Fuel cell, platinum-carbon catalyst and preparation method of platinum-carbon catalyst

A platinum carbon catalyst, fuel cell technology, applied in solid electrolyte fuel cells, battery electrodes, circuits, etc., can solve the problems of low platinum carbon catalyst preparation efficiency, large catalyst particle size, poor particle dispersion, etc., to overcome the catalyst layer. The effect of thickening, low fabrication cost, high platinum content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

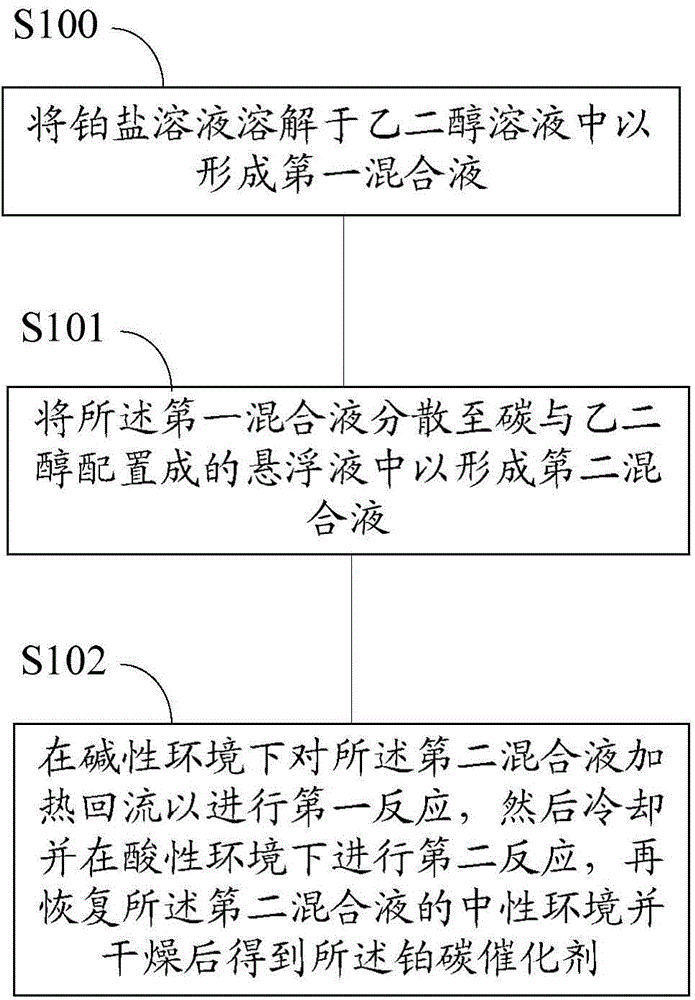

[0047] The application provides a method for preparing a platinum-carbon catalyst for a fuel cell, such as figure 1 shown, including the following steps:

[0048] Step S100, dissolving platinum salt solution in ethylene glycol solution to form a first mixed solution.

[0049] This application uses ethylene glycol (EG) solution as the reducing solvent, platinum salt compound as the precursor of platinum (Pt), and the mixture of platinum salt solution and ethylene glycol solution reduces platinum ions to pure platinum metal nanoparticles.

[0050] When using ethylene glycol as a reducing agent to prepare platinum metal particles, ethylene glycol plays an important role in the reaction. It is both a solvent and a weak reducing agent, and it acts as a surfactant to protect the reduced metal particles in the solution. .

[0051] In this step, the ethylene glycol solution is a mixed solution of deionized water and ethylene glycol, and the volume ratio of deionized water and ethyle...

Embodiment 1

[0089] Embodiment one is suitable for preparing platinum-carbon catalysts containing 50 wt% platinum:

[0090] At room temperature (25°C), 2g of platinum chloric acid hexahydrate (H 2 PtCl 6 6H2O, Sigma-adrich company) was formulated into 22.16wt% aqueous solution to form platinum chloric acid solution. 2.860 g of platinum chloride solution was extracted and dissolved in 10 ml of deionized water and 20 ml of ethylene glycol (EG) solution to form a first mixed solution.

