Special-tube-shaped electric heating apparatus and preparation method therefore

A technology of electric heating device and tubular structure, which is applied in immersion heating device, ohmic resistance heating parts, heating element shape, etc. It can solve the problem that the properties of alloy materials are not well understood, the key technology has not been mastered, and the application of electric heating tubes is not common. and other problems, to achieve the effect of good product quality, novel material selection and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

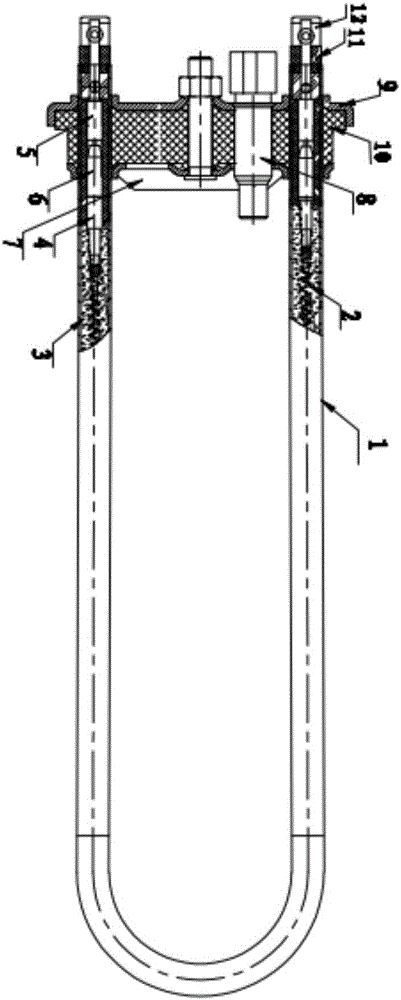

[0016] The main structure of the electric heating device with a special-shaped tubular structure involved in this embodiment includes an electric heating tube 1, an electric heating wire 2, magnesium oxide 3, an inner lead rod 4, an outer lead rod 5, a fuse 6, a pressure plate assembly 7, a thermal sensor 8, a method Lan 9, rubber sealing strip 10, insulator 11 and terminal 12, both ends of the hollow pipe-shaped electric heating tube 1 made of Ingrid 800 are equipped with overheating protection devices with the same structure, and the structure of the overheating protection device is sequentially arranged from the inside to the outside. Composed of heating wire 2, magnesium oxide 3, inner lead-out rod 4, outer lead-out rod 5, fuse 6 and insulator 11, one end of the heating wire 2 with coil structure is fixedly socketed on the inner lead-out rod 4, and the inner lead-out rod 4 and A fuse 6 is arranged between the outgoing rods 5 for automatic fusing when the temperature of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Insulation resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com