Centralized collection and classified treatment system and method for crumbled tobacco of leaf laying process in threshing and redrying technology

A technology of threshing and redrying and processing system, which is applied in chemical instruments and methods, treating tobacco, separating solids from solids with airflow, etc., which can solve the problems of proper handling of shredded tobacco, high impurity content of shredded tobacco, and poor purity and other problems to achieve the effect of alleviating the pressure of picking, improving the processing environment and improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

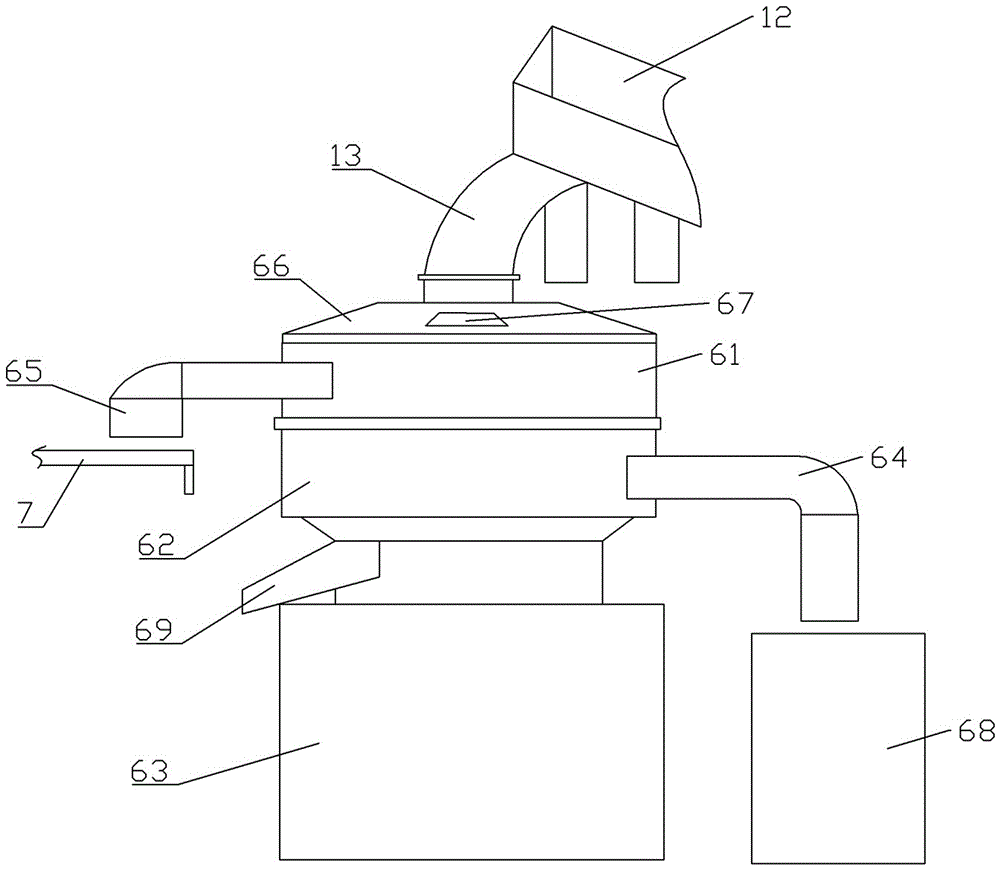

[0026] Preferably, a viewing window is also provided on the cover plate, which is convenient for observing the separation of crushed smoke and equipment maintenance.

[0027] The waste collection unit adopted above is a waste collection bucket, and the waste is treated separately after collection.

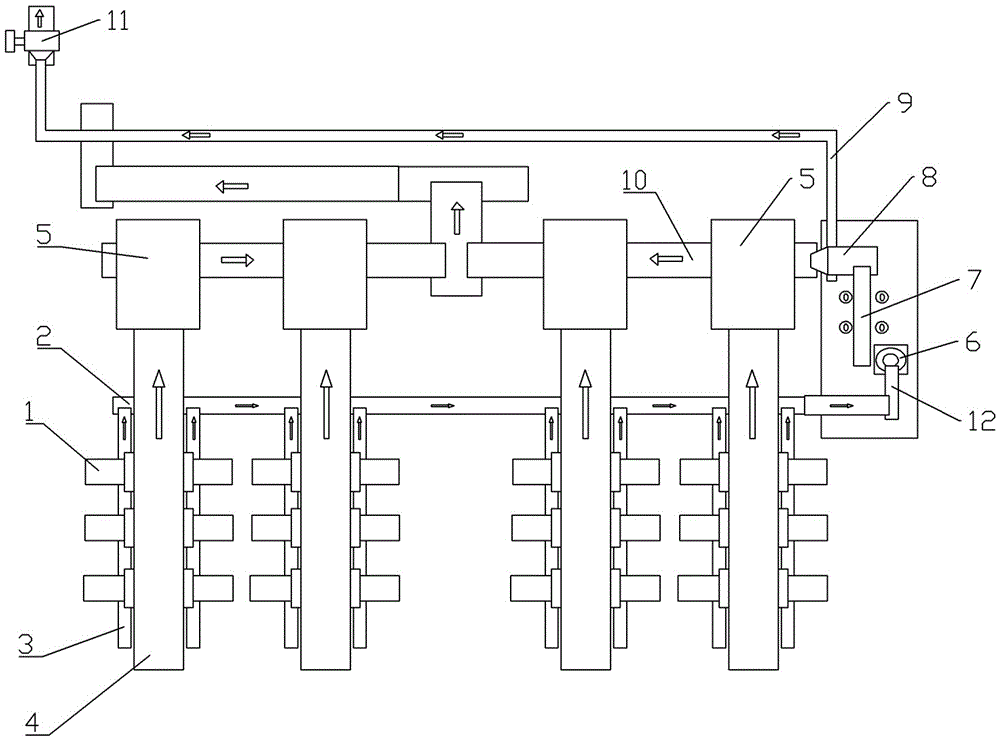

[0028] The conveyor used above includes a conveyor belt and a conveyor motor. One end of the conveyor belt is connected to the main conveyor belt, and the other end is provided with a feeding port. The feeding port is connected to the feed port of the vibration separation device through a conveying hose to reduce transportation costs.

[0029] Preferably, the conveying hose is a conveying cloth bag, one end of the conveying cloth bag communicates with the feed port, and the other end communicates with the feed port of the vibrating separation device to reduce dust pollution.

[0030] The system of the present invention has undergone repeated tests under the conditions of idling, lo...

Embodiment 2

[0034] b. In step a, the crushed smoke collected on each branch conveyor belt is sent to the main conveyor belt, and the collected crushed smoke is transported to the vibration separation device through the conveyor, and after vibration separation, the unidentifiable flax in the crushed smoke Impurities form lumps, and through the discharge port of the vibrating separation device, lump impurities and shredded smoke are sent to the slow-speed sorting belt. After manual sorting, the lump-like impurities are picked out from the shredded smoke, and the shredded smoke after picking out impurities passes through the The slow-speed picking belt enters the electromagnetic three-stage vibrating screen through the feed port of the electromagnetic three-stage vibrating screen for three-stage screening, and the blades larger than 6mm pass through the vibrating screen discharge port. The blades pass through the outlet of the vibrating screen and are transported to the blade screening link i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com