A kind of preparation method and application of copper-doped zinc lithium titanate nanoparticles

A technology of lithium zinc titanate and nanoparticles, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as poor lithium intercalation performance, achieve low cost, and improve lithium intercalation performance. Poor, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Dissolve 280 mg titanium isopropoxide in 570 mg citric acid to obtain titanium citrate solution;

[0021] 2) Control the temperature of the titanium citrate solution to 60 °C in a water bath, and then dissolve 25 mg lithium carbonate, 90 mg zinc nitrate hexahydrate and 3 mg copper nitrate trihydrate one by one;

[0022] 3) Add ethanol to the solution obtained in step 2) according to the weight ratio of ethanol to citric acid as 2:3, then raise the temperature of the solution to 80 °C, and take it out after reaching the sol state;

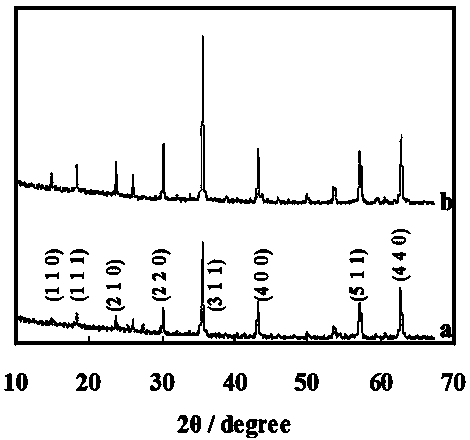

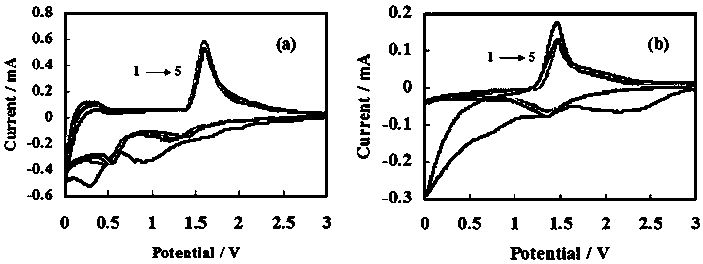

[0023] 4) Put the sol obtained in step 3) into a crucible, heat-treat at 350 °C for 1 h, then grind it into a powder state with an agate mortar, put it in a muffle furnace, and calcinate at 600 °C for 3 h to obtain copper-doped Lithium zinc titanate nanoparticles.

Embodiment 2

[0025] 1) Dissolve 300 mg titanium isopropoxide in 600 mg citric acid to obtain titanium citrate solution;

[0026] 2) Control the temperature of the titanium citrate solution to 75 °C in a water bath, and then dissolve 28 mg lithium carbonate, 110 mg zinc nitrate hexahydrate and 6 mg copper nitrate trihydrate one by one;

[0027] 3) Add ethanol to the solution obtained in step 2) according to the weight ratio of ethanol to citric acid as 2:3, then raise the temperature of the solution to 100 °C, and take it out after reaching the sol state;

[0028] 4) Put the sol obtained in step 3) into a crucible, heat-treat at 500 °C for 1 h, then grind it into a powder state with an agate mortar, put it in a muffle furnace, and calcinate it at 800 °C for 3 h to obtain copper doped Lithium zinc titanate nanoparticles.

Embodiment 3

[0030] 1) Dissolve 290 mg titanium isopropoxide in 580 mg citric acid to obtain titanium citrate solution;

[0031] 2) Control the temperature of the titanium citrate solution to 70 °C in a water bath, and then dissolve 26 mg lithium carbonate, 100 mg zinc nitrate hexahydrate and 4 mg copper nitrate trihydrate one by one;

[0032] 3) Add ethanol to the solution obtained in step 2) according to the weight ratio of ethanol to citric acid as 2:3, then raise the temperature of the solution to 90 °C, and take it out after reaching the sol state;

[0033] 4) Put the sol obtained in step 3) into a crucible, heat-treat at 400 °C for 1 h, then grind it into a powder state with an agate mortar, put it in a muffle furnace, and calcinate at 700 °C for 3 h to obtain copper doped Lithium zinc titanate nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com