[0091] Another 10 ml of deionized water and 20 ml of ethylene glycol solution were taken, and carbon (0.303 g, Kejtenblack) was dispersed in the solution by ultrasonic (instrument model 8892, Core-Parmer Company) to form a carbon suspension.

[0092] The preparation process includes:

[0093] First, add the first mixed solution into the uniform carbon suspension through the dropping funnel. After mixing and stirring evenly, adjust the pH value within the range of 10, raise the temperature to 160°C, and heat...

Embodiment 2

[0100] Example 2 is also suitable for preparing a platinum-carbon catalyst with a platinum content of 50 wt%. The difference from Example 1 is that the pH of the solution is adjusted to about 9 for the first time during the preparation process. At this point, the platinum carbon catalyst obtained:

[0101] After carrying out cyclic voltammetry test to this platinum-carbon particle catalyst, the electrochemical surface area obtained of described platinum-carbon particle catalyst is 58m 2 / gPt;

[0102] After the oxygen reduction test was carried out on the platinum carbon particle catalyst, the mass activity of the oxygen reduction reaction of the platinum carbon particle catalyst was 129mA / mgPt;

[0103] After the stability test of the platinum carbon particle catalyst, the electrochemical surface area loss of the platinum carbon particle catalyst was 15%, and the mass activity of the oxygen reduction reaction decreased to 22%.

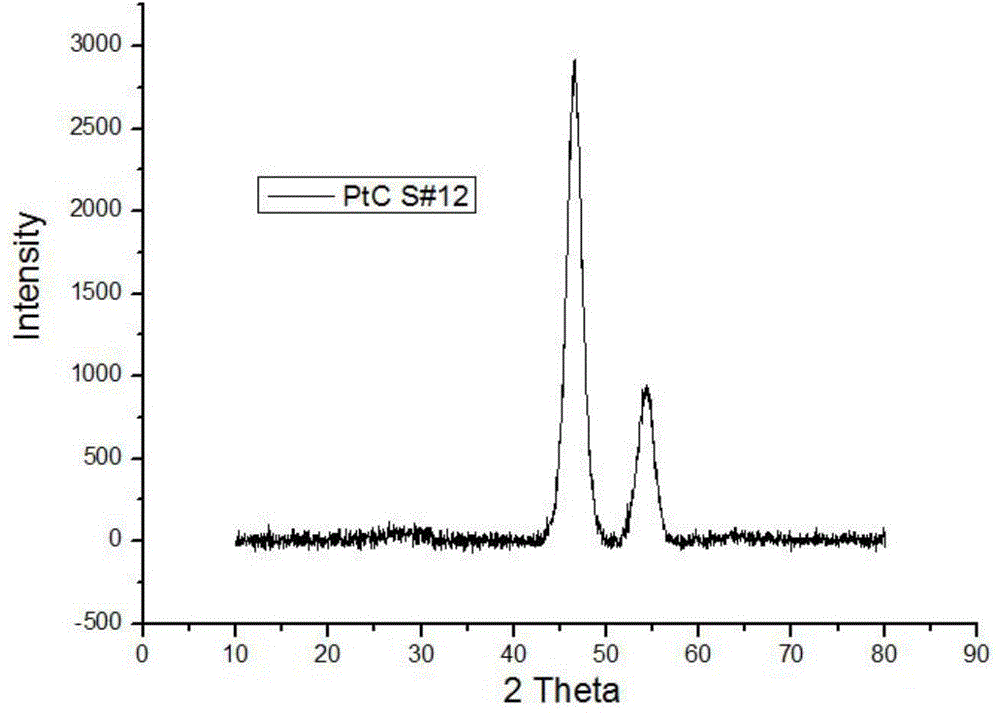

[0104] In addition, according to the width of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com