Method for preparing quasi-one-dimensional rare earth hexaboride nanowire

A hexaboride and nanowire technology, applied in the field of preparation of rare earth hexaboride nanowires, can solve the problems of complex preparation process, high preparation temperature, poor controllability of morphology, etc., and achieves important scientific value, simple process, easy The effect of transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

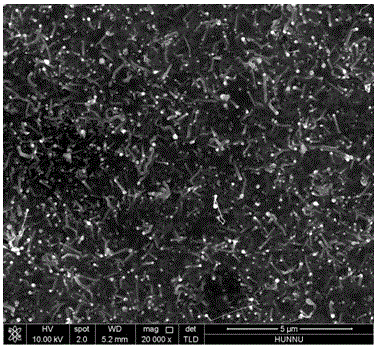

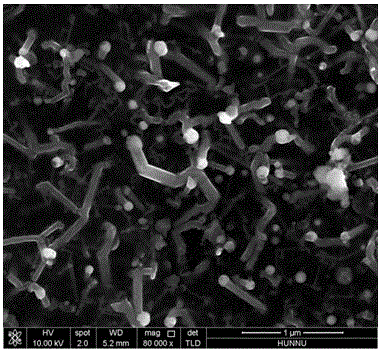

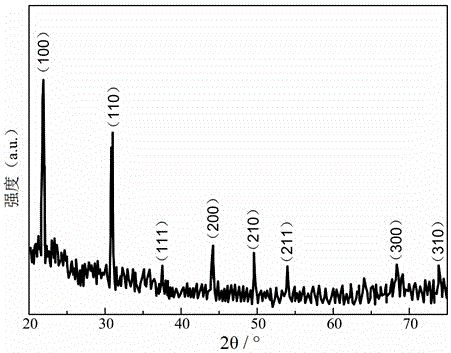

[0035] First place the silicon substrate in acetone, ultrasonically clean it for 5 minutes, then place it in absolute ethanol, ultrasonically clean it for 5 minutes, and finally place it in deionized water, ultrasonically clean it for 5 minutes, dry it naturally in the air, and set it aside.

[0036] (1) Add 1.35gKBH 4 Put it into the two straight-through corundum boats, put the corundum boat in the temperature zone 1 of the airflow direction on the corundum tube of the tubular electric furnace, and put 0.2g of anhydrous LaCl 3 Put it into another two-sided corundum boat, put the corundum boat in the temperature zone 2 of the airflow direction under the corundum tube of the tubular electric furnace, and place the silicon substrate in the temperature zone 2 without water LaCl 3 Then vacuum the corundum tube, then fill it with high-purity argon, repeat the gas washing for 3 times, and then continue to vacuum;

[0037] (2) At a flow rate of 60mL / min, pass high-purity argon gas i...

Embodiment 2

[0042] First place the silicon substrate in acetone, ultrasonically clean it for 8 minutes, then place it in absolute ethanol, ultrasonically clean it for 8 minutes, and finally place it in deionized water, ultrasonically clean it for 8 minutes, dry it naturally in the air, and set it aside.

[0043] (1) Add 1.06g NaBH 4 Put it into the two straight-through corundum boats, put the corundum boat in the temperature zone 1 of the airflow direction on the corundum tube of the tubular electric furnace, and put 0.1gCeCl 3 ·7H 2 O is placed in another corundum boat that is straight through at both ends, and the corundum boat is placed in the temperature zone 2 of the airflow direction under the corundum tube of the tubular electric furnace, and the silicon substrate is placed in the temperature zone 2. 3 ·7H 2 In the downflow direction of O, then vacuumize the corundum tube, then fill it with high-purity argon gas, repeat the gas washing for 5 times, and then continue to vacuumize;...

Embodiment 3

[0047] First place the silicon substrate in acetone, ultrasonically clean it for 10 minutes, then place it in absolute ethanol, ultrasonically clean it for 10 minutes, and finally place it in deionized water, ultrasonically clean it for 10 minutes, and let it dry naturally in the air for later use.

[0048] (1) Add 0.47gKBH 4 and 0.85g NaBH 4 Put the mixture of two straight-through corundum boats, put the corundum boat in the temperature zone 1 of the airflow direction on the corundum tube of the tubular electric furnace, and put 0.12g of anhydrous SmCl 3 Put it into another corundum boat with two straight ends, put the corundum boat in the temperature zone 2 of the airflow direction under the corundum tube of the tubular electric furnace, and place the silicon substrate in the temperature zone 2 of SmCl 3 Then vacuum the corundum tube, then fill it with high-purity argon, repeat the gas washing for 3 times, and then continue to vacuum;

[0049] (2) Inject high-purity argon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com