Method for high-efficiency separation of valuable metal ions in complex solution containing heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Efficient separation of heavy metal-containing solution

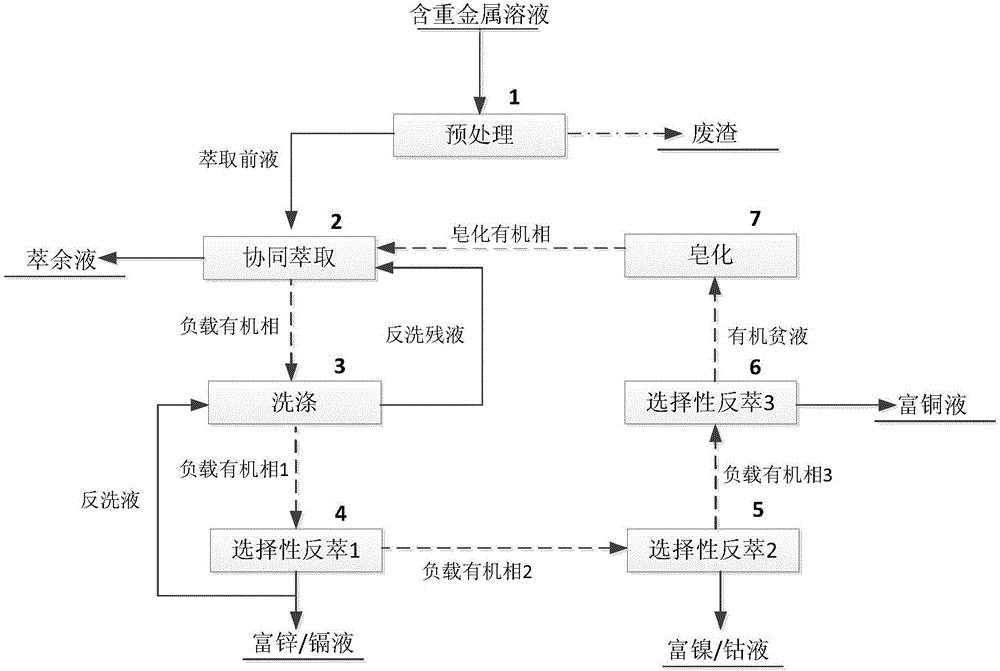

[0023] The heavy metal waste residue of a copper smelter in Zhejiang is leached with sulfuric acid. The leaching solution contains about 2g / L copper, 0.9g / L nickel, 16g / L zinc, 0.3g / L cadmium, 0.7g / L calcium and 8g magnesium. / L, the pH value is about 1.8. Adopt process of the present invention to process, flow process is as figure 1 As shown, unless otherwise specified, the comparison herein is the volume ratio of the organic phase to the aqueous phase, and the specific procedures are as follows:

[0024] (1) Add lime milk to the leaching solution to adjust the pH to about 5.4. The requirement of adding milk of lime to adjust the pH value in the method of the present invention is that the pH value of the solution should be as high as possible under the premise that the heavy metal ions in the solution do not undergo hydrolysis. Use grille and inclined plate sedimentation tanks for pretreatment to re...

Embodiment 2

[0032] Example 2 Efficient separation of heavy metal-containing solution

[0033] The leaching solution of purified slag from a zinc smelter in Zhejiang contains about 5g / L copper, about 0.3g / L nickel, about 0.8g / L cobalt, about 20g / L zinc, about 0.7g / L cadmium, and about 0.5g / L calcium. Magnesium is about 10g / L and the pH is about 1.0. Adopt process of the present invention to process, flow process is as figure 1 As shown, unless otherwise specified, the comparison herein is the volume ratio of the organic phase to the aqueous phase, and the specific procedures are as follows:

[0034] (1) Add lime milk to the leaching solution to adjust the pH to about 5.4. The requirement of adding milk of lime to adjust the pH value in the method of the present invention is that the pH value of the solution should be as high as possible under the premise that the heavy metal ions in the solution do not undergo hydrolysis. Use grille and inclined plate sedimentation tanks for pretreatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com