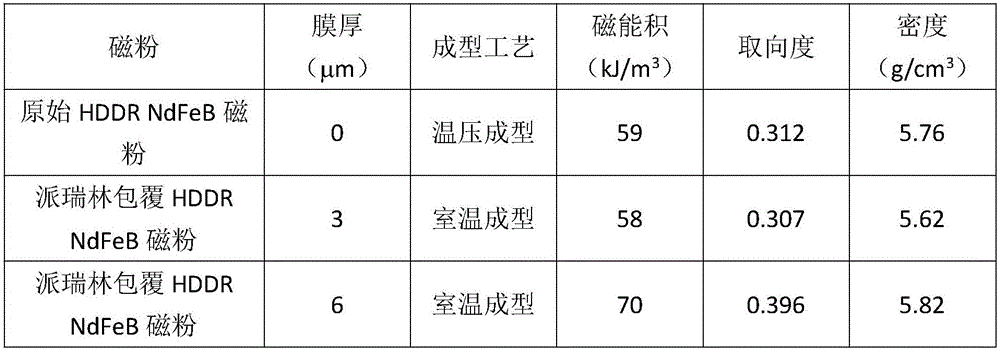

[0028] The permanent magnetic powder is HDDR anisotropic NdFeB magnetic powder and the powder particle size is less than 80 mesh, the thickness of the parylene film is ~3um, ~6um, the content of epoxy resin binder is 2.5% (mass fraction), and the content of silane coupling agent 0.5% (mass fraction).

[0029] The permanent magnet powder coated with parylene film is oriented at room temperature, and the process conditions are: the orientation magnetic field is 1.8T, and the pressing pressure is 600MPa.

[0030] The permanent magnet powder not coated with parylene film is formed by warm-press orientation. The process conditions are as follows: pressing temperature is 140°C, holding time is 1min, orientation magnetic field is 1.8T, and pressing pressure is 600MPa.

[0031] The performance comparison is shown in Table 1. Using the same HDDRNdFeB permanent magnet powder as raw material, using the same orientation magnetic field and pressing pressure, when the thickness of the pary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